CH1500, CH2000 & CH3000 Chiller Operator’s & Installation Manual

© 2010-2014, Cornelius Inc. - 5 - Publication Number: 621055837OPR

PLUMBING

Follow standard plumbing practices and local codes in making water connections. The chiller inlet and outlet

connections are 3/4 inch. Flexible hoses and fittings are recommended for plumbing the system. A No. 20 mesh

strainer should be installed on the chiller inlet to prevent foreign particles from entering the system and should be

cleaned monthly (field installation, not provided with chiller). Lines should be routed with as few bends as possible.

Prevent lines from running near radiators, hot water pipes, etc. Any lengths of tubing that are exposed to high ambient

temperatures should be insulated to prevent condensation and/or significant liquid heat loss.

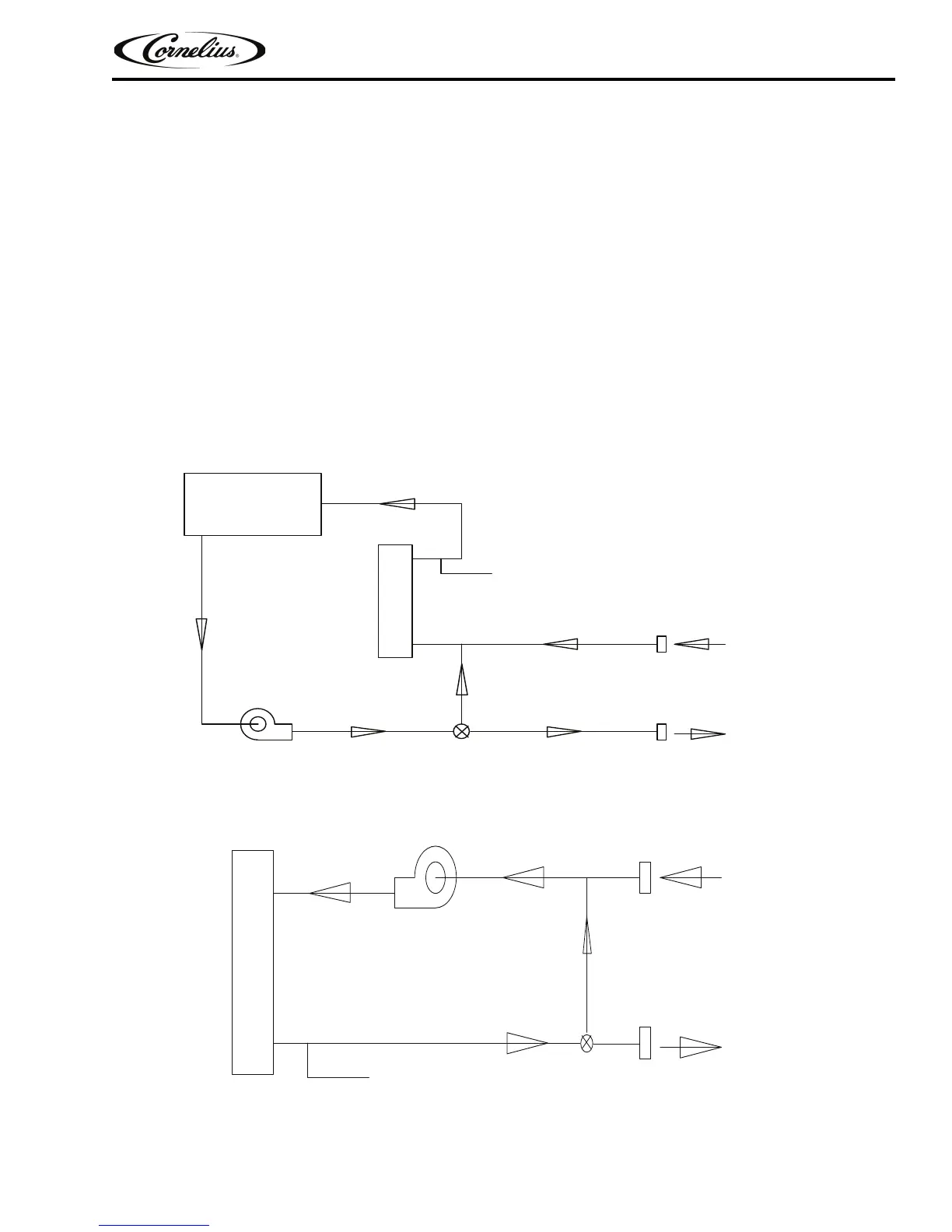

Chiller with Reservoir

The reservoir can be filled by removing the water fill cap located on the upper rear of the Chiller (See Fluid

Recommendations). After ensuring that the drain valve is closed, fill the reservoir via the full port with clean water until

the water level sight glass on the front of the unit indicates “FULL” the fill cap should then be reinstalled before

operation begins.

