2VA/AVA/AF IO&M B51146-004

3. Position isolators under fan and secure bolts.

4. Remove blocks and allow fan to rest on oor. Isolators

must be installed on a level surface (leveling should

not be required).

5. Secure isolators to mounting surface.

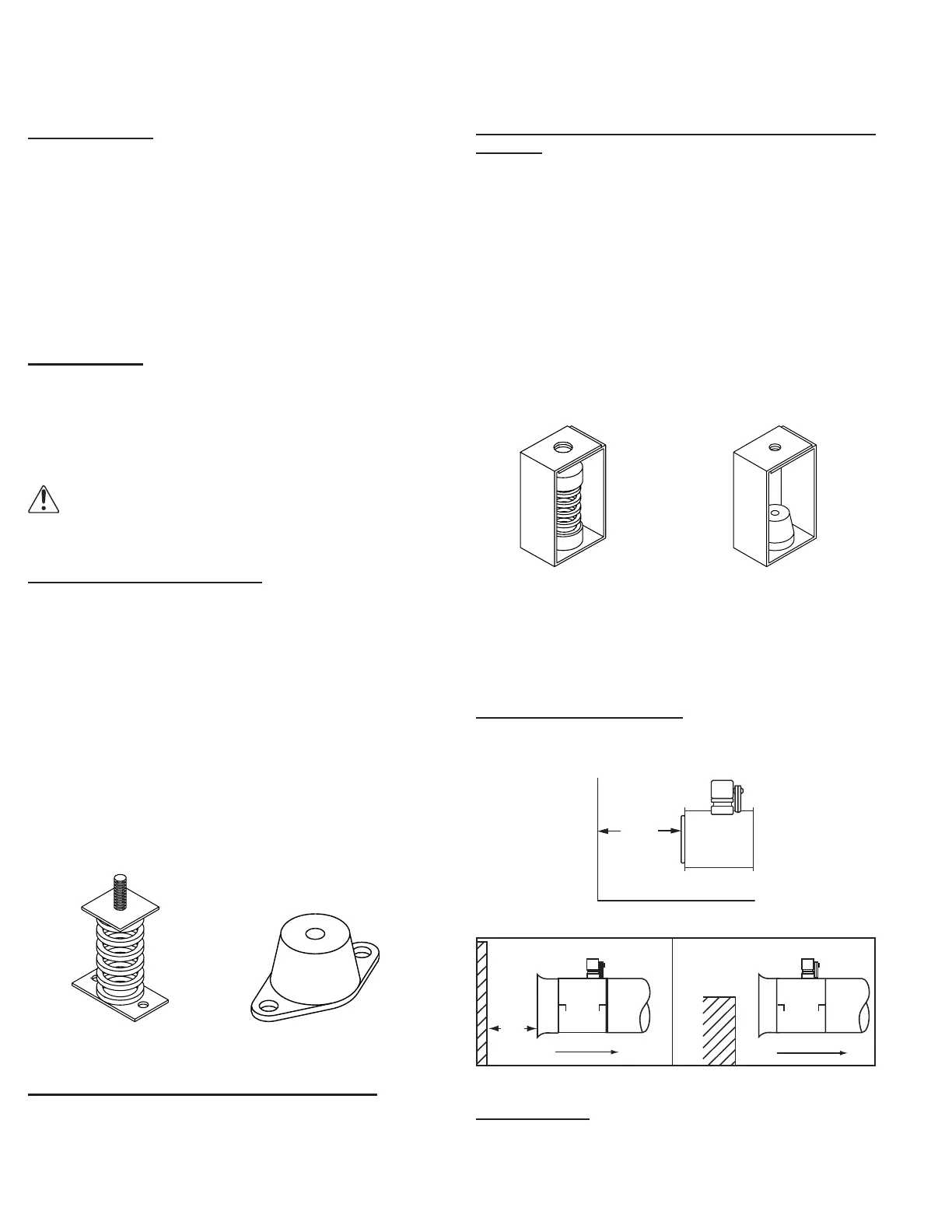

Ceiling Mounted Spring and Rubber-in-Shear (RIS)

Isolators

1. Elevate fan to operating height and brace.

2. Attach threaded rod to overhead support structure di-

rectly above each mounting hole. Rod should extend

to within a few feet of fan.

3. Attach isolator to end of threaded rod using a nut on

each side of isolator bracket.

4. Insert another section of threaded rod through the fan

mounting hole and isolator.

5. Attach two nuts to threaded rod in isolator.

6. Place adjusting nut and locking nut on threaded rod

near fan mounting bracket.

7. Alternately rotate adjusting nut at each mounting loca-

tion until the fan weight is uniformly transferred to the

isolators. Remove bracing.

Ceiling Mounted Spring Isolator Rubber-in-Shear Ceiling Isolator

Figure 2 - Ceiling Mount Isolators

Duct Installation

Ecient fan performance relies on the proper installa-

tion of inlet and discharge ducts. Be sure your fan con-

forms to the following guidelines.

