Do you have a question about the Craftsman 315.212040 and is the answer not in the manual?

Details the warranty coverage and terms for the product.

Explains the concept of double insulation for electrical safety in power tools.

Details the required power supply specifications and connection procedures for the tool.

Provides guidance on selecting and using appropriate extension cords for the tool.

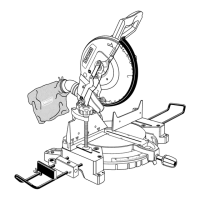

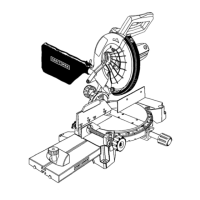

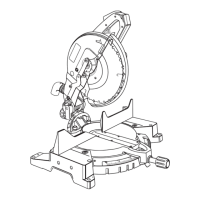

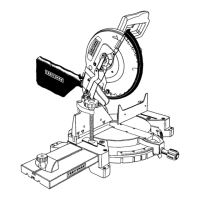

Lists key technical specifications of the compound miter saw, including blade size and motor power.

Encourages familiarization with all operating features and safety requirements before use.

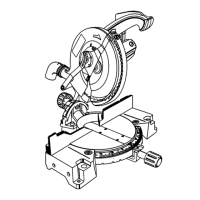

Covers the carrying handle, spindle lock button, trigger lock, and miter lock handle for secure operation and transport.

Details positive stops on the miter table and the bevel lock knob for angle adjustments.

Describes the self-retracting lower blade guard, fence, and mounting holes for secure operation.

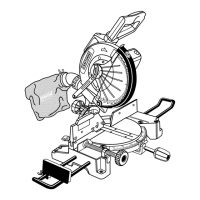

Guide for attaching the miter lock handle and dust guide/bag for secure operation and dust management.

Details how to install the work clamp and the step-by-step procedure for safely installing the saw blade.

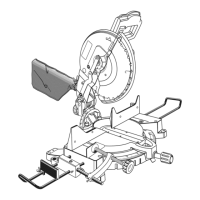

Procedure for aligning the miter table precisely with the saw's fence for accurate cuts.

How to create a blade slot in the throat plate for full angle cutting capability.

Steps to ensure the saw blade is perfectly perpendicular to the fence for precise cuts.

Procedure for ensuring the saw blade is perfectly square to the miter table for accurate cuts.

Lists intended uses and explains how to perform straight and miter crosscuts across the grain.

Detailed steps for executing crosscuts, including setting angles and safety precautions.

Introduces how to make cuts with the blade angled relative to the workpiece.

Step-by-step guide for setting bevel angles and making precise angled cuts.

Explains how to perform cuts using both miter and bevel angles simultaneously.

Guidance on providing adequate support for long materials during cutting operations.

A chart providing recommended miter and bevel settings for various cuts.

Instructions for accurately cutting crown molding using compound miter techniques.

Method for positioning crown molding flat on the table for precise cuts.

Advice on cutting warped wood to prevent blade binding and kickback.

Techniques for securely clamping wide boards for safe cutting.

How to adjust the saw arm's bevel pivot for smooth and accurate angle changes.

How to set the depth stop to control the blade's cutting depth for various materials.

Further details on adjusting the depth stop, including clearance checks.

Guidelines for general cleaning, material handling, and lubrication requirements.

Instructions for checking and replacing motor brushes for continued tool performance.

| Model Number | 315.212040 |

|---|---|

| Type | Circular Saw |

| Blade Size | 7-1/4 inches |

| Blade Diameter | 7-1/4 inches |

| Amperage | 13 Amps |

| No Load Speed | 5000 RPM |

| Cord Length | 6 feet |

| Depth of Cut at 45 degrees | 1-3/4 inches |

| Depth of Cut at 90 degrees | 2-3/8 inches |

Loading...

Loading...