10

ENGLISH

Maintenance

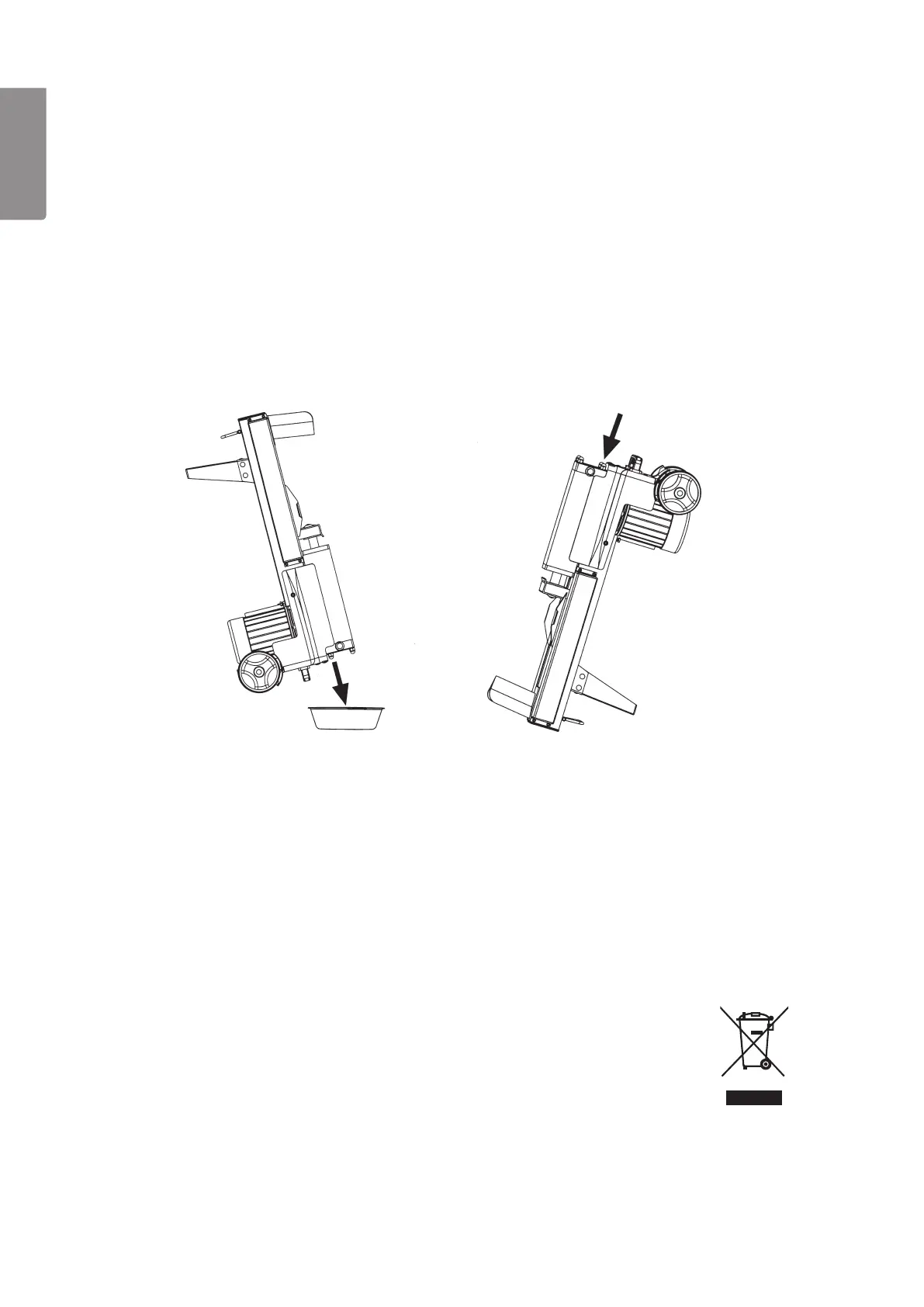

Changing the hydraulic oil

The hydraulic oil has to be changed at regular intervals (approx. 150 hrs) according to thefollowing:

1. Ensure that thepressure plate is in its original position and disconnect thepower cable.

2. Unscrew theoil plug (16).

3. Lift thepull handle and tip thelog splitter over acollecting tray which holds at least 4 litres and wait until all

theoil has run out.

