Installation, Operation

& Maintenance Manual

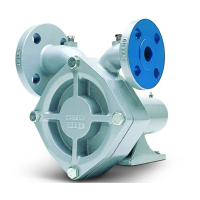

Z-Series Sliding Vane Pumps

Truck and Stationary

Model Z3200 Truck Pump

Model Z2000 Truck Pump

Model Z4200 Truck Pump

Model Z4500 Stationary Pump

Model Z3500 Truck and

Stationary Pump

Solutions beyond products...

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken products

must be made only by experienced, trained and qualied personnel. (3) Maintenance, use and installation of Corken products must comply with

Corken instructions, applicable laws and safety standards (such as NFPA Pamphlet 58 for LP-Gas and ANSI K61.1-1972 for Anhydrous Ammonia).

(4) Transfer of toxic, dangerous, ammable or explosive substances using Corken products is at user’s risk and equipment should be operated

only by qualied personnel according to applicable laws and safety standards.

ORIGINAL INSTRUCTIONS ID105K