11

ENGLISH

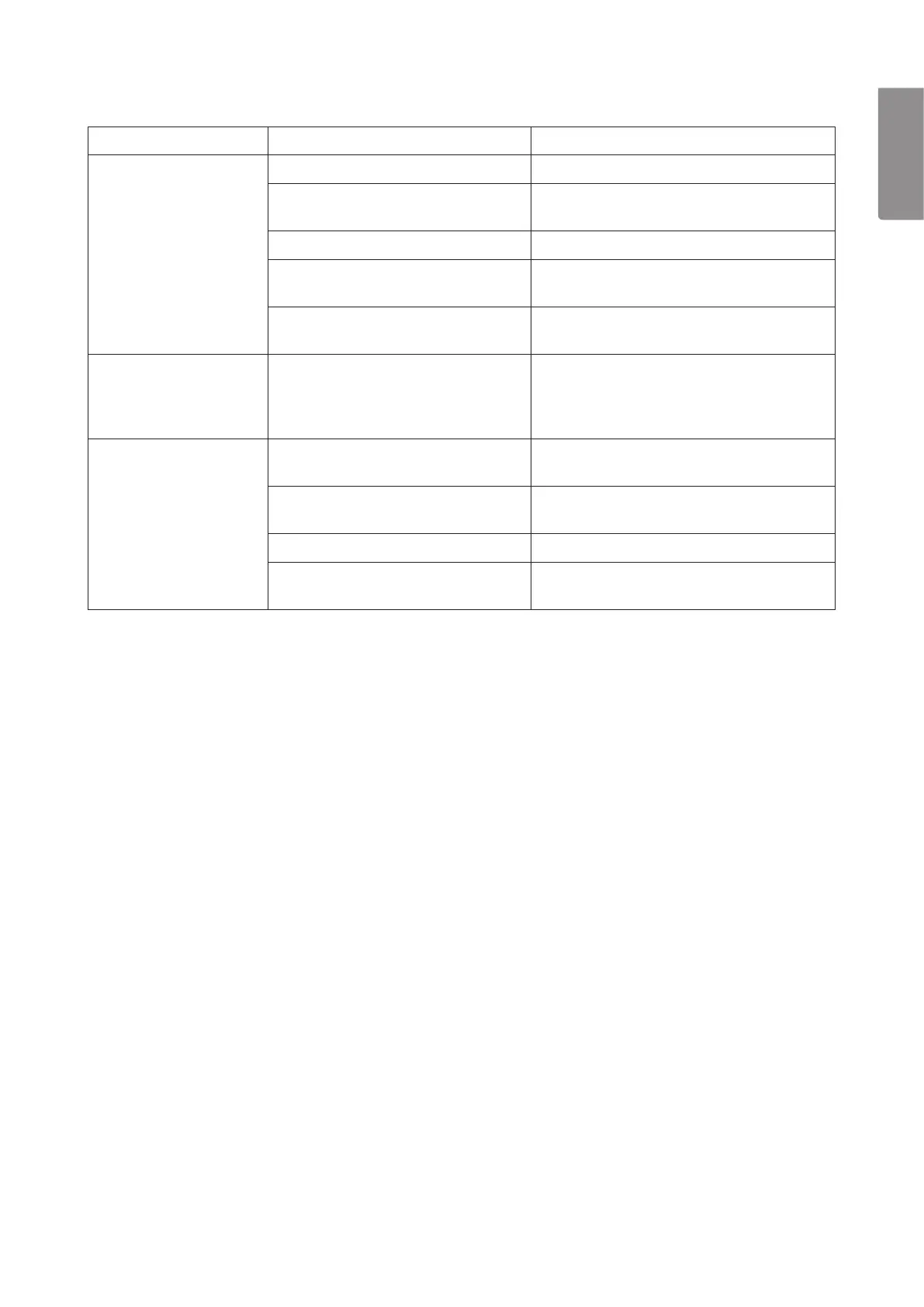

Troubleshooting

Problem Possible cause Suitable measure

Unsuccessfull splitting. The log is wrongly placed. Turn around or rotate thelog.

The hardness or diameter of thelog

is too great.

Try decreasing thediameter or length

before splitting.

The splitter is blunt or damaged. Sharpen thesplitter (see Maintenance).

Oil leakage. Find theleakage and let aqualified

technician repair it. Top up theoil.

Pressure regulator wrongly adjusted. Let aqualified technician with access to

testing equipment repair it.

The pressure plate

moves abruptly with

ajarring sound and

strong vibrations.

Oil pressure too low - air in

the system.

Check thelevel and if required top

up theoil or repair leakage.

Oil leakage around

thepiston or other

component.

Air pockets in thehydraulic system

during operation.

Loosen thebleeding screw 3–4 revolutions

before starting operation.

