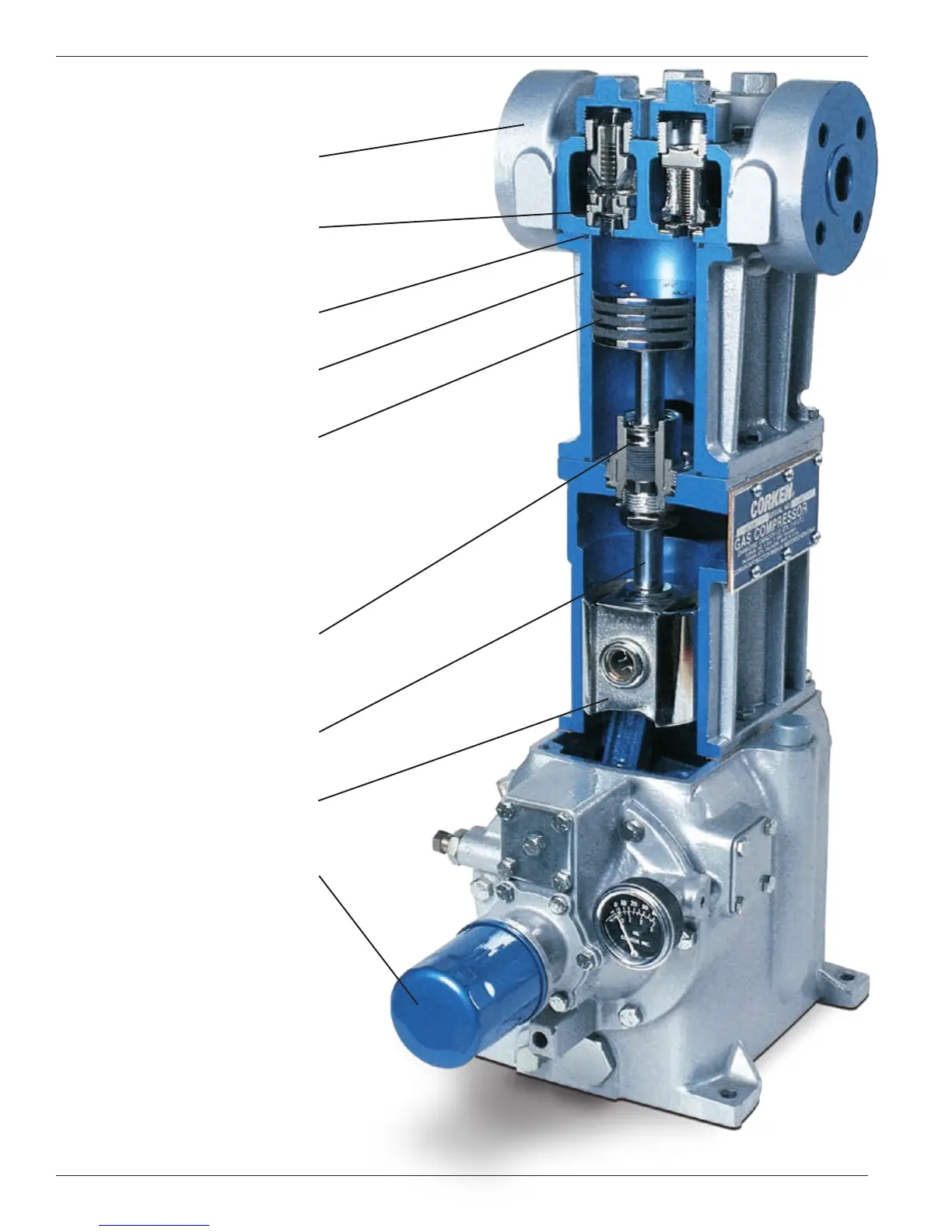

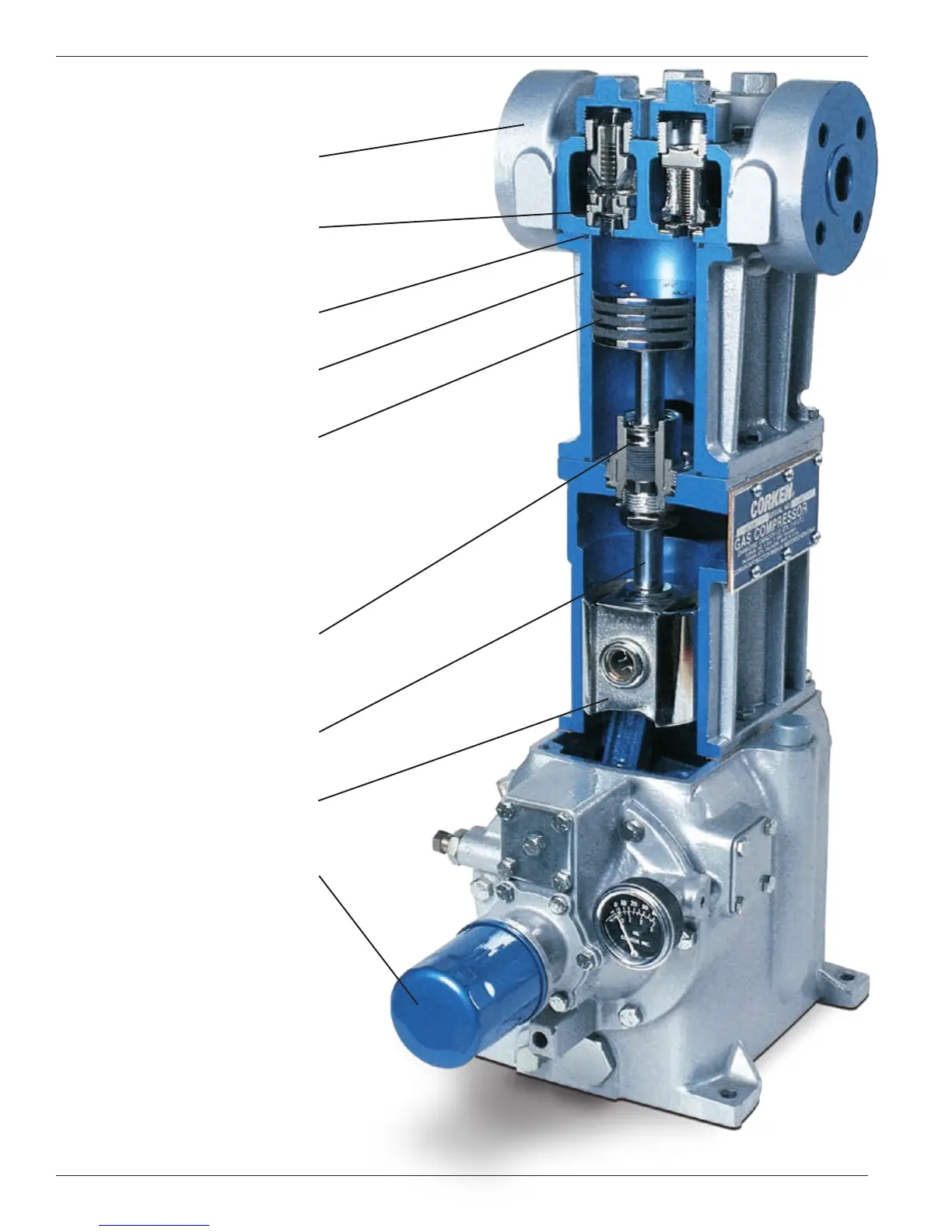

Connections:

Available in threaded NPT or Class 300

RF flanges.

High-efficiency valves:

Valves are quiet and highly durable. Special

suction valves tolerating small amounts of

condensate are available.

O-ring seals:

Easy to install O-ring seals head and cylinder.

Ductile iron construction:

Cylinder and head are made of ductile iron

for maximum thermal shock endurance.

Self-lubricating PTFE piston rings:

State-of-the-art piston ring designs to

provide the most cost-effective operation

of compressors for non-lube service. The

step-cut design provides higher efficiencies

during the entire life of the piston ring.

Positively locked piston:

Simple piston design allows end clearance

to be precisely set to provide maximum

efficiency and long life.

Piston rod seals:

Seals constructed of PTFE incorporating

special fillers to maximize leakage control.

Spring loaded seal design self adjusts to

compensate for normal wear.

Nitrotec

®1

coated piston rods:

Impregnated nitride coating provides

superior corrosion and wear resistance.

Cast-iron crosshead:

Durable cast-iron crossheads provide

superior resistance to corrosion and galling.

Pressure-lubricated crankcase with filter:

Self-reversing oil pump ensures proper

lubrication regardless of directional rotation to

main and connecting rod bearings. Standard

10-micron filter ensures long-lasting bearing

life (not available on Model 91).

1

Registered trademark of TTI Group Ltd.

Chapter 1—Introduction

Construction Details—Model F291 Compressor

4

Loading...

Loading...