Do you have a question about the Crane DEMING 4507 Series and is the answer not in the manual?

Inspect pump for damage or shortages upon arrival; file claims immediately.

Guidelines for short-term and long-term storage to maintain performance.

Contact information for Deming Service Centers in USA and Canada.

Verify motor rotation direction is clockwise when looking down on motor.

Recommended lubrication for motor bearings and thrust bearing.

Steps to adjust impeller clearance for wear compensation.

Disconnect lines, remove pump, casing, base, and strainer.

Remove impeller, coupling, motor, and pump shaft assembly.

Procedures for replacing thrust bearing, grease seal, and bushing.

Assemble motor support, casing, and pump shaft unit.

Install impeller, washer, nut, and suction strainer.

Assemble coupling, motor, discharge pipe, and float switch.

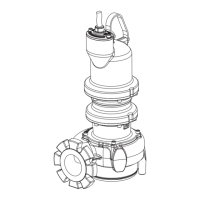

This document is an Installation, Operation, & Maintenance Manual for the Deming® Series 4507 Sump Pump, specifically for 2, 3, 4, and 6-foot models. It is noted that the product is discontinued and parts may not be available.

The Deming Series 4507 is a sump pump designed for various applications, as indicated by its installation, operation, and maintenance manual. Sump pumps are generally used to remove water that has accumulated in a sump pit, commonly found in basements or crawlspaces, to prevent flooding. Given the "Installation, Operation & Maintenance Manual" title, it provides comprehensive instructions for setting up, running, and servicing the pump to ensure its longevity and efficient performance. The manual emphasizes safety precautions, proper installation, and regular maintenance to prevent equipment problems and ensure safe operation.

| Brand | Crane |

|---|---|

| Model | DEMING 4507 Series |

| Category | Water Pump |

| Language | English |

Loading...

Loading...