39

COMUNELLO ®Copyright 2019 - All rights reserved

ENGLISH

procedure.

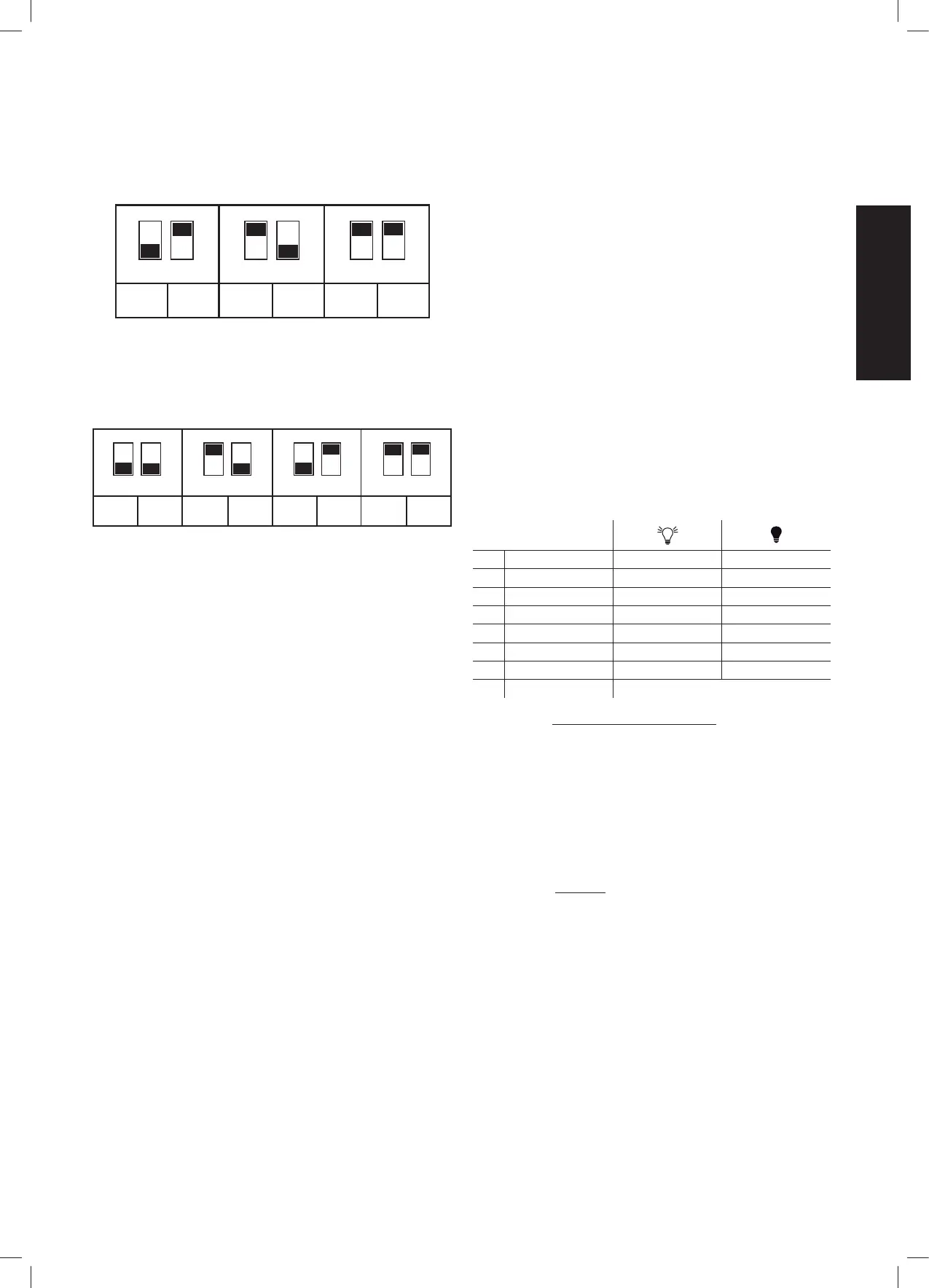

7.3.1 MOTOR 1 OR MOTOR 2 DELAY CONTROL AND ENABLING OF 1

OR 2 MOTORS

1

1

ON

2

MOTOR

NOT

CONSID.

2

MOTORS

MOTOR

2 DELAY

2

MOTORS

MOTOR

1 DELAY

1

ON

2 1

ON

2

SW1 SW1 SW1

The electronic control unit is equipped with a dip-switch SW1 that is used to

select operation with 1 or 2 motors and to dene which of the two starts rst

and which starts second.

