Applicable Notices for

ATEX 94/9/EC Conformity

Product Type:

Sliding Vane Pump (Coro-Vane

®

)

Models Covered:

Z/ZH2000, ZX/ZXH2000, Z/ZH3200, Z3500, Z/ZH4200,

and Z4500

Intended Application:

The pump models covered by this manual conform to the

European Union ATEX 94/9/EC Directive for explosive

gas atmospheres and transfer of liqueed gases such as

Liqueed Petroleum Gas, anhydrous ammonia, freons,

etc. Electric motors for these pumps in the assembly must

comply with all applicable requirements for local, federal,

and regional codes and regulations.

Possible Misuse Warning:

The designated pump models must only be installed

in systems designed for its intended use, similar to the

examples presented in this manual.

ATEX Classication:

Group II; Category 2; G; Temperature Class T4 – T5

These products are classied under the ATEX directive

as Equipment – Group II – Category 2 – equipment is

intended for use in areas where explosive atmospheres

caused by gases or vapors (G) may be present. The

surface Temperature Class rating is a range between T4

275°F (135°C) and T5 212°F (100°C).

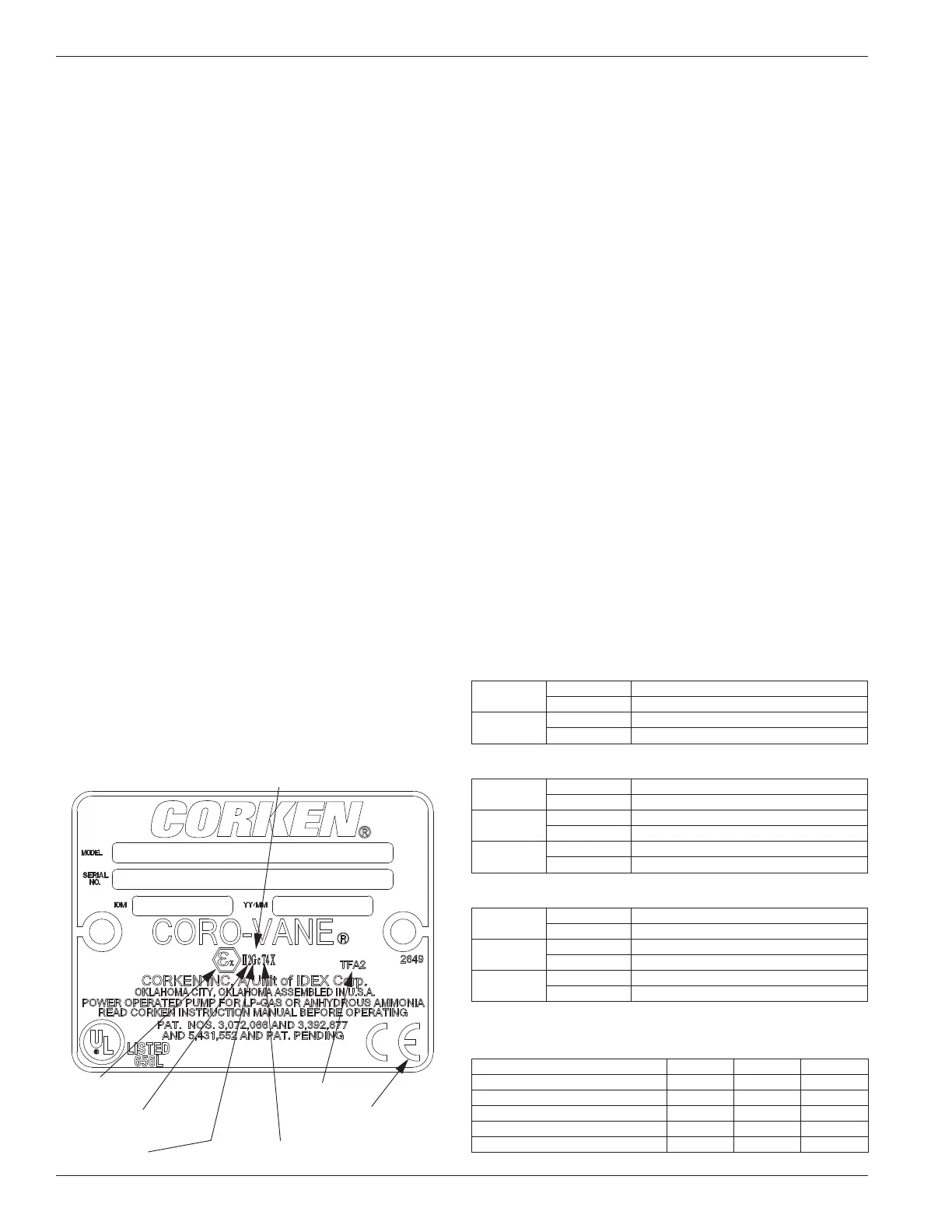

Nameplate:

Explosive gas

atmosphere high level

Maximum surface temperature

T4 275°F (135°C)

ATEX and

machinery directive

File number

Explosive

protection

ATEX directive 94/9/EC marking

Equipment classified as

Group II—Catagory 2

Training Instructions:

Instructions for the safe application and use of this

product are provided in this manual. Read this manual

completely prior to installation and use of this product.

Only qualied and properly trained personnel should be

allowed to install, operate, and maintain this equipment.

Mechanical Ignition Sources:

This equipment may be direct driven through a coupling by an

electric motor or belt driven by an electric motor. Guards for

the drive mechanism in the assembly intended for personal

protection are to be supplied by the customer. The pump

assembly including the drive system must be grounded to

prevent possible electrostatic discharge. Internal parts of the

pump require uid (product being pumped) or damage may

occur. Do not run the pump dry (without liquid in the pump).

