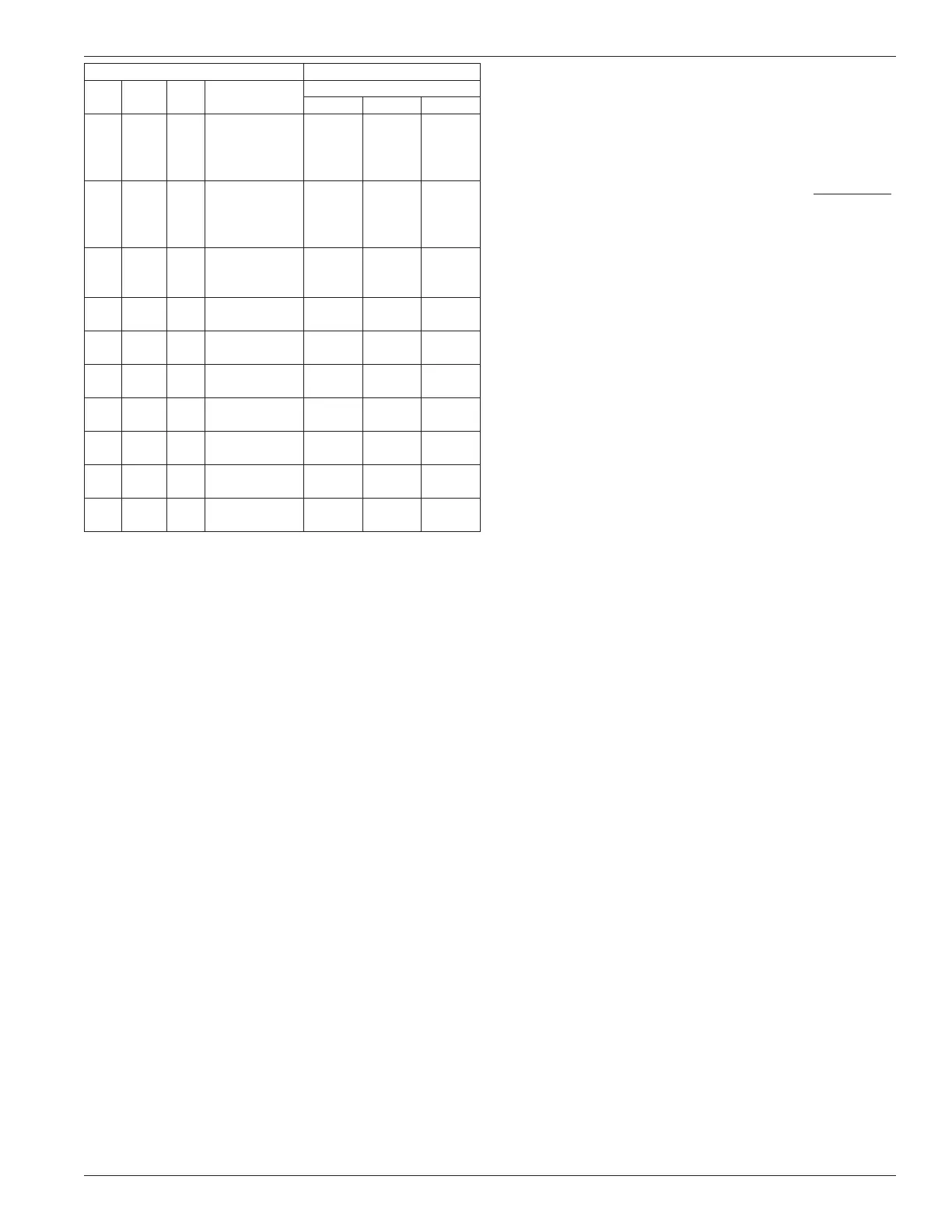

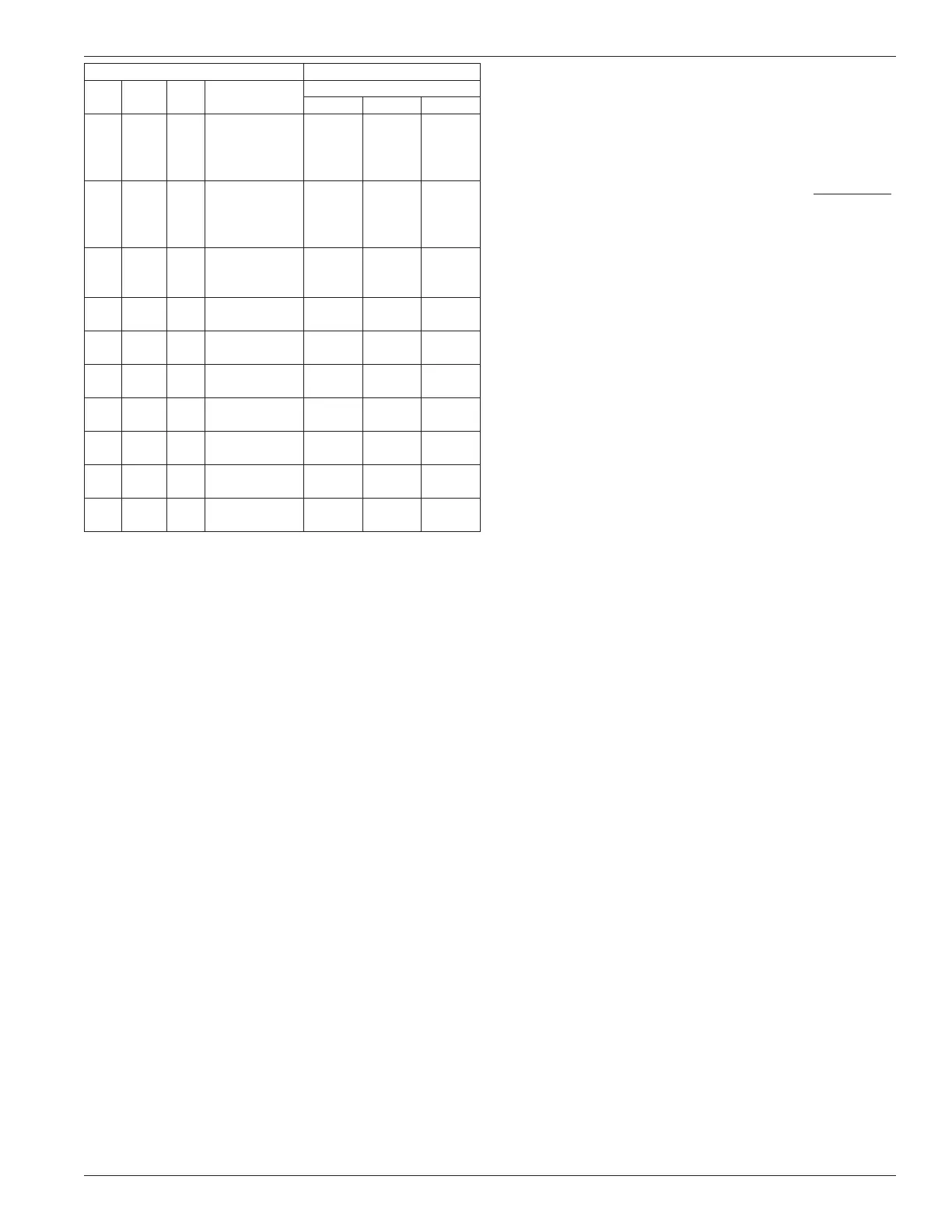

Motor Recommended wire size, AWG

1

Hp Motor

Phase

Volts Approximate Full

Load Amperes

Length of Run (ft)

