37

SECTION VIII

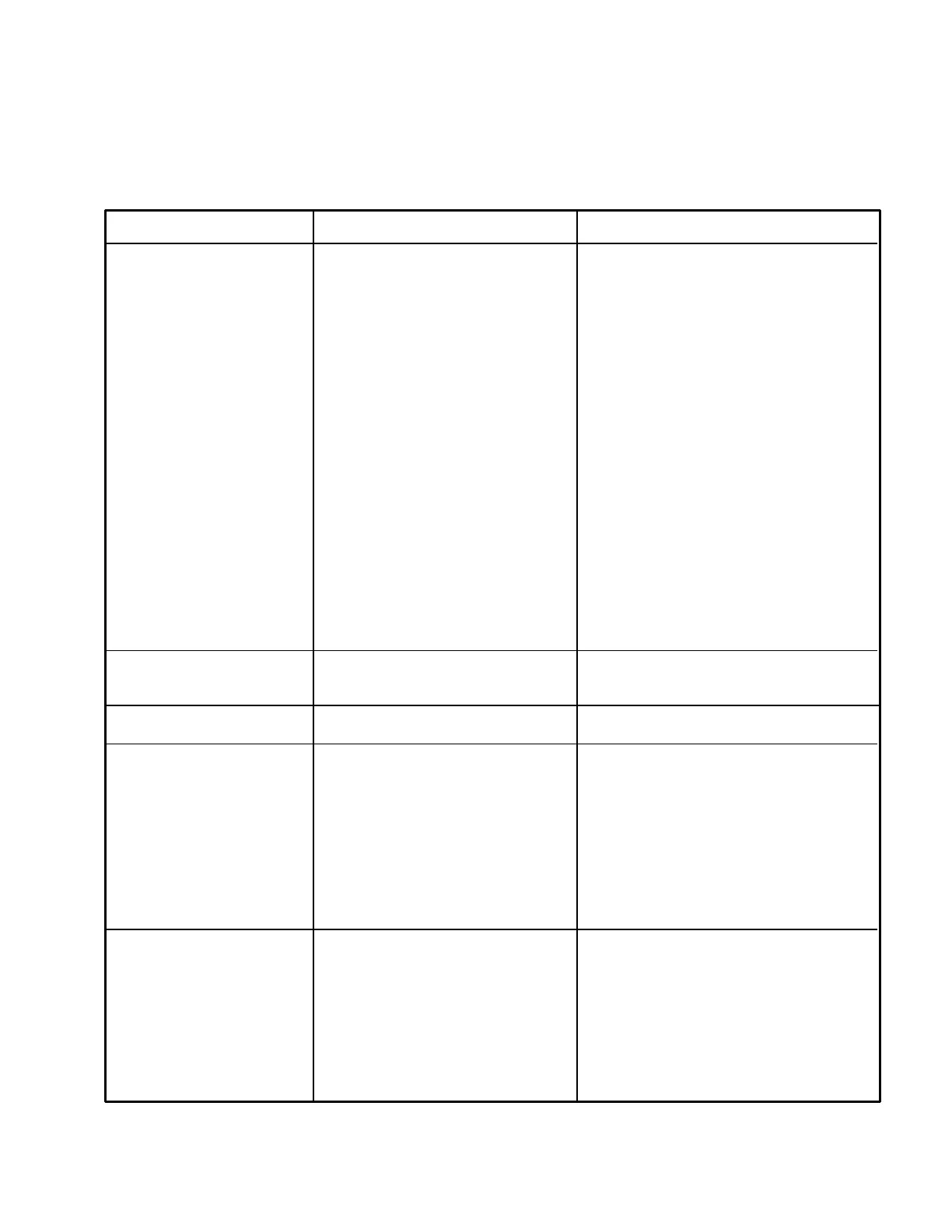

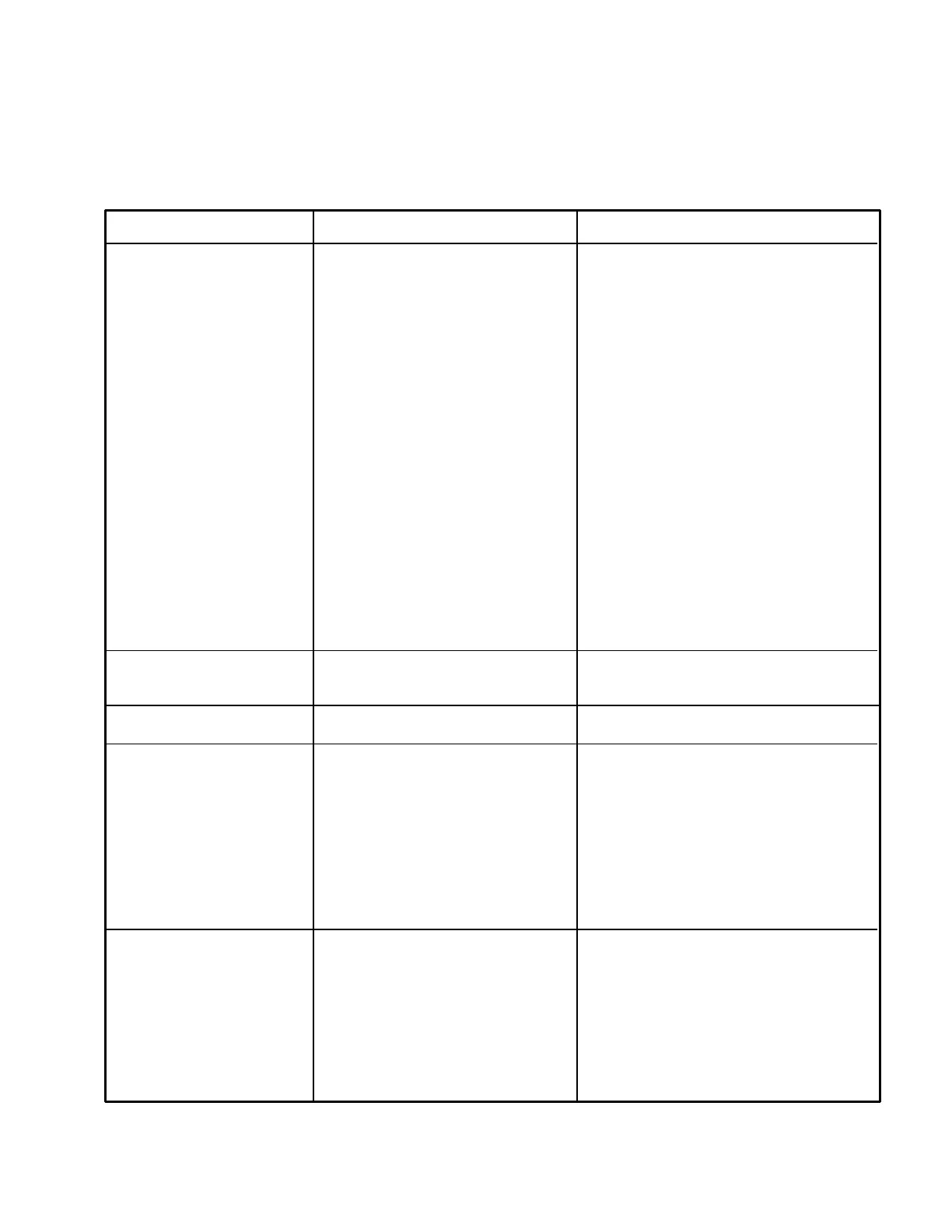

SERVICE DIAGNOSIS

MALFUNCTION POSSIBLE CAUSE REMEDY

Motor will not run 1. Blown branch circuit fuse. 1. Renew fuse(s).

2. Blown line disconnect fuse 2. Renew fuse(s) or reset

or tripped circuit breaker. circuit breaker.

3. Blown control circuit fuse(s). 3. Renew control circuit

fuse(s).

4. Magnetic starter overload 4. Reset overload relay(s).

relay tripped.

5. Loose or broken wires. 5. Check and repair or replace

(Motor or control) broken wire(s) and

connection(s).

6. Defective or damaged 6. Check components. Renew

control circuit components. as required.

(Relays, temperature

switches, etc.)

7. Damaged motor. 7. Repair or replace motor.

Air end will not rotate. 1. Defective or damaged air 1. Replace air end.

end.

Motor will not rotate. 1. Defective or damaged motor. 1. Replace or repair motor.

Air end/motor will not 1. Low line voltage or 1. Have qualified electrician

come up to full speed inadequate power check and correct power

before starter overload supply. supply.

trips.

2. Starting against pressure. 2. Check and correct cause of

Unit receiver not blown unit receiver not blowing

down. down. (Blow down valve:

controls).

Compressor fails to 1. Clogged or restricted air 1. Clean or renew air filter

provide sufficient air filter element. element.

for demands.

2. Excessive distribution 2. Correct air leaks as required.

system leakage.

3. Air demand exceeds 3. Reduce air demand. Install

compressor capacity. additional compressors.

Loading...

Loading...