ORIGINAL INSTRUCTIONS | Ref. quality process 002/03 | v. 22/09/2014 | K01068

16

11. MAINTENANCE

11.1.Generalwarning

Before performing any type of maintenance you should:

• Always turn OFF the main power switch to the OFF position ( ).

• If the grinder is jammed, unplug it from the power source and contact an

authorizedservicetechnician.

Not following these warnings can compromise the safety of the grinder as well as

the user.

11.2.Generalmaintenanceofthegrindchamber

To guarantee the efciency and correct operation of the grinder, it is essential to

follow manufacturer instructions and ensure that all maintenance work is carried

outbyqualiedstaff.

Dull burrs will result in; a lower quality grind, greater heat generation in the coffee

andgrinder,increasedelectricalconsumption,andnallyitputsadditionalstresson

the grinder motor.

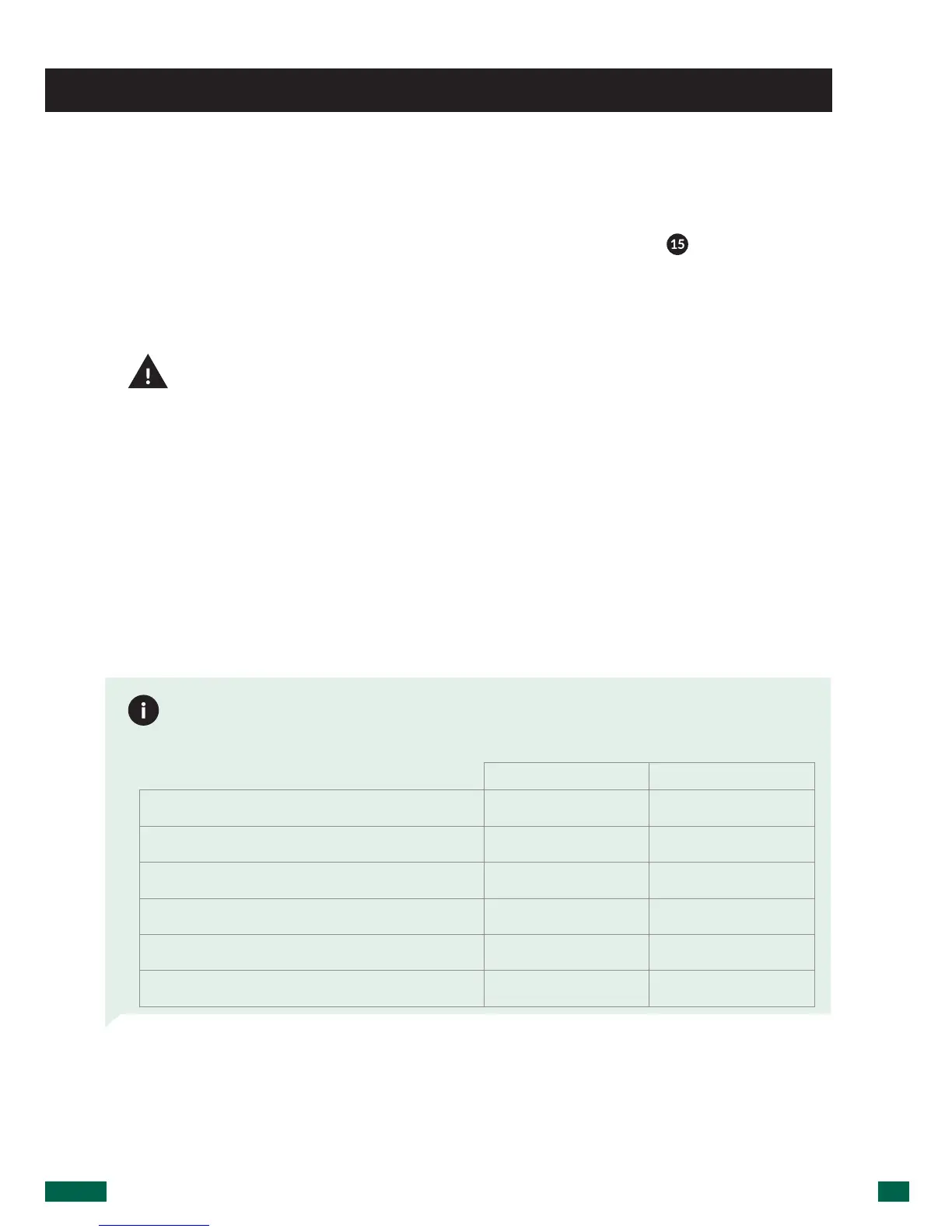

NOTE: Based on extensive experience and a medium-hard coffee blend, we

recommend replacing the burrs after grinding 350 Kg/770 lb of coffee.

Burrschange RedSpeedLucidate

K3, K3 ELITE

300 Kg

K6, K6 PB

400 Kg

K6 SILENZIO

400 Kg

K8 SILENZIO

800 Kg 3500 Kg

K10 CONIC, K10 CONIC PB

1200 Kg 7500 Kg

K10 MASTER CONIC, K10 MASTER CONIC PB

1200 Kg 7500 Kg

Loading...

Loading...