13COMPRAG Screw air compressor A-Series

2.4 Functional description (see Fig. 2.1 and Fig. 2.2)

Air ow:

Air drawn through Air lter (4) and open Intake valve (5) into compressor Air-end (3) is compressed.

Compressed air and oil ow into Air-Oil separation tank (6). The air is discharged via Min.

Pressure valve (11) through Heat-exchanger (13) towards the Air Outlet Valve (20).

Oil ow:

Air pressure forces oil from the air-oil separation tank (6) through the heat-exchanger (14)

and the oil lter (16) to the compressor air-end (3) and the lubrication points. In the air-oil

separation tank (6), most of the oil is removed centrifugally; the rest is removed by the

air-oil separator (8).

The oil system is tted with a thermostatic valve (15). When the oil temperature is below

the set-point of the thermostatic valve, the thermostatic valve shuts off the oil supply

from oil heat-exchanger (14). The thermostatic valve starts opening the supply from heat-

exchanger (14) when the oil temperature exceeds the valve’s setting. The setting of the

thermostatic valve depends on the model. See table Technical Data.

Cooling system:

The cooling system comprises a combined air section (13) and an oil section (14) heat-

exchanger. A cooling fan, mounted directly on the motor shaft, generates the cooling air in

order to cool the heat-exchanger.

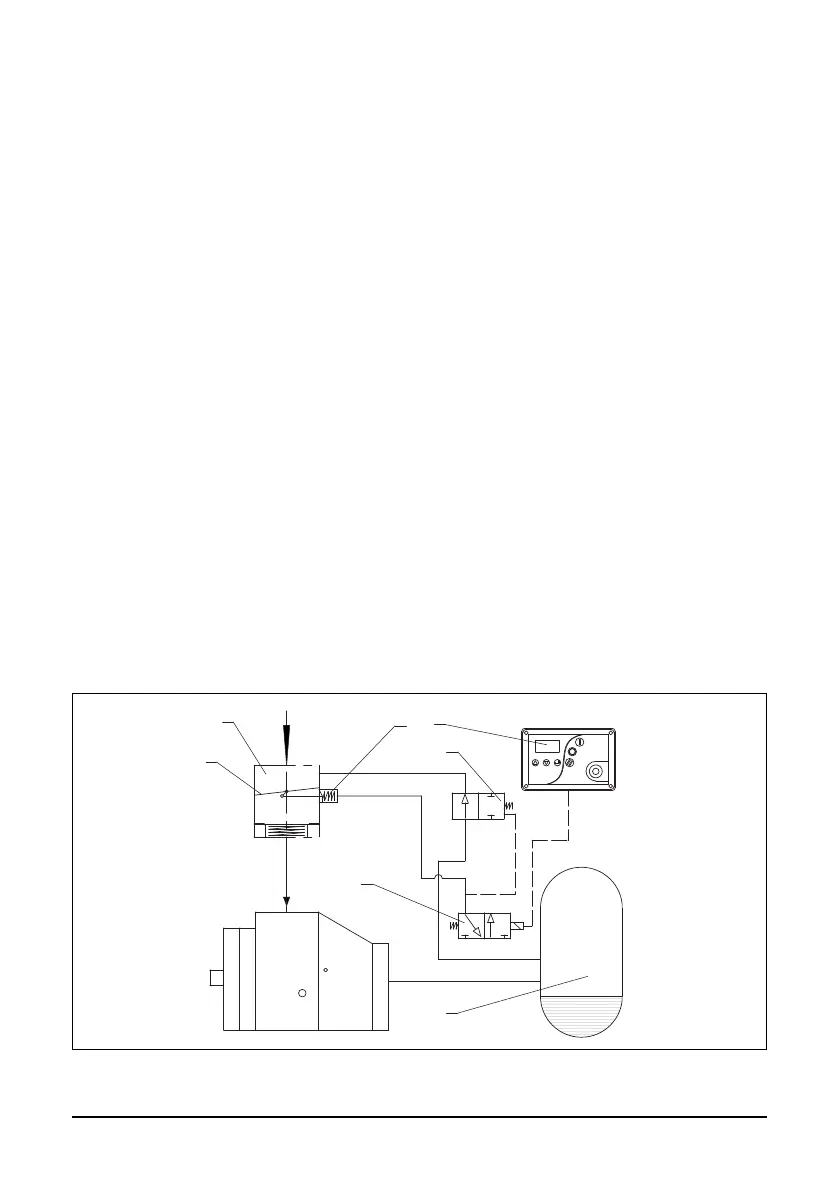

2.5 Regulating system

Fig. 2.3 Regulating system

Loading...

Loading...