UF-1 and UFB-1 Valves Training Manuai

Publication Number: 315222001OPR - 5 - © 2023, Marmon Foodservice Technologies Inc.

SYSTEM DETAILS

1. WATER

1.1 Water Quality

Water quality issues have an affect on dispensing valves. Chloramine, a combination of chlorine and ammonia is

responsible for some degradation of rubber components. Chloramine is used in many U. S. water supplies. Its

affects can be minimized by installing and maintaining a water filtration system.

Ultra pure water affects the sensitivity of the Optifill™ valve.

Because ultra pure water has less mineral content, it

reduces the conductivity of the water keeping the circuit open and overfilling the beverage container.

1.2 Water Flow

The size of the orifice in the piston varies depending on whether the piston is used forsyrup or water, and whether

it is high flow or ultra flow valve.

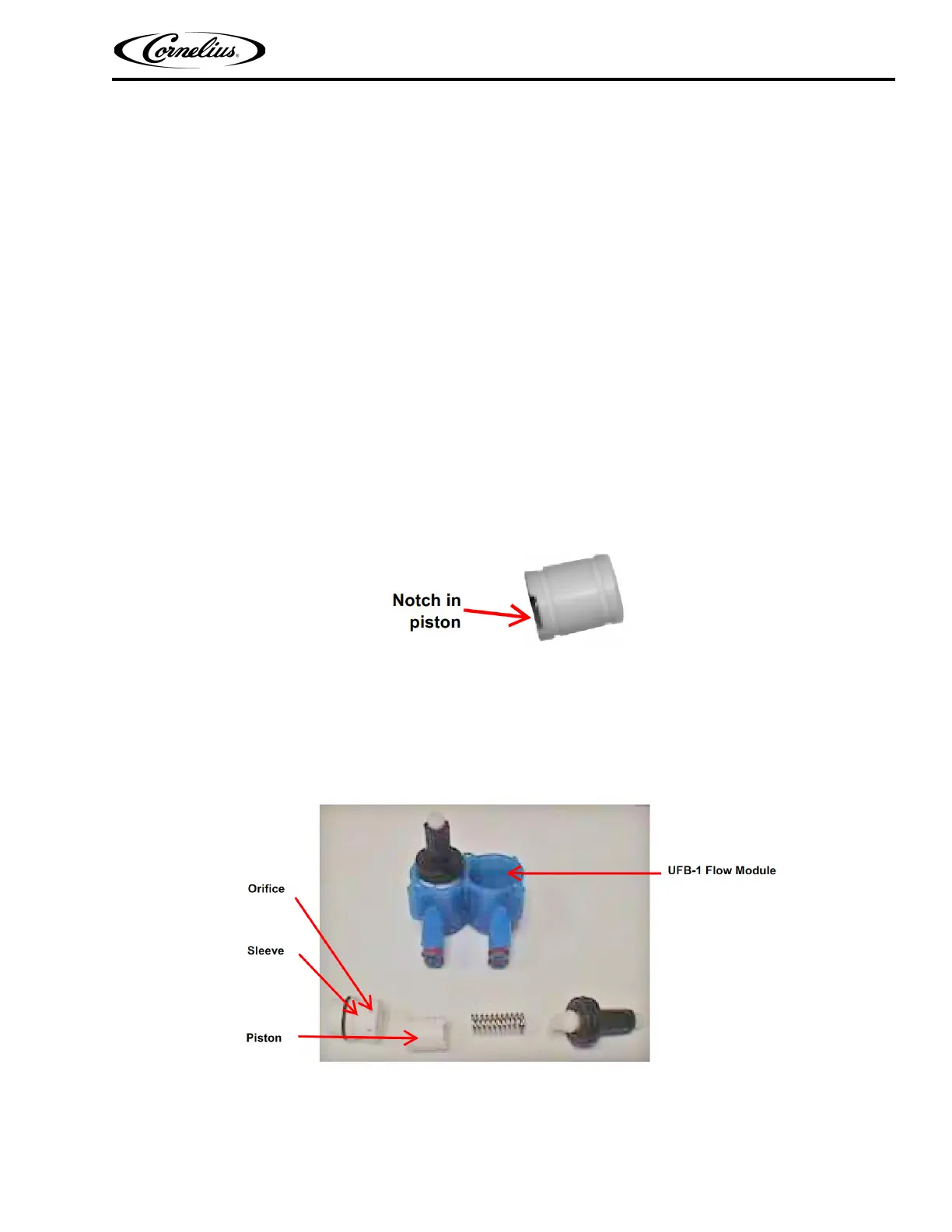

Note: T

he notched water piston on the Ultra Flow and UFB-1 valve. results in at least one orifice in the sleeve

always open. This eliminates pulsating and smooths water flow at higher flow rates.

