A Crane Co. Company

BARNESBARNES

®

INSTALLATION and OPERATION MANUAL

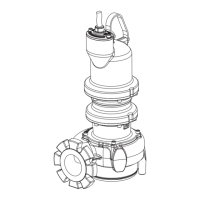

Submersible Sewage Non-Clog Pumps

IMPORTANT! Read all instructions in this manual before operating pump.

As a result of Crane Pumps & Systems, Inc., constant product improvement program,

product changes may occur. As such Crane Pumps & Systems reserves the right to

changeproductwithoutpriorwrittennotication.

420 Third Street 83 West Drive, Brampton

Piqua, Ohio 45356 Ontario, Canada L6T 2J6

Phone: (937) 778-8947 Phone: (905) 457-6223

Fax: (937) 773-7157 Fax: (905) 457-2650

www.cranepumps.com

Form No. 140838-Rev. C

Series: 4SEV-DS, 2.8, 3.7 & 5HP

1750RPM, 60Hz