Do you have a question about the Craftsman 315.349720 and is the answer not in the manual?

Guidelines for using extension cords with the tool.

Information on motor speed and electrical wiring requirements.

Proper grounding procedures to reduce electric shock risk.

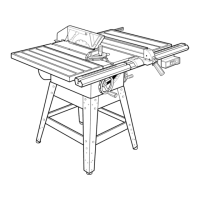

Lists the technical specifications of the table saw.

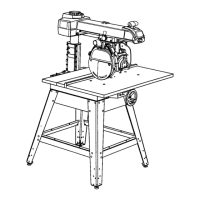

Familiarization with the tool's operating features and safety rules.

Explanation of kickback hazard and anti-kickback pawl function.

Describes the scale for exact blade angle measurement.

Details the included 10-inch carbide blade and its function.

Instruction to keep the blade guard down for through-sawing cuts.

Lever to lock the blade's angle setting in place.

Tool to align wood for cross cuts, showing exact angle.

Grooves on the saw table where the miter gauge operates.

Table extension at the back for supporting long workpieces.

Guides workpiece for lengthwise cuts, secured by a handle.

Metal piece to keep kerf open and prevent kickback.

Scale on the front rail for precise rip cut measurements.

Table extension on the right for wide workpieces.

Features a locking mechanism to prevent unauthorized use.

Describes the upper portion of the blade and table adjustments.

Recommended blade usage and kerf width limits.

Lists tools required for assembly and adjustments.

Instructions for safely unpacking and inspecting the tool.

Details on securing the table saw to a workbench or leg stand.

Step-by-step guide to assemble the quickstand leg system.

Instructions for attaching the saw to the assembled quickstand.

Steps to install the handle for the height/bevel adjusting handwheel.

Procedure for removing and reinstalling the throat plate.

How to adjust the riving knife for different cutting operations.

Verifying the correct installation and direction of the saw blade.

Instructions for installing safety features like pawls and guard.

Procedure to ensure proper alignment of the blade and riving knife.

Steps to install the sliding table extension.

How to install the indicator for the sliding table.

Guidance on storing accessories and the leg stand.

Lists the various cutting operations the tool can perform.

General guidelines for operating the table saw safely.

Explains the reasons behind kickback incidents.

Provides methods and precautions to prevent kickback.

Describes push sticks, push blocks, and featherboards.

Instructions for creating a jig for cutting narrow workpieces.

Information about using an auxiliary fence for thin materials.

Guide to making and attaching an auxiliary fence.

Explains featherboards for workpiece control.

Steps to construct a featherboard.

Guide on properly mounting a featherboard.

Details the six basic types of cuts the saw can perform.

Provides advice for making better and safer cuts.

How to adjust the blade height for cutting depth.

Procedure to calibrate the bevel indicator.

Steps for tilting the blade to achieve bevel cuts.

Calibrating the rip fence scale for accurate measurements.

Instructions on how to properly use the rip fence for cuts.

Guide on using the miter gauge for angled cuts.

How to extend the saw table for larger workpieces.

Using the outfeed support for long workpieces.

Aligning the blade parallel to the miter gauge groove.

General advice before making various types of cuts.

Step-by-step guide for making a cross cut.

Instructions for performing a rip cut.

Guide for making angled cuts using the miter gauge.

How to make a cross cut with a beveled blade.

How to make a rip cut with a beveled blade.

Guide for making cuts with both a miter and bevel angle.

Safety and procedure for cutting large panels.

Instructions for making cuts that do not go through the material.

Procedure for making dado cuts using a stack dado set.

Step-by-step guide for replacing the saw blade.

How to set the blade to 0° and 45° angles accurately.

Procedure to ensure the rip fence is parallel to the blade.

Routine care and upkeep for the table saw.

Basic cleaning and maintenance procedures.

Information on lubrication requirements for the tool's bearings.

| Type | Table Saw |

|---|---|

| Motor Power | 15 Amp |

| No-Load Speed | 5000 RPM |

| Power Source | Electric |

| Blade Diameter | 10 inches |

| Arbor Size | 5/8 inches |

| Bevel Capacity | 45 degrees |

| Dust Port Size | 2.5 inches |

Loading...

Loading...