9. Service and maintenance

47

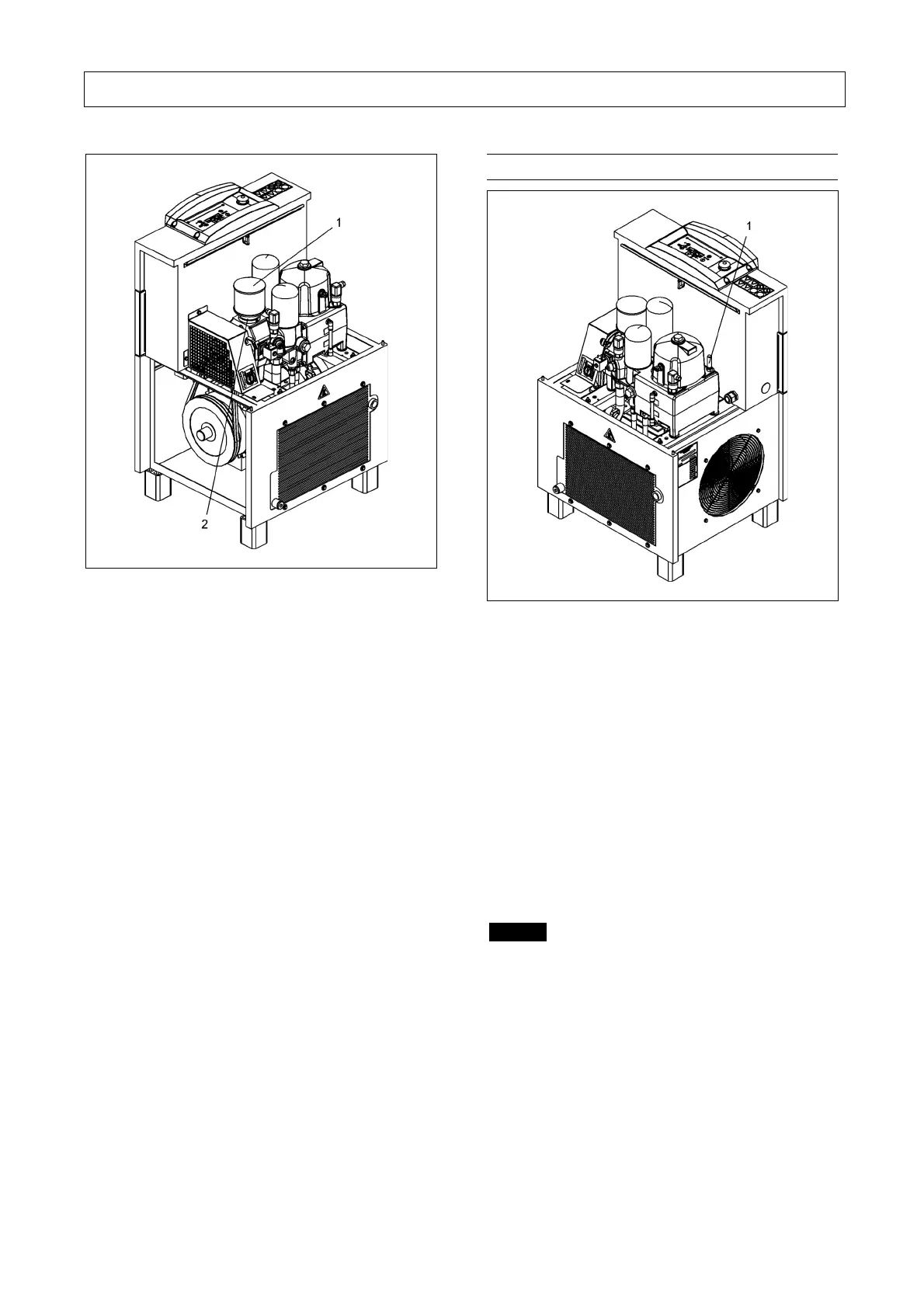

Fig. 20

1 Air filter

2 Fixing clip

Change the air filter as follows:

• Loosen screw at fixing clip ( - 2 - Fig. 20)

• Pull off the air filter ( - 1 - Fig. 20) and replace it with

a new one

• Retighten screw at fixing clip ( - 2 - Fig. 20).

Changing intervals for air filter cartridge

The operating conditions (e.g. coolant temperatures),

the operating modes and the quality of the intake air

(e.g. content of dust, content of gaseous foreign matter

such as SO2, solvent vapours, etc.) have a strong

influence on the service life of the filters (air filters, oil

filters, fine separators).

