ASSEMBLY INSTRUCTIONS

To avoidinjury, do not connectthis scrollsaw to'thepower

sourceuntilitis completelyassembledand adjusted, and you

haveread and understoodthisinstruction manual.

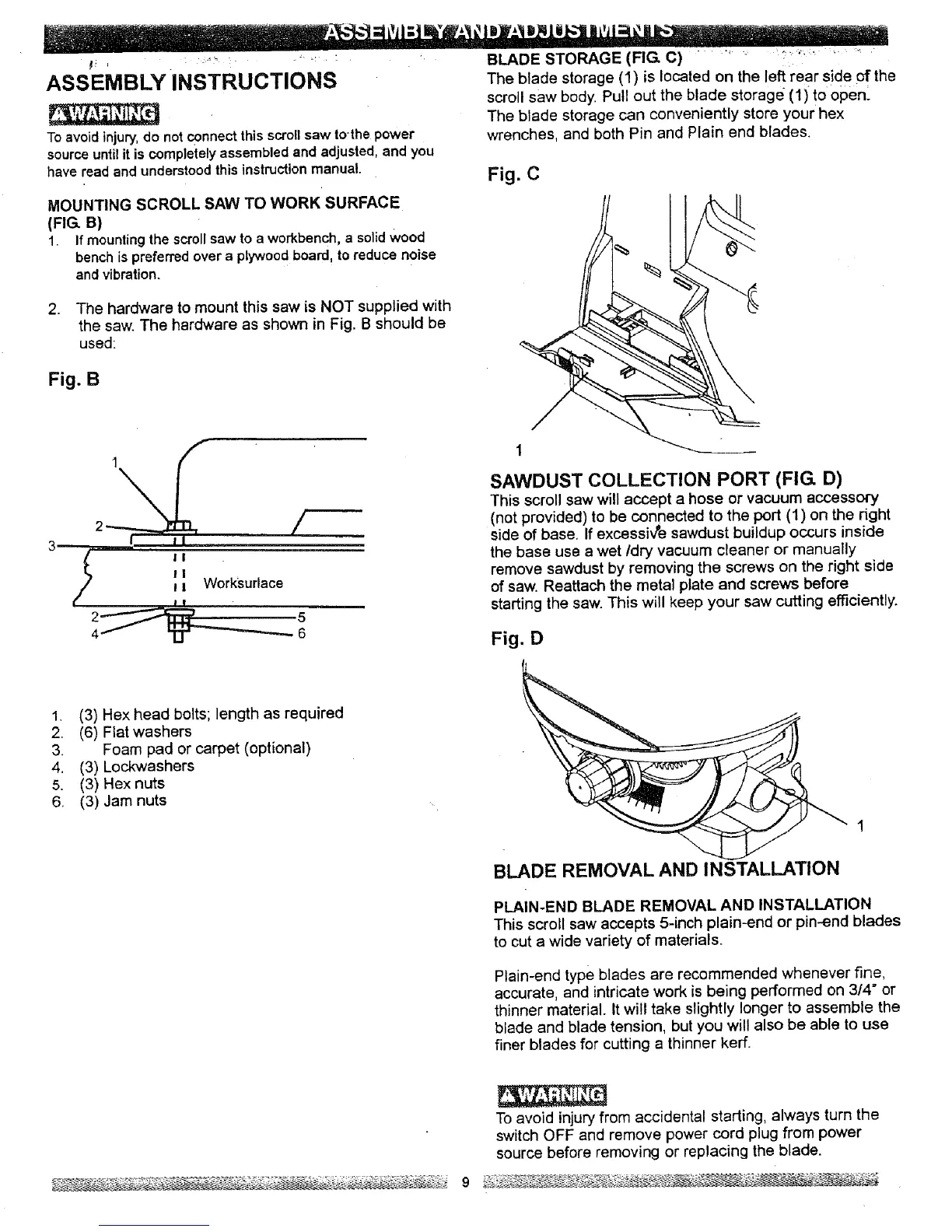

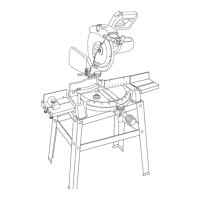

MOUNTING SCROLL SAW TO WORK SURFACE

(FIG. B)

1. If mounting the scroll saw to a workbench, a solid wood

bench is preferred over a plywood board, to reduce noise

and vibration.

2. The hardware to mount this saw is NOT supplied with

the saw. The hardware as shown in Fig. B should be

used:

Fig. B

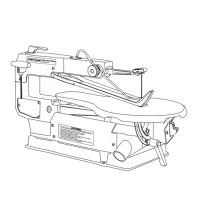

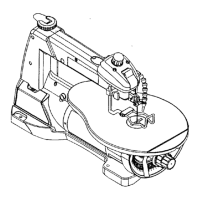

BLADE STORAGE (FIG, C) " ' - : ........ "

The blade storage (1) is located on the left rear s;de of the

scroll saw body. Pull out the blade storage (1) to open.

The blade storage can conveniently store your hex

wrenches, and both Pin and Plain end blades.

