48

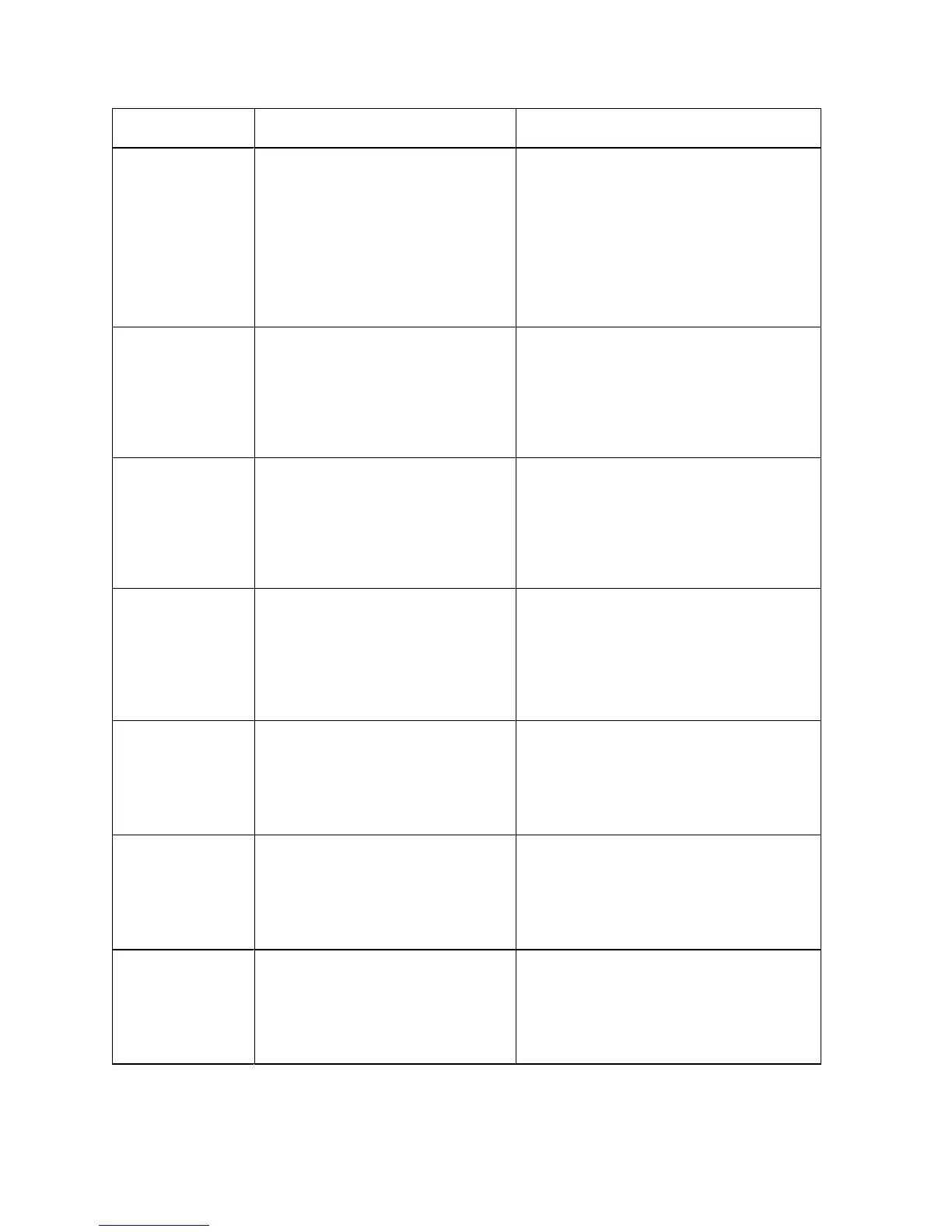

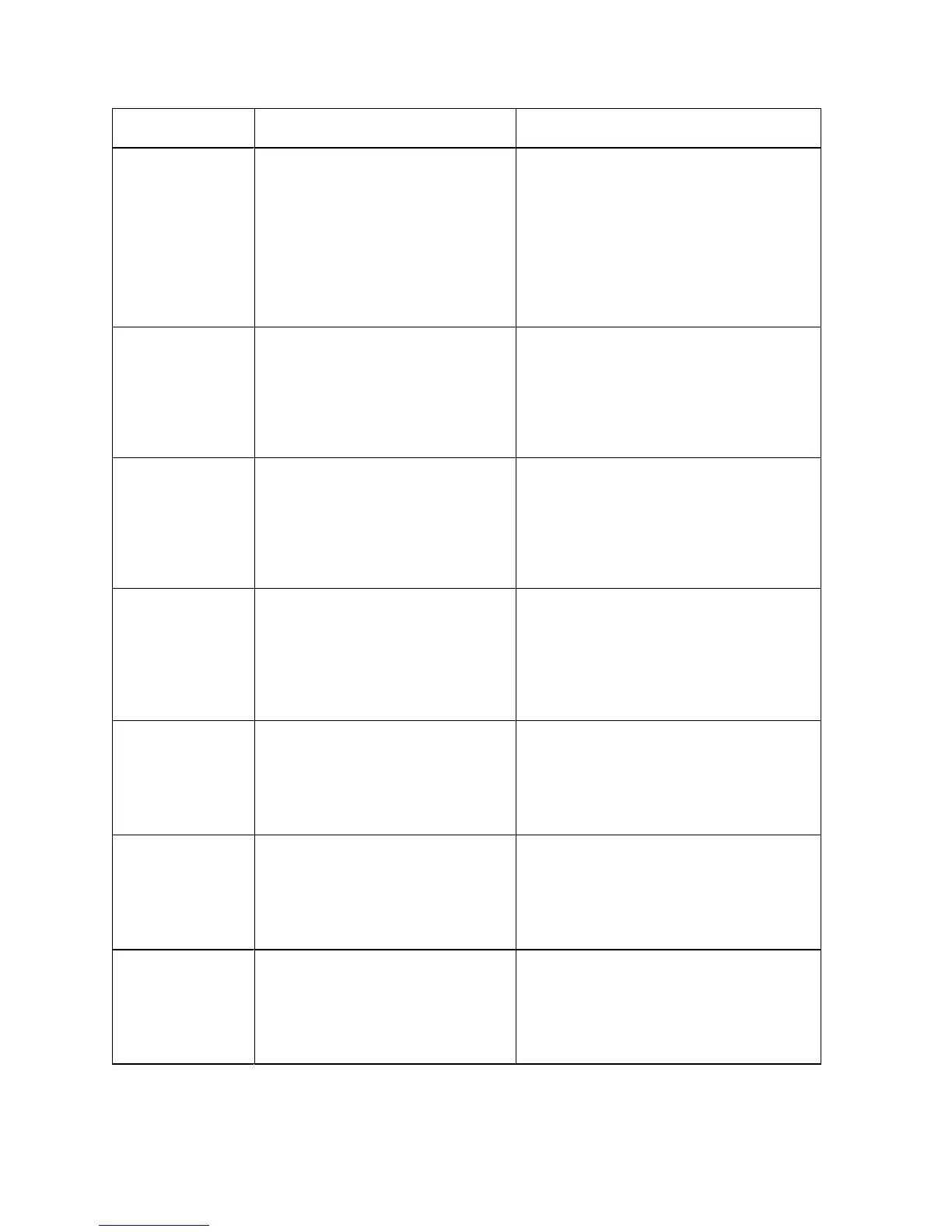

Table 4.1.2: Error Code Troubleshooting

Protective

Functions

Causes Solutions

Over-Current

Protection

1.

Faster acceleration and

deceleration time than load inertia

requirements.

2.

Larger load than the rated

capacity of the drive.

3.

Driving while motor coasting.

4.

Traverse worm gear speed

reducer using default stop mode,

F20

(1: Ramp to Stop)

1.

Extend acceleration and deceleration

time (User Function 7 & 8).

2.

Upgrade the drive capacity.

3.

Start driving after motor stops.

4.

Set

F20

, Stop Mode to (2: Immediate

Stop).

Over-Voltage

Protection

1.

Too short of deceleration time

compared to load inertia.

2.

Excessive regenerative energy on

the load side of drive.

3.

Excessively high input voltage.

4.

Noisy electrical environment.

1.

Extend deceleration time (User Function

8).

2.

Check Dynamic Braking Resistance.

3.

Check the input power supply.

4.

Correct input power or add 3%

impedance line reactor.

Current Limit

Protection

(OLt)

1.

Larger load than the drive’s rated

capacity.

2.

Incorrect setting of the drive

capacity.

3.

Incorrect setting of V/F pattern.

4.

Bumping fixed objects.

1.

Upgrade the motor and the drive

capacity in accordance with the load.

2.

Reset the drive capacity (F8).

3.

Adjust V/F pattern (F14 and/or H2 – H5).

