DIRECT VENT GRAVITY GAS WALL HEATER 13

CHECKING THE GAS PIPING

Test all piping for leaks. When checking gas piping to the furnace

with gas pressure at less than 1/2 PSI, shut o manual gas

valve to the furnace. If the gas piping is to be checked with the

pressure at or above 1/2 PSI, the furnace and manual shuto

valve must be disconnected during testing. Apply a soap solution

(or a liquid detergent) to each joint. Bubbles forming indicate a

leak. Correct even the slightest leak at once.

WARNING: Danger of property damage, bodily

injury or death. Never use a match or open ame to test for

leaks. Never exceed specied pressures for testing. Higher

pressures may damage the gas valve and cause over ring

which may result in combustion chamber failure. Liqueed

petroleum gas (PRPN GAS) is heavier than air and it will

settle in any low area, including open depressions and it

will remain there unless area is ventilated. Never attempt

start-up of the unit before thoroughly ventilating the area and

smelling near the oor for gas odor.

When an existing category I heater is removed or replaced, the

original venting system may no longer be sized to properly vent

the attached appliances

All installations in the State of Massachusetts must use

the following requirements when installing, maintaining or

operating direct-vent propane or natural gas-red space heaters.

For direct-vent appliances, mechanical-vent heating appliances

or domestic hot water equipment, where the bottom of the vent

terminal and the air intake is installed below four feet above

grade the following requirements must be satised:

1. If there is not one already present, on each oor level

where there are bedroom(s), a carbon monoxide

detector and alarm shall be placed in the living area

outside the bedroom(s). The carbon monoxide detector

shall comply with NFPA 720 (2005 Edition).

2. A carbon monoxide detector shall be located in the

room that houses the appliance or equipment

and shall:

a. Be powered by the same electrical circuit as the

appliance or equipment such that only one service

switch services both the appliance and the carbon

monoxide detector.

b. Have battery back-up power;

c. Meet ANSI/UL 2034 Standards and comply with NFPA

720 (2005 Edition); and

d. Have been approved and listed by a Nationally

Recognized Testing Laboratory as recognized under

527 CMR.

INSTALLATIONS IN THE STATE

OF MASSACHUSETTS

A CARBON MONOXIDE DETECTOR SHALL:

a. Be located in the room that houses the appliance

or equipment;

b. Be either hard-wired or battery powered or both; and

c. Shall comply with NFPA 720 (2005 Edition).

3. A product-approved vent terminal must be used, and if

applicable, a product-approved air intake must be

used. Installation shall be in strict compliance with the

manufacturer’s instructions. A copy of the installation

instructions shall remain with the appliance or

equipment at the completion of the installation.

4. A metal or plastic identication plate shall be mounted

at the exterior of the building, four feet directly above

the location of vent terminal. The plate shall be of

sucient size to be easily read from a distance of eight

feet away, and read “Gas Vent Directly Below”.

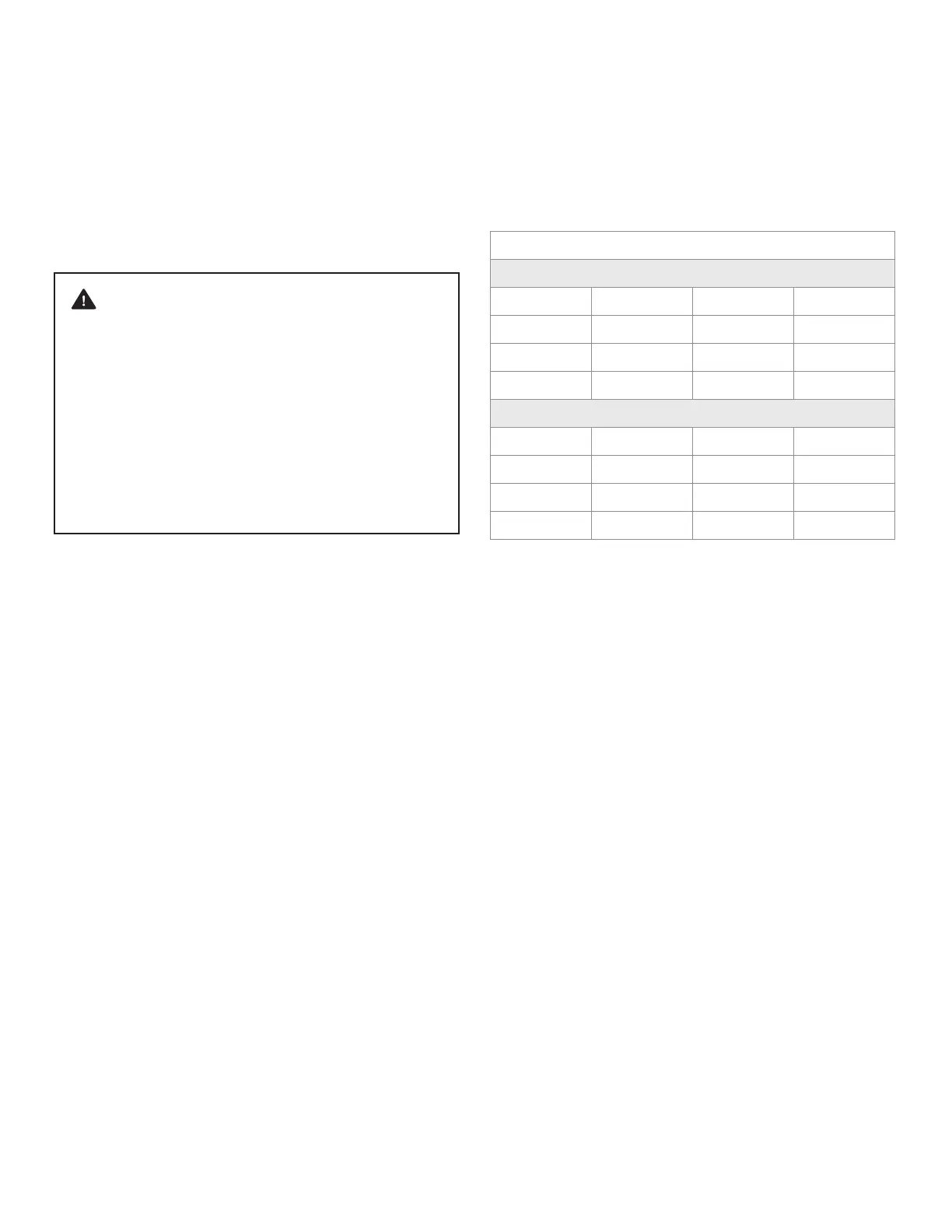

FIGURE 14

GAS PIPE SIZES

NATURAL GAS PIPE CAPACITY - BTU/hr. (includes ttings) PIPE SIZE

LENGTH OF PIPE - FT.

1/2" 3/4" 1"

20 92,000 190,000 350,000

40 63,000 130,000 245,000

60 50,000 105,000 195,000

PROPANE GAS PIPE CAPACITY - BTU/hr. (includes ttings) PIPE SIZE

LENGTH OF PIPE - FT.

1/2" 3/4" 1"

20 189,000 393,000 732,000

40 129,000 267,000 504,000

60 103,000 217,000 409,000

Loading...

Loading...