1.1 The Outlet Piping Should

Include the Following

1. A liquid lled pressure gauge should be installed in the

pump outlet or near it. A pressure gauge is necessary

to determine the efficiency of your pumping system.

2. A hydrostatic relief valve is required by most state laws

and for your own safety.

3. If a meter with a vapor eliminator is installed, pipe the

eliminator outlet to the top of your tank. Never pipe the

eliminator into the pump inlet piping or into the liquid

part of the system at any point.

4. The meter back-pressure valve may be piped into the

tank top or into the pump inlet piping.

5. The discharge piping should be at least the same size

as the meter.

1.2 The Bypass System

The internal safety relief valve is intended as a safety

device and not as an operational bypass valve. The

external bypass valve should be set at a differential

pressure lower than the internal relief valve and may be

connected to the tank at any convenient point, liquid or

vapor. All Z-Series pumps (except ZX2000, which is set

at 175 psid) are set near 150 psid.

ZH2000 Foot mounted hydraulic drive with NPT

connections

ZX2000 Foot mounted with NPT connections and high

pressure internal relief valve spring (175 psid

rather than the standard 150 psid)

ZHX2000 Foot mounted hydraulic drive with NPT

connections and high pressure internal relief

valve spring (175 psid rather than the standard

150 psid)

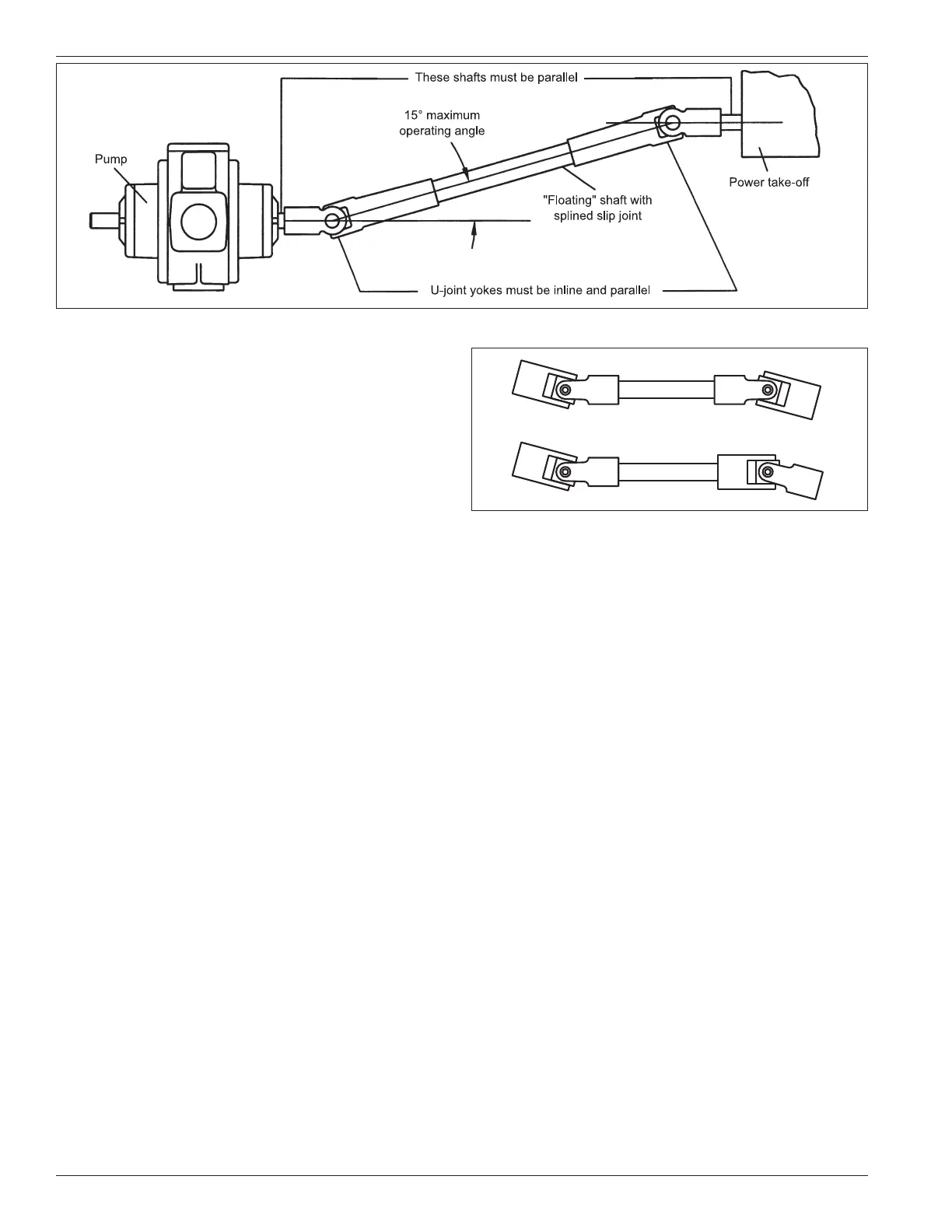

1.3 Power Take-off (PTO)

Drive Systems

Proper pump operation and long life are directly dependent

upon a good drive system. Many truck pumps utilize a

power train consisting of shafts and universal joints from

a power take-off shaft on the truck engine to the pump.