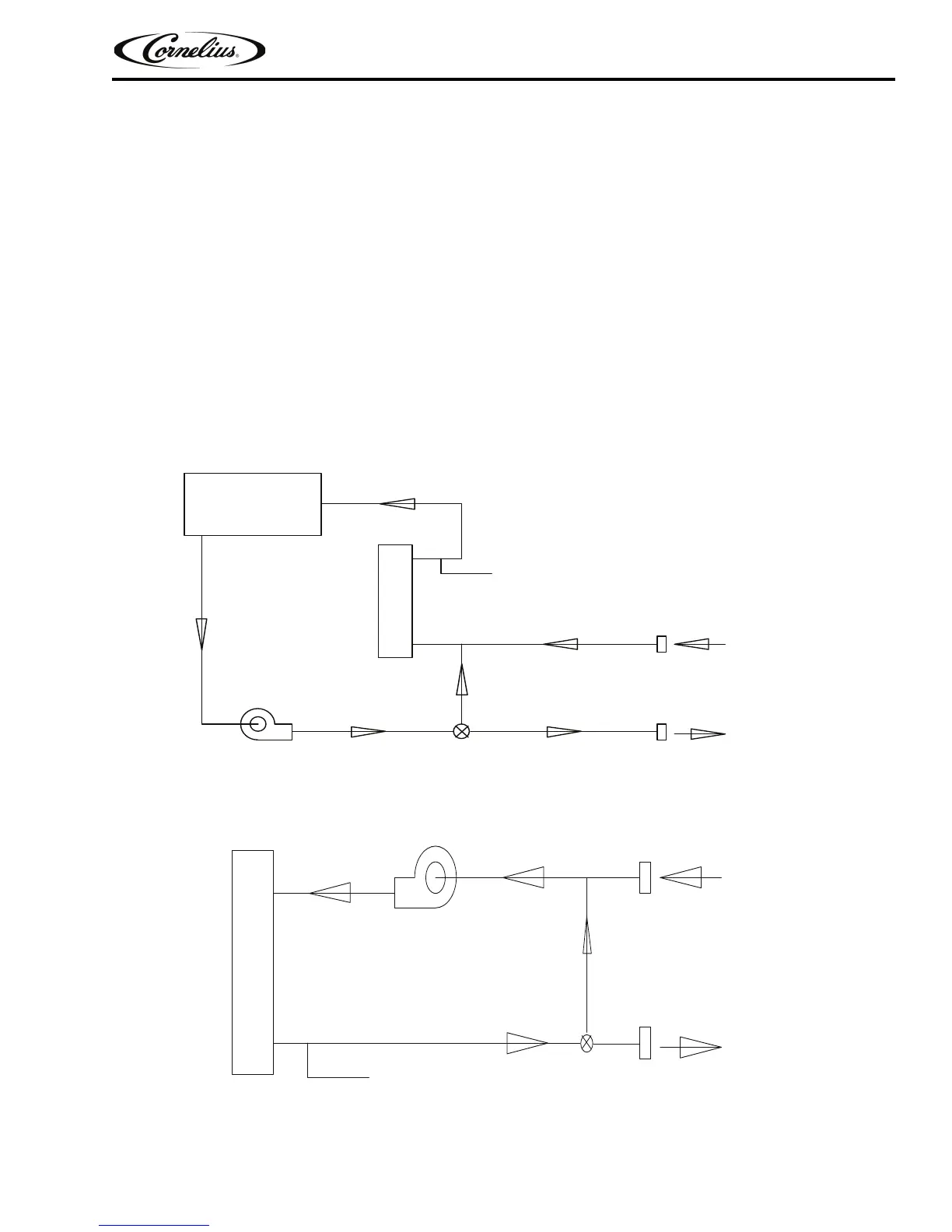

Chiller without Reservoir

The chiller and system piping should be filled with clean water or proper fluid ensuring that all air is purged from the

system.

RESERVOIR

LOW TEMP. CONTROL

FROM PROCESS

CHILLER INLET

EVAPORATOR

EVLAV SSAPYBPMUP

CHILLER OUTLET

TO PROCESS

Figure 2. Chiller Plumbing Schematic with Pump and Tank (Standard)

Figure 3. Chiller Plumbing Schematic, no Tank (Option)

CHILLER INLET

FROM PROCESS

EVAPORATOR

LOW TEMP. CONTROL

CHILLER OUTLET

TO PROCESS

BYPASS VALVE

Loading...

Loading...