35COMPRAG Schraubenkompressoren A-Serie

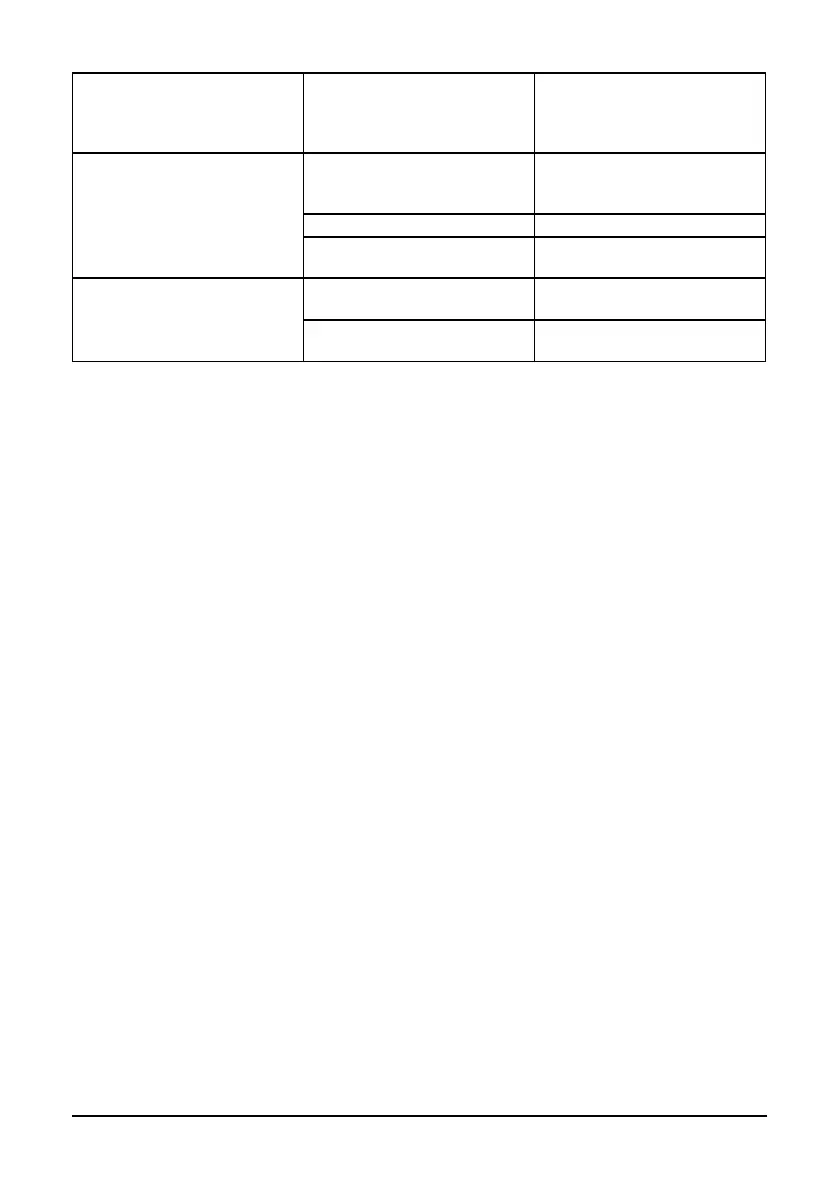

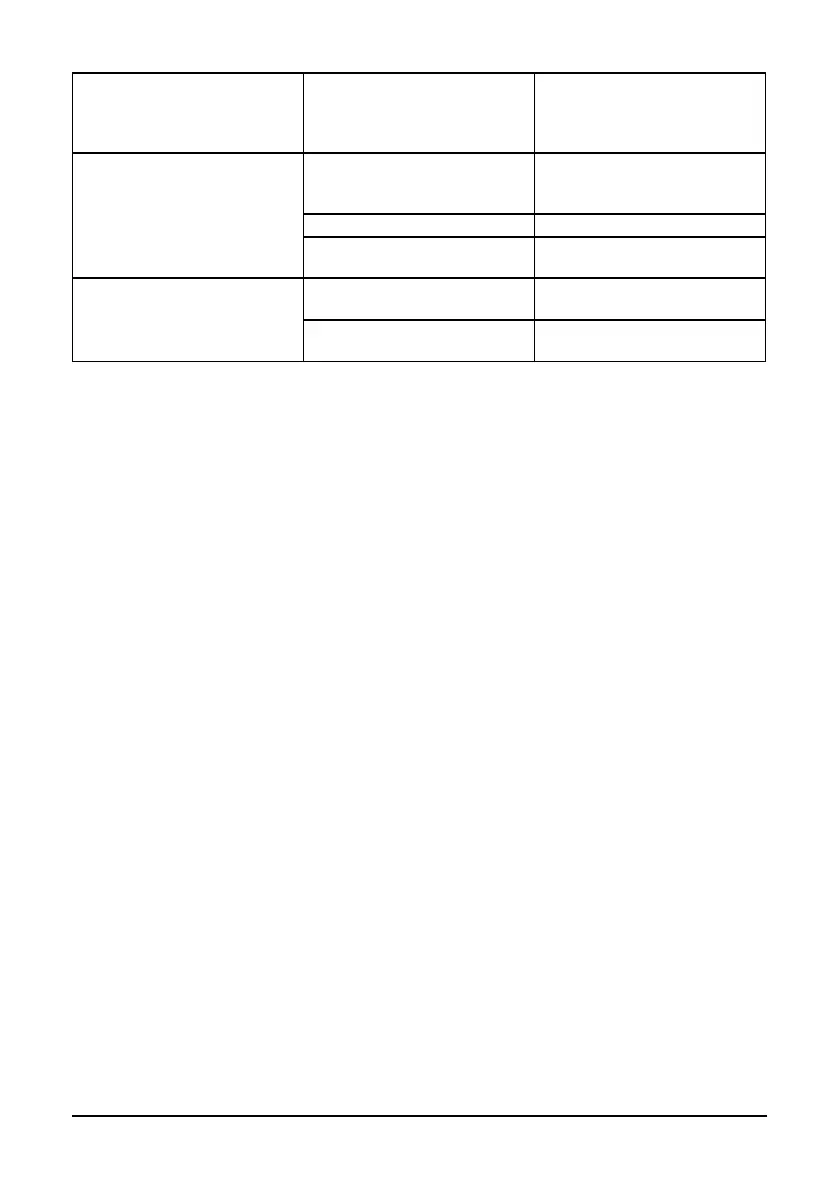

The compressor won’t start.

There’s a temperature block on

the control unit’s display.

The ambient air temperature in

the facility does not meet the

required temperature (below +5

°C or above +40 °C).

Ensure the necessary ambi-

ent air temperature where the

compressor is installed.

The compressor is overheating.

There’s insufcient ventilation in

the facility where the compres-

sor is installed.

Increase the air circulation

inside the facility.

The oil level is too low. Top up oil.

The radiator is dirty.

Blow down the radiator with

compressed air.

The safety-relief valve of the

separator tank is activated.

The separator is dirty.

Perform maintenance by replac-

ing the separator.

The pressure is too high (over13

bar).

Set the working pressure below

13 bar.

7. Storage and disposal

7.1 Storage conditions

The compressor should be kept at a temperature between -20° and +35°С with max. 85%

relative humidity.

7.2. Disposal of oils and process condensate.

Used oils, greasy lters and separators should be recycled in a sealed container and dis-

posed of at a local recycling or disposal facility. Do not allow precipitation to mix with oil.

Process condensate contains oil. Local environmental regulations govern the degree of

contamination of condensate discharge into sewers. Use process condensate separators to

separate oil and further impurities from condensate.

Replaceable components of a process condensate separator should be disposed of in the

same way as greasy wiping cloths.

Loading...

Loading...