The air screw has not been tightened

before transport.

Tighten thebleeding screw before transport.

The oil plug is not tightened sufficiently. Tighten theoil plug.

The hydraulic valve and/or packing

are worn out.

Contact retailer.

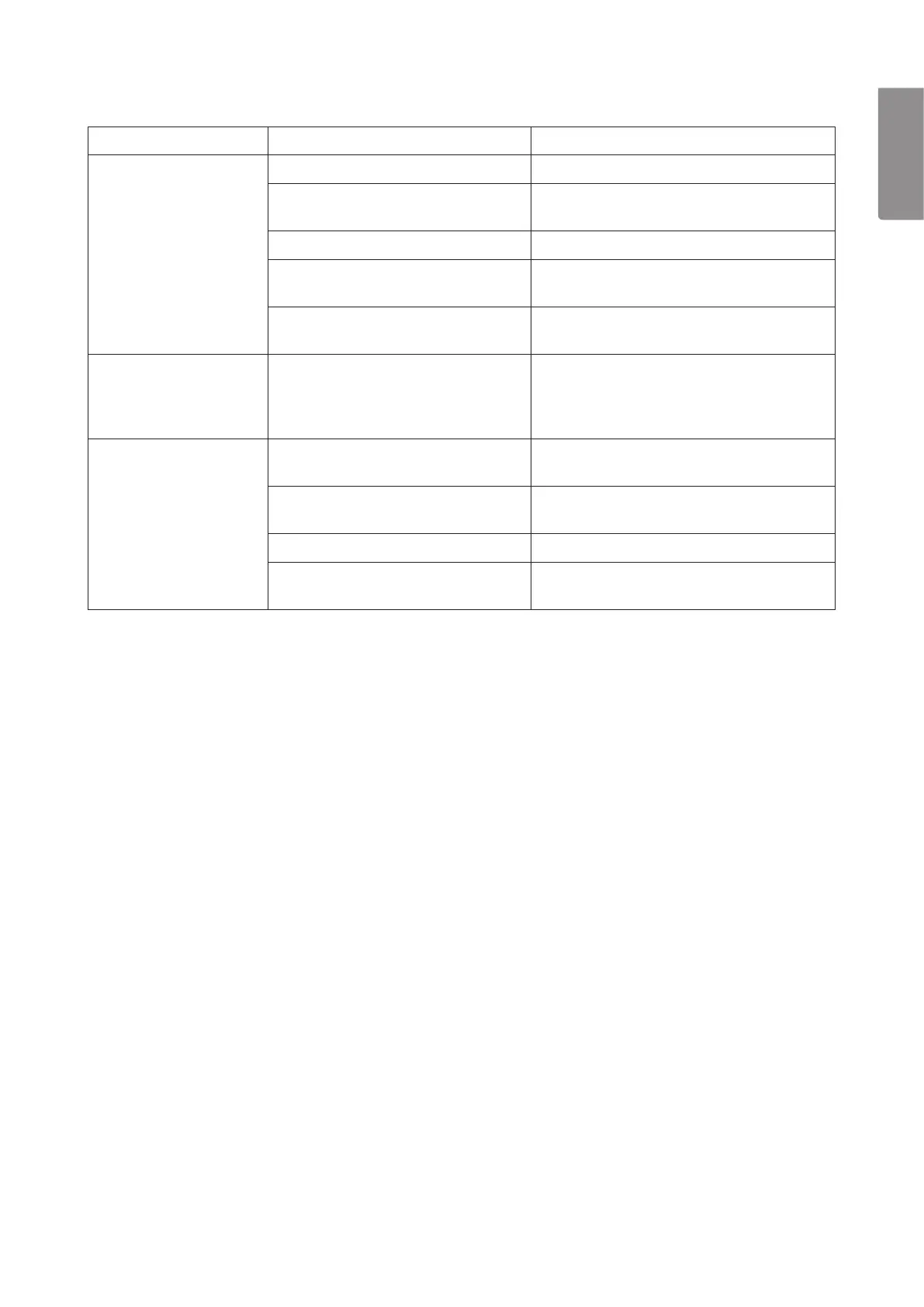

Technical specification

Model LS5T-52

Motor 230 V AC 50Hz

Power 1500 W

Enclosure class IP54

Splitting capacity* Ø 5–25 cm, length 52 cm

Recommended working temperature +5° C to +40° C

Splitting force 5 tonnes

Hydraulic pressure 20 Mpa

Hydraulic oil capacity 2.4 l

Dimensions Length 122 cm

Width 25 cm

Height 48 cm

Weight 50 kg

*The stated values are for guidance. The capacity depends on thehardness of thepiece of wood,

diameter and theamount of knots

Loading...

Loading...