Where such conditions exist the filter element may

require changing more frequently.

9.8 Safety valve

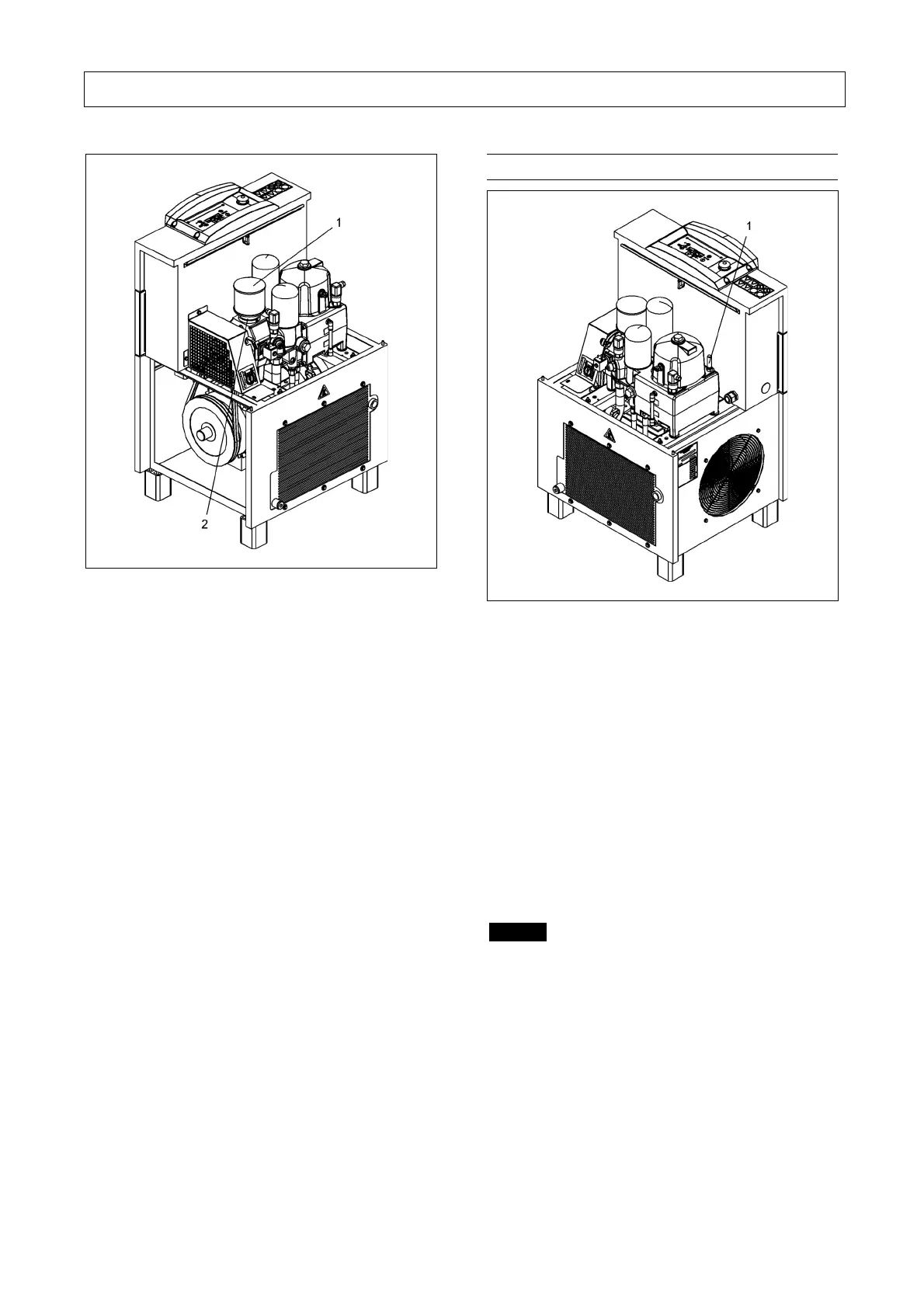

Fig. 21

1 Safety valve

Fig. 2b shows the safety valve of the L07FS-L11FS series.

Testing the safety valve

The valve should be tested on a separate compressed

air line in accordance with local legislation.

Operate the safety valve (-1- Fig. 21 ; -8- Fig. 2)

depending on the type of valve:

• by unscrewing the cap one or two turns and

retightening it

• or by pulling the valve lifting lever

Danger

Never operate a screw compressor system with a

defective safety valve or without safety valve!

Loading...

Loading...