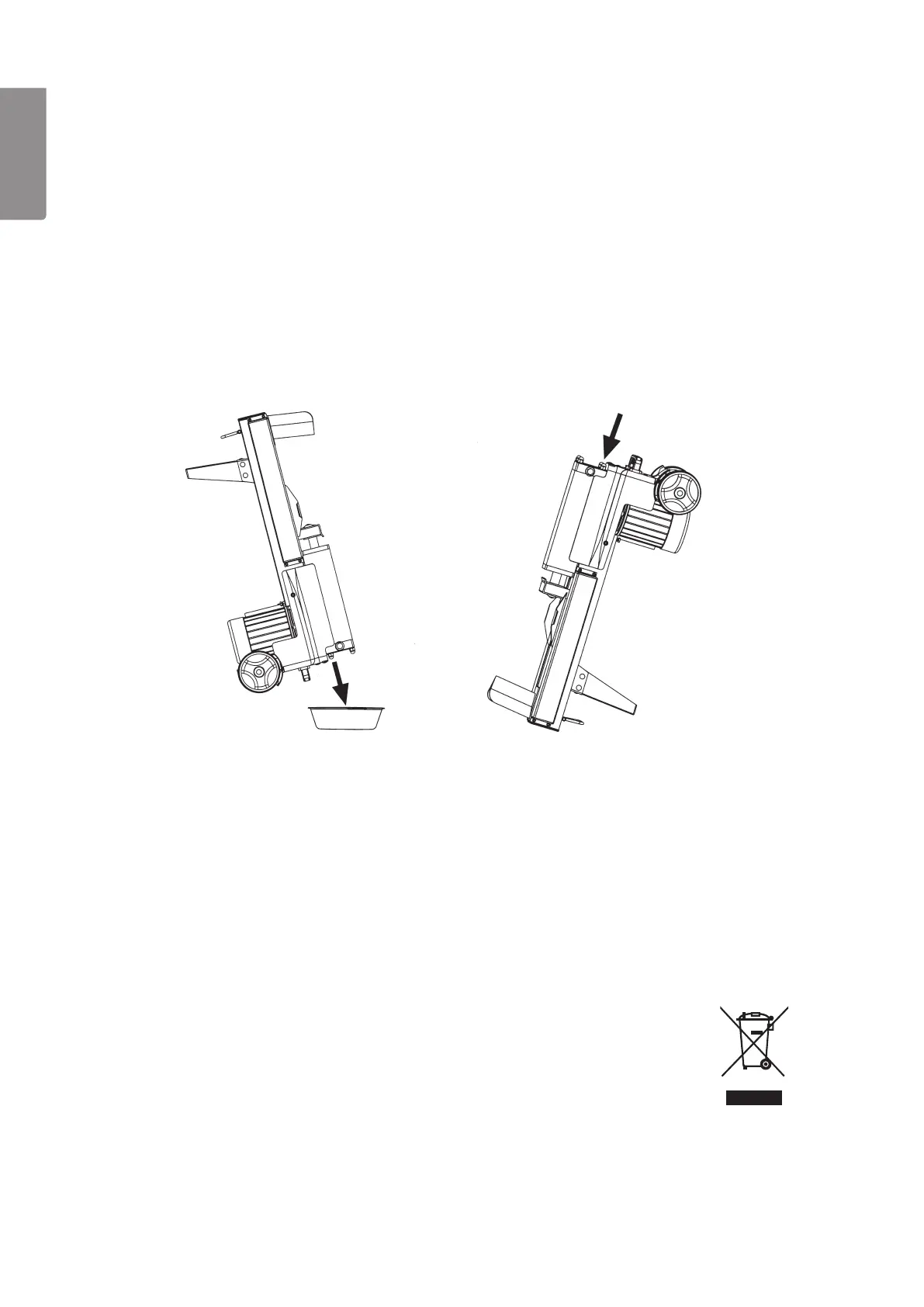

4. Tip thelog splitter so that themotor side is up and fill using good quality hydraulic oil (approx. 2.4 litres)

5. Wipe thedipstick and place it in thetank when thelog splitter is in ahorizontal position. Pull it back out and

take areading. The oil level should be between thetwo markings on thedipstick.

6. Clean theoil plug and screw it back properly so that theoil does not leak out.

7. Check theoil level regularly and when necessary, top it up.

Sharpening the splitter

Keep thesplitter sharp by filing off theburrs of thecutting edge regularly using afinely serrated metal file.

Other Maintenance

• Always remove theplug before commencing maintenance.

• Ensure that all power cables, plugs and switches are undamaged and in good working order.

• Clean all of thesurfaces on thelog splitter using abrush and dry cloths.

• Store themachine in adry, clean and non-corrosive environment out of reach for children. Ensure that

thestorage temperature does not fall below −25° C.

• Clean thereturn springs under thework bench with awooden wedge or use pressurized air.

Disposal

Follow local ordinances when disposing of this product. If you are unsure about how

to dispose of this product contact your municipality.

Loading...

Loading...