There are several basic principles that should be followed

in laying out a PTO drive. These principles should not be

violated. Following them will produce a workable power train

that results in long pump life and reduced drive wear.

First, the driver shaft and the driven shaft must be parallel

to one another within plus or minus one degree. Improper

alignment will cause jerking and back and forth “whip” to the

pump shaft, thereby imparting a surging pulsation to the liquid

ow, which results in noise, vibration, and abnormal wear.

Second, the angle of the “oating” shaft should be within

the limits for the particular equipment being used (usually

a maximum of 15° at pump speeds up to 800 RPM). To

ensure that shaft expansion or contraction does not distort

the drive system, a splined slip joint should be placed

between the two universal joints. The drive shaft should

be of the “splined” or slip type to permit the shaft to adjust

for PTO movement and twisting of the truck frame. A xed

drive shaft transmits the forces directly to the pump and

PTO which will shorten the life of both considerably.

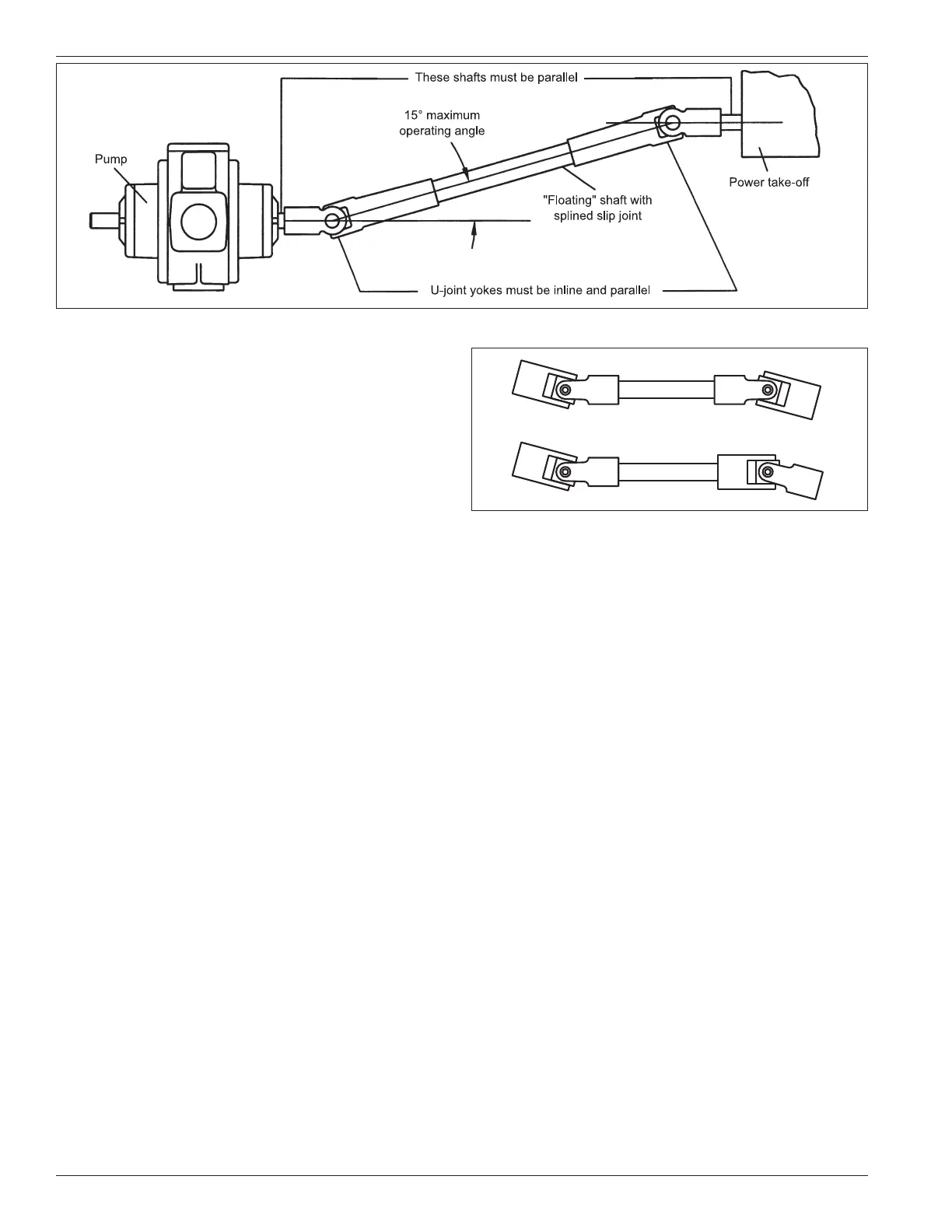

Third, the yokes of the drive shaft universal joints must be

in a parallel position. Figures one and two illustrate the

proper arrangement.

Figure 1.1: Shaft Alignment

Correct assembly

Incorrect assembly

Figure 1.2: Universal Joint Alignment

6

Loading...

Loading...