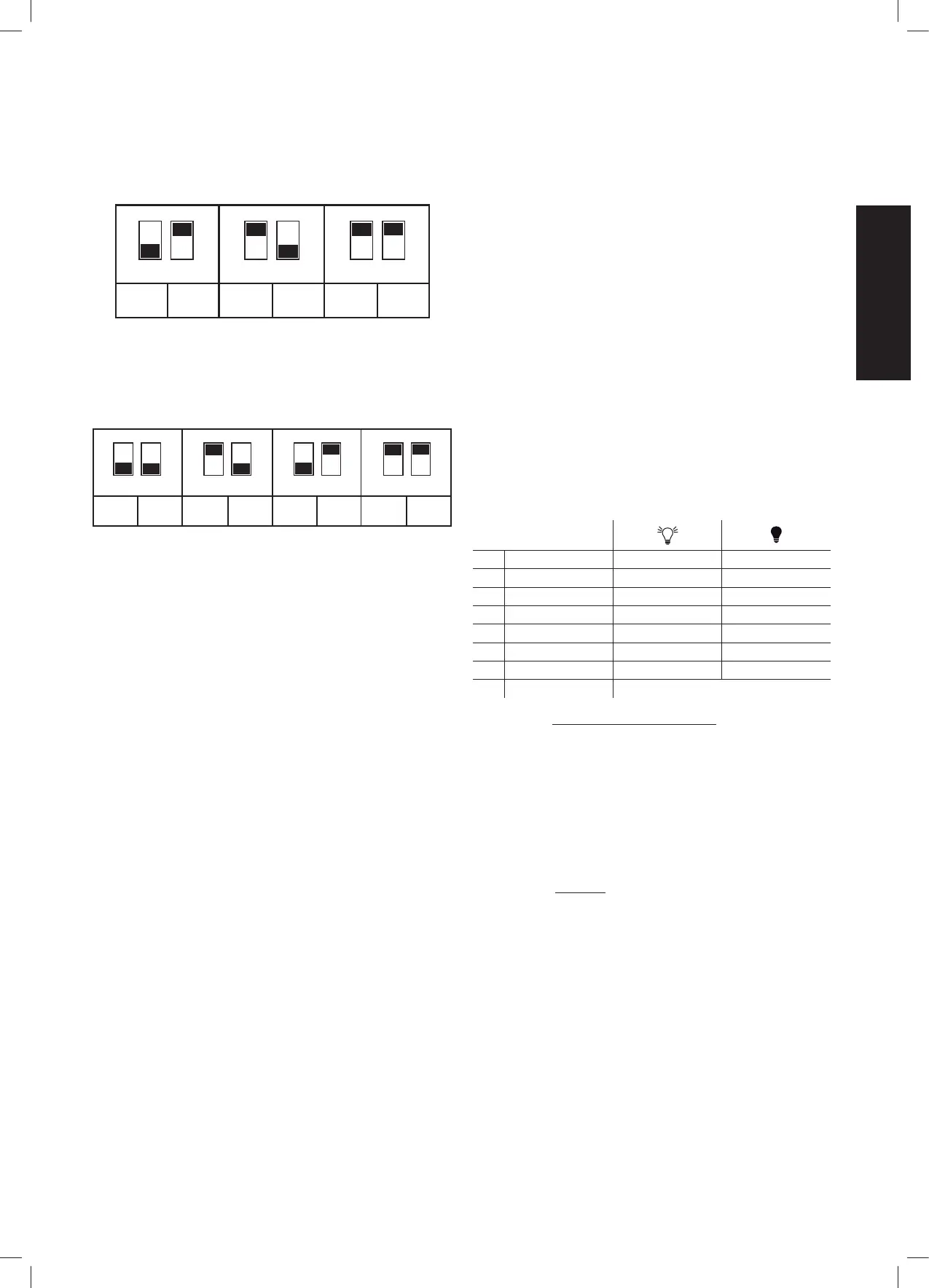

7.3.2 MOTOR 1 AND MOTOR 2 STROKE DIRECTION

INV

OFF

INV

OFF

INV

MOT 1

INV

OFF

INV

OFF

INV

MOT 2

INV

MOT 1

INV

MOT 2

1

ON

21

ON

2 1

ON

2 1

ON

2

SW2 SW2 SW2 SW2

The electronic control unit is equipped with dip-switches that can be used

to change the stroke direction of each connected motor without rewiring

the electrical connections: dip-switch 1 controls Motor 1 while dip-switch 2

controls Motor 2.

7.3.3 DECELERATION (SLOWING):

The motor deceleration function is used in the gates to prevent the mobile

doors from striking at high speed at the end of opening and closure.