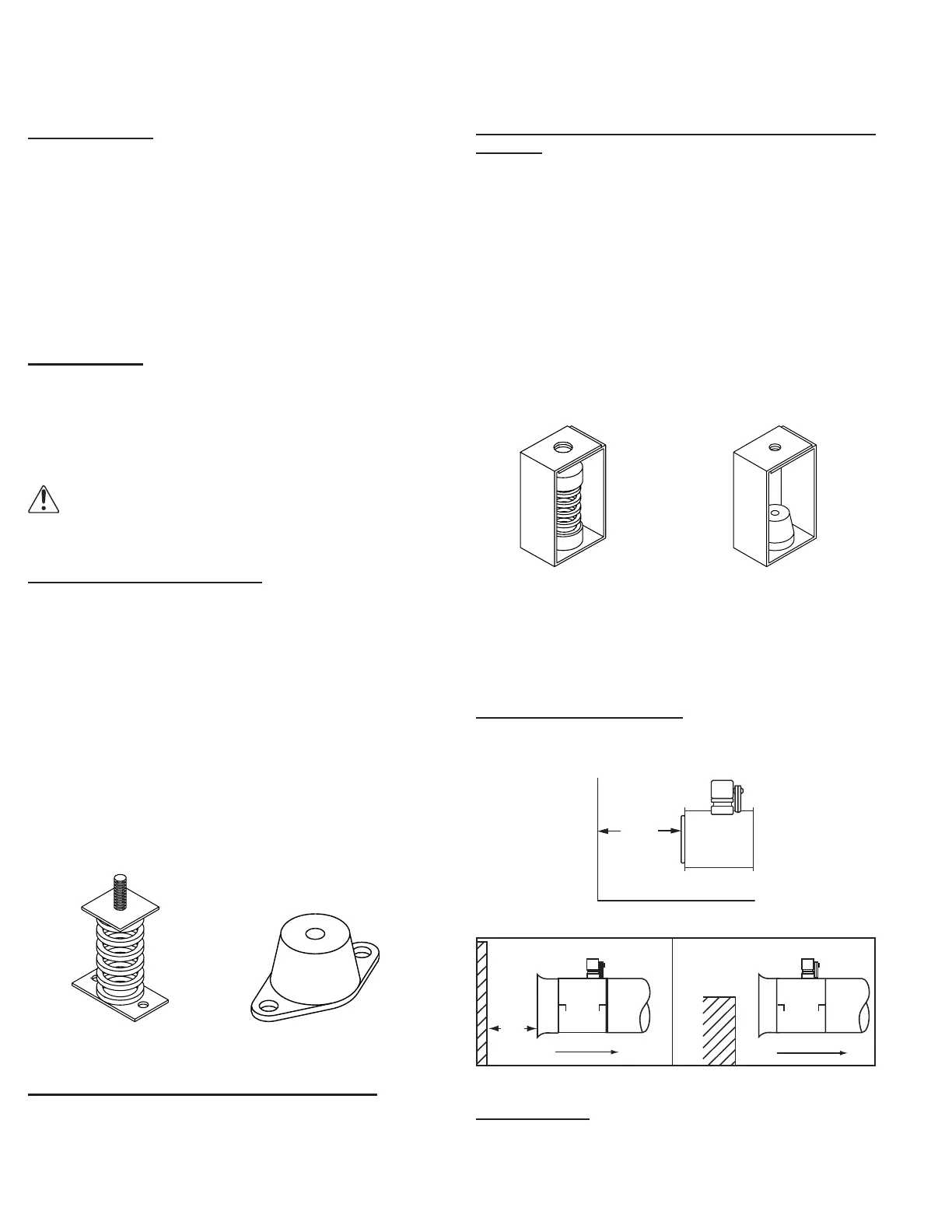

Non-Ducted Inlet Clearance

If your fan has an open inlet (no duct work), the fan must

be placed one fan wheel diameter away from walls and

bulkheads.

MIN

1 DIA

Non-ducted Inlet Clearance

Air Flow

Correct

Inlet Bell

Fan

Inlet Bell

Air Flow

Incorrect

Fan

Min

1 Dia.

Inlet Bell

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost eciency because it doesn’t allow for a static regain.

Storage

If the fan is stored for any length of time prior to installa-

tion, completely ll the bearings with grease or moisture-

inhibiting oil (refer to Lubrication, pages 6-7).Store the fan in

its original crate and protect it from dust, debris and weather.

Outdoor Storage

To maintain good working condition of a Vane Axial fan

when it is stored outdoors or on a construction site, follow

the additional steps below.

• Cover the inlet and outlet and belt tunnel opening to pre-

vent the accumulation of dirt and moisture in the housing.

• Periodically rotate the prop and operate dampers (if sup-

plied) to keep a coating of grease on all internal bearing

parts.

• Periodically inspect the unit to prevent damaging

conditions.

Installation

To prevent damage to the fan during shipping, motors

25 HP and larger and extremely heavy motors (cast iron or

severe duty) are shipped loose and must be eld mounted

by bolting the motor on the motor mounting plate in the ex-

isting mounting slots.

NOTICE! Extreme vibration is a serious problem

that may cause structural and mechanical failure.

To help vibration and noise from being transferred

to the building, isolators are recommended.

Isolation Installation

Floor Mounted Spring Isolators

1. Mount fan and motor on unitary base (if supplied).

2. Elevate fan (or isolation base) to operating height and

insert blocks to hold in position.

3. Position isolators under the fan and vertically align by

inserting leveling bolt through mounting holes in the

fan or the base. The isolator must be installed on a

level surface.

4. Adjust the isolators by turning the leveling nut counter-

clockwise several turns at a time alternately on each

isolator until the fan weight is transferred onto the iso-

lators and the fan raises uniformly o the blocks. Then

remove the blocks.

5. Turn lock nut onto leveling bolt and secure rmly in

place against the top of the mounting ange or frame.

6. Secure isolators to mounting surface.

Spring Isolator Rubber-in-Shear Isolator

Figure 1 - Floor Mount Isolators

Floor Mounted Rubber-In-Shear (RIS) Isolators

1. Mount fan and motor on a unitary isolation base (if

supplied).

2. Elevate fan to provide room to insert isolators between

the fan and foundation and block in position.

Loading...

Loading...