The application of liquid level controls in the pump system

is recommended. Preventive Maintenance guidelines are

provided in this manual and are to be followed for the proper

operation and performance of the pump.

Sound Levels:

When properly installed and operated, these pumps do

not exceed 85 dBA noise levels at a distance of one

meter (3.281 ft) from the surface of the pump. This value

is highly dependent upon the installation and may vary

from installation to installation.

Piping Forces and Moments:

Maximum Allowable Pipe Torque

Z/ZH/ZX/ZXH2000

Inlet Size 2 in. (50 mm)

Torque 1,650 in•lbs (186 N•m)

Outlet Size 2 in. (50 mm)

Torque 1,650 in•lbs (186 N•m)

Z/ZH3200 and Z3500

Inlet Size 3 in. (80 mm)

Torque 1,800 in•lbs (203 N•m)

Outlet Size 2 in. (50 mm)

Torque 1,650 in•lbs (186 N•m)

Auxiliary

Inlet

Size 2 in. (50 mm)

Torque 1,650 in•lbs (186 N•m)

Z/ZH4200

Inlet Size 4 in. (100 mm)

Torque 1,900 in•lbs (215 N•m)

Outlet Size 2 in. (50 mm)

Torque 1,650 in•lbs (186 N•m)

Auxiliary

Inlet

Size 2 in. (50 mm)

Torque 1,650 in•lbs (186 N•m)

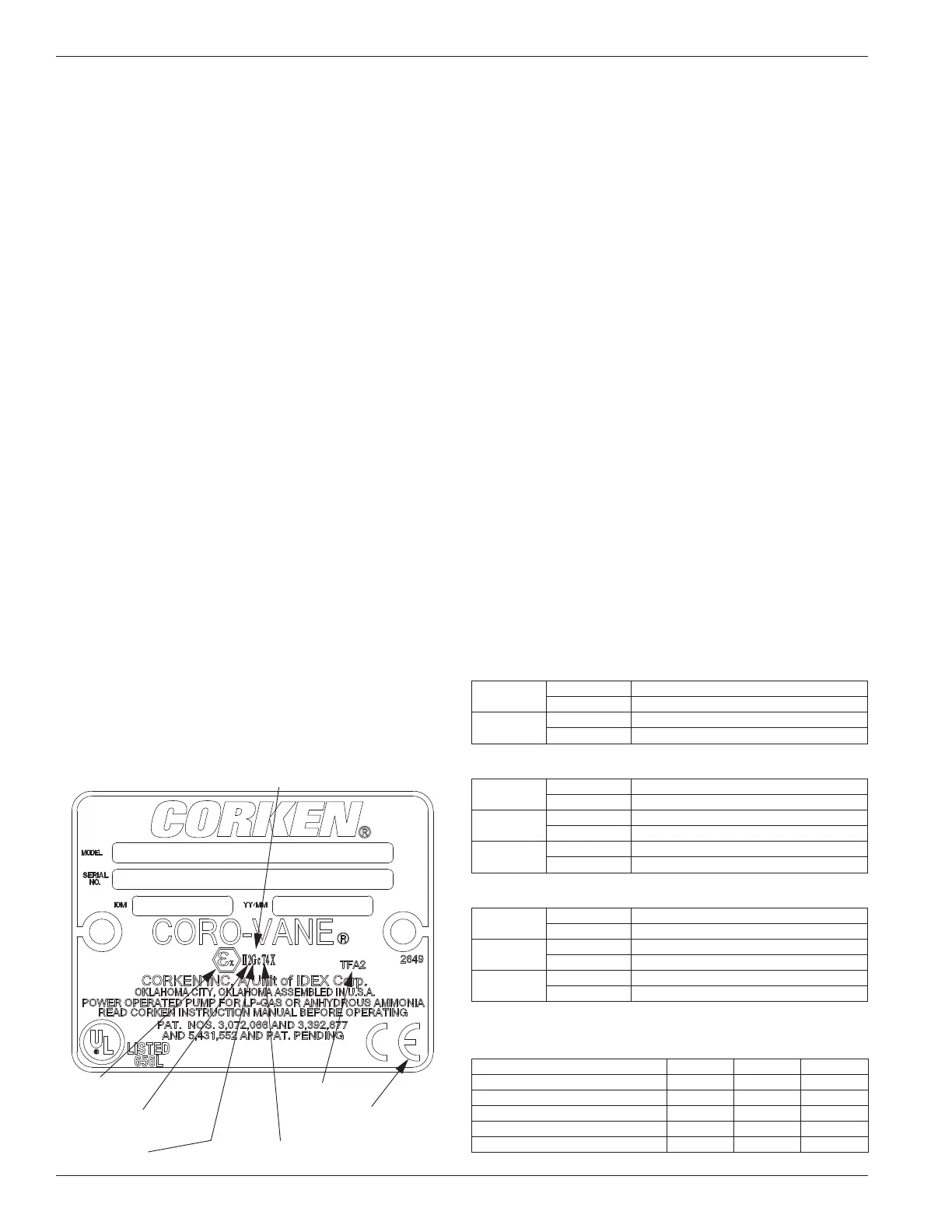

Preventative Maintenance

Pump Maintenance Schedule:

Daily Monthly 3 Months

Lubricate bearings X

Inspect drive couplings X

Clean inlet strainer X

Check for leaks X

Inspect hose and ttings X

4

Loading...

Loading...