Fume Hood Monitor and Controller – User Guide 11 © 2016 CRITICAL ROOM CONTROL

Immediate Valve Control (IVC™) – Sash Sensing

Unlike conventional hood controllers that merely rely on a PI loop to slowly react to changes in

sash position, CRC fume hood controller’s Immediate Valve Control (IVC)™ technology continually

measures sash position and current CFM at a rate of 5 times per second to immediately react to

a change in sash position and instantly drive our valve to the correct valve position to maintain

face velocity.

CRC’s IVC™ algorithms utilize an air flow table that is created with an automated process that

takes less than 20 seconds during the commissioning of the fume hood.