When programming the Motor Time, the control unit also allows deceleration

to be programmed in the desired points (before total opening and closure).

Moreover, through the “SLOWING” trimmer it is possible to choose from three

deceleration speed values.

7.3.4. REGULATION OF MOTOR POWER (FORCE):

The electronic control unit is equipped with a “SPEED” trimmer for

adjustment of the speed delivered by the Motors, completely managed by

the microprocessor.

Adjustment can be performed in a range between 50% and 100% of

maximum speed.

Initial starting torque can be set for each movement by feeding the operator

at full power for 2 seconds, even if operator speed control is enabled.

Important notes:

- Initial starting torque is disabled automatically if the Soft Start function is

enabled (see section 8.4.2.);

- A variation of the trimmer “SLOWING” requires the repetition of the learning

procedure, since the times of manoeuvre and slowing may vary.

7.3.5. OBSTACLE DETECTION (ONLY IN VERSION WITH ENCODER):

The electronic control unit is equipped with a “SENS” trimmer, completely

managed by the microprocessor, for adjustment of the opposing Force required

to detect the presence of an obstacle. The adjustment can be made with a trip

time from a minimum of 0.1 seconds to a maximum of 7 seconds

Important notes:

- In the presence of limit switches connected to the control unit, the detection

of the obstacle always causes the reversal of the closing movement and the

inversion for 2 seconds in opening.

- The detection of an obstacle causes the brief inversion of movement in

closure and opening.

- In the absence of limit switches connected to the control unit, detection of

an obstacle will always cause a brief inversion of direction except in the last 5

seconds of the manoeuvre, in which case a stop will be made.

7.3.6 BLACK-OUT

In the case of a black-out and subsequent restoration of the power supply,

the rst manoeuvre will be in opening with a xed speed as set by the trimmer

“SLOWING”; when a mechanical block is encountered, in the absence of an

electrical limit switch, the doors will not be obstructed, but will execute a STOP

(version with encoder). With a subsequent command, the doors will close again

at reduced speed until completely closed. The next manoeuvre will be at the

speeds set by the trimmers.

8 DETAILED DESCRIPTION OF THE

PROGRAMMING

PROGRAMMING:

SELECT key: it determines the type of function to be memorized, as indicated

by the blinking of the LED.

By pressing the key several times, it is possible to scroll the menu and move to

the desired function. The selection remains active for 10 seconds, displayed by

the ashing LED; when this interval elapses, the control unit exits programming.

SET key: it conrms and changes the programming according to the type of

function determined by the SELECT key.

Following conrmation, the respective LED remains on / off for about 2 sec. and

then starts ashing again.

Important notes: the function of the SET key can also be replaced by the remote

control if previously programmed (LED L2 CODE TX lit).

Programming enabled only with the closure of N.C contacts enabled.

8.1 MAIN MENU

L1 STEP BY STEP Step-by-step Automatic (Open-Close)

L2 CODE TX Remote control stored No remote control stored

L3 CONDO ON OFF

L4 MOTOR TIME Complete stroke stored 30 s. (no slowdowns)

L5 PAUSE TIME With automatic closure OFF

L6 DELAY ON OFF

L7 PRG AUTOM ON OFF

LEV MENÙ ON

8.1.1 LED L1 - STEP BY STEP or OPEN-CLOSE:

Programming

In the default conguration the control unit is set with “Step-By-Step”

operating logic enabled (LED no.1 ON);

if the “Automatic Open-Close” operating logic is required (LED no.2 OFF),

proceed as follows:

• By the key SELECT, position yourself on the blinking LED no.1;

• Press the SET key;

• The LED L1 turns off and programming will be completed.

Repeat the procedure if you wish to restore the previous conguration.

8.1.1. LED L2 - CODE TX:

CODE TX: Remote controls storage

Up to 120 remotes with different codes of either the xed or the rolling code

type can be saved on the control unit

Remote control code programming of the total opening (Mot. no. 1 + Mot.

no.2):

• By the key SELECT, position yourself on the blinking LED 2 “CODE TX”;

• Press key SET once to memorize the PP channel;

• Send the selected code with the remote control;

• The LED L2 will remain steady on for a second to indicate that

programming has been completed;

• The LED L2 starts to blink again to indicate that you have 10 additional

sec. to store a new code;

• On expiry of those 10 sec.the LED L2 will remain steady on.

Remote control code programming of the partial / pedestrian opening

(Mot. no. 1):

• By the key SELECT, position yourself on the blinking LED L2 “CODE TX”;

• Press key SET twice to memorize the PPED channel and the led will

modify its blinking (110110110);

Loading...

Loading...