0–100 to 200 to 300

3 1 115 34.0 6 4 2

220 17. 0 12 8 8

3 230 9.6 12 12 12

460 4.8 12 12 12

5 1 115 56.0 4 1 1/0

230 28.0 10 6 4

3 230 15.2 12 12 10

460 7.6 12 12 12

7-1/2 1 230 40.0 8 6 4

3 230 22.0 10 10 8

450 11.0 12 12 12

10 3 230 28.0 8 8 8

460 14.0 12 12 12

15 3 230 42.0 6 6 6

460 21.0 10 10 10

20 3 230 54.0 4 4 4

460 27.0 8 8 8

25 3 230 68.0 2 2 2

460 34.0 6 6 6

30 3 230 80.0 1 1 1

460 40.0 6 6 6

40 3 230 100.0 2/0 2/0 2/0

460 52.0 4 4 4

50 3 230 130.0 3/0 3/0 3/0

460 65.0 2 2 2

1

Based upon 3% voltage loss copper wire type TW. Single phase motor

calculations are based on two times distance.

Improper motor wiring will cause expensive motor

difficulties from low voltage. If you suspect you have

low voltage, call your power company. Connecting your

motor for the voltage you have available is important

too. The motors furnished with the stationary pumps are

usually dual voltage, so you must be sure of the voltage

your power company is supplying you. Your motor will be

completely ruined if it is connected to the wrong voltage.

A humid climate can cause problems, particularly in

explosion proof motor applications. The normal breathing

of the motor, and alternating between being warm when

running and cool when stopped, often will cause moist

air to be drawn into the motor housing. This moist air will

condense, and may eventually add enough free water

to the inside of the motor to cause it to fail. To prevent

this, make a practice of running the motor and pump at

least once a week on a bright, dry day for an hour or so

(pumping through the bypass system). In this period the

motor will heat up and vaporize the condensed moisture,

and drive it out of the motor. No motor manufacturer will

guarantee an explosion proof or totally enclosed motor

against damage from moisture.

Engine drivers pose a special consideration. The

manufacturer’s instructions must be followed. When the

stationary pump is equipped with an engine from the

factory, the engine speed should normally not exceed

1,800 RPM. Excessive engine speed will overload the

engine and cause early failure. The engine loses 3% of

its power for every 1,000 feet (305 m) above sea level,

so if your installation is at a higher altitude than normal,

consult the factory.

Chapter 2—Operation Procedures

Performance curves and charts are provided in Appendix C.

The following steps should be performed for the initial

pumping operation:

1. Verify the strainer screen is clean.

2. Rotate the pump by hand.

3. Check V-belt drive or direct drive coupling alignment.

Misalignment will cause accelerated wear of the drive

system, motor bearings and pump.

4. Check motor for proper wiring.

5. Review complete system to make certain the function

of every valve and piece of equipment is clearly

understood. Everyone operating this system must be

properly trained in normal operating procedures and

emergency procedures in event of a malfunction.

6. Close all hose valves.

7. Slowly open the storage tank bottom shut-off valve

(suction line to the pump). Immediately check the

system for leaks.

8. Open any shut-off valves between the bypass valve

and the storage tank.

9. Make a note of all pressure gauge readings, especially

the pressure gauge located at the discharge of the

pump. Start the pump and circulate the liquid through

the bypass system back to the storage tank.

10. Verify the proper pump rotation direction. There is an

arrow cast in the pump case.

11. An ammeter may be used by adjusting the bypass

valve until the ammeter indicates the full load motor

amperage rating shown on the motor nameplate or

maximum rated differential, whichever comes first.

Permit the pump to circulate liquid for half an hour or

more. If the motor overload protection device stops

the motor in this period the bypass valve setting is

too high and should be readjusted until the motor

will run for half an hour. After a satisfactory setting is

achieved, “seal” the valve adjusting stem to prevent

tampering with the adjustment. See IH102 for more

details on the use of the Corken bypass valves.

12. If your pump has an internal relief valve, it must be

set higher than the external bypass setting. The

internal relief valve may be adjusted while the pump

7

Loading...

Loading...