4.

Verify OLt time duration is adequate for

application.

Heat-Sink

Overheat

1.

Failed cooling fan or foreign

object in the fan.

2.

An abnormal condition in the

cooling system.

3.

High ambient temperature.

1.

Remove the foreign object, or replace the

cooling fan.

2.

Check the heat-sink fins.

3. a.

Lower the ambient temperature below

104

°

F (40

°

C)

b.

Ventilate or air condition control

enclosure

Electronic

Thermal Detection

(EtH)

1.

Larger load than the rated current

of the drive.

2.

Low ETH level.

3.

Error in setting the drive capacity.

4.

Error in setting the V/F pattern.

1.

Replace drive, or upgrade the capacity.

2.

Adjust EtH level (H32). See Section

5.3.10.

3.

Reset the drive capacity (F8).

4.

Adjust V/F pattern (F14 and/or H2 – H5).

Phase

Fault

1.

One of the output wires from (U,

V, W) to motor is open.

2.

Setpoint of Motor No Load

Current is too high.

1.

Make sure the motor leads are

connected tightly at drive terminals (U,

V, W) and at motor.

2.

Verify motor data and adjust H20, H21

and H22 as necessary. See Section 3.3.

Low Voltage

Protection

1.

Low voltage input supply.

2.

Larger load than the rated power

capacity of the drive.

3.

Faulty magnetic mainline

contactor in power circuit.

1.

Check the input power voltage.

2.

Upgrade power capacity.

3.

Replace magnetic mainline contactor.

Loading...

Loading...