Figure 5

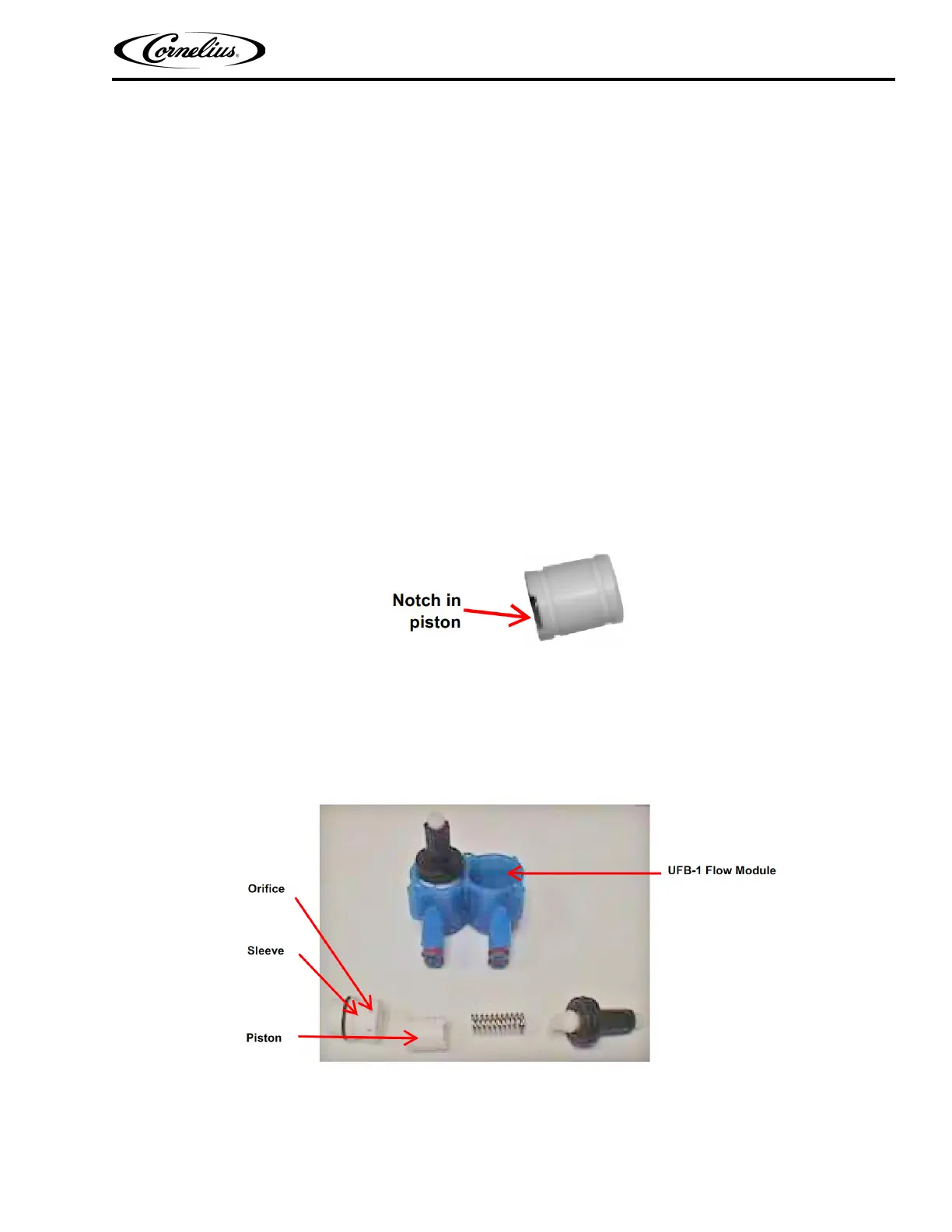

In operation the liquid flows through the knife–edged orifice in the bottom of the piston and then out the orifices

in the sleeve. The outlet orifice size in the sleeve is regulated by the position of the piston. In the illustration, the

piston is restricting approximately 1/2 of the outlet orifices.

Figure 6

Loading...

Loading...