Fig. C

_ II

/( "

II

I ! Worksurlace

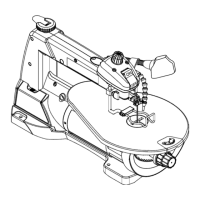

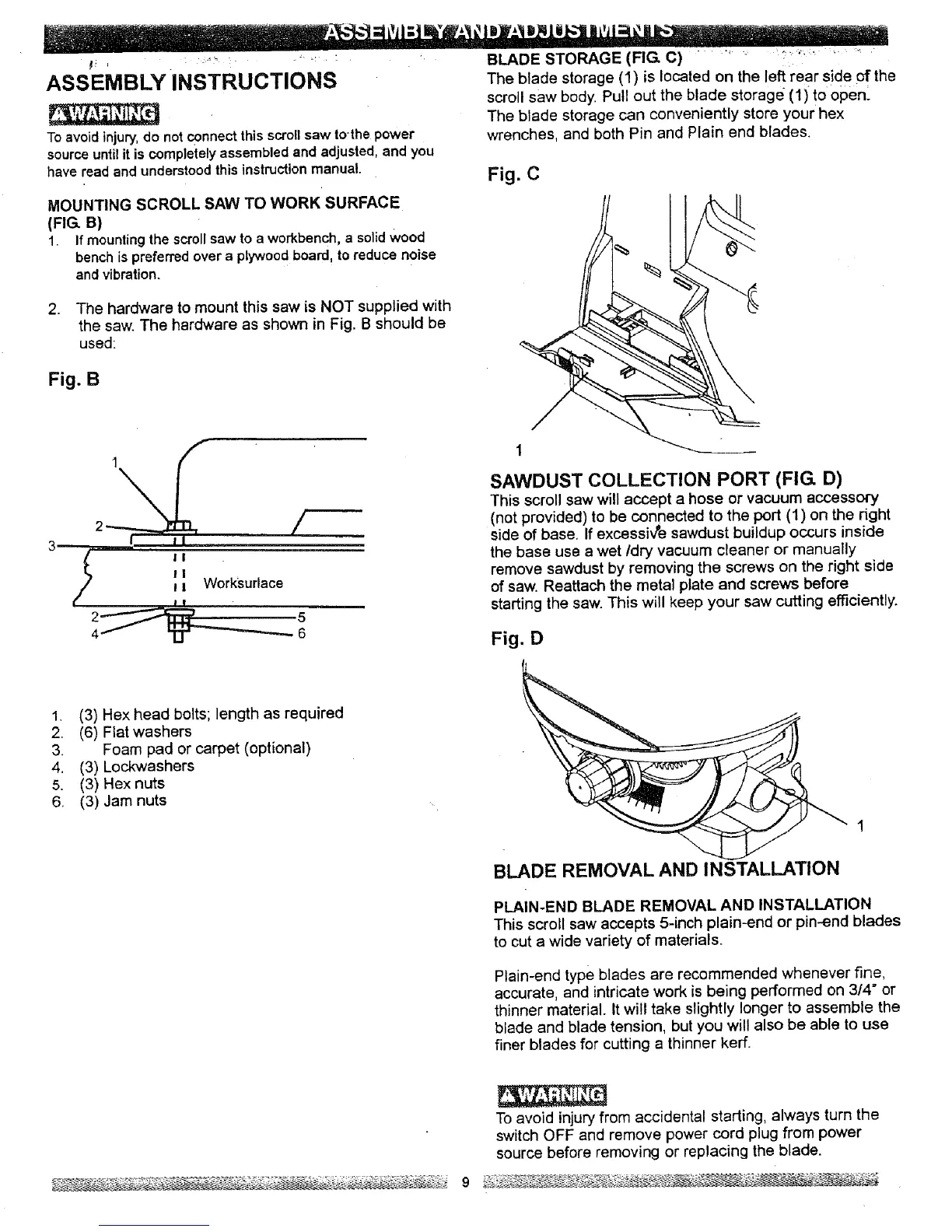

SAWDUST COLLECTION PORT (FIG. D)

This scroll saw will accept a hose or vacuum accessory

(not provided) to be connected to the port (1) on the right

side of base. If excassiv*e sawdust buildup occurs inside

the base use a wet/dry vacuum cleaner or manually

remove sawdust by removing the screws on the right side

of saw. Reattach the metal plate and screws before

starting the saw. This will keep your saw cutting efficiently.

Fig. D

1, (3) Hex head bolts; length as required

2. (6) Flat washers

3, Foam pad or carpet (optional)

4. (3) Lockwashers

5. (3) Hex nuts

6, (3) Jam nuts

BLADE REMOVAL AND INSTALLATION

PLAIN-END BLADE REMOVAL AND INSTALLATION

This scroll saw accepts 5-inch plain-end or pin-end blades

to cut a wide variety of materials.

Plain-end type blades are recommended whenever fine,

accurate, and intricate work is being performed on 314" or

thinner material. It wi!l take slightly longer to assemble the

blade and blade tension, but you will also be able to use

finer blades for cutting a thinner kerf.

Toavoid injury from accidental starting, always turn the

switch OFF and remove power cord plug from power

source before removing or replacing the blade.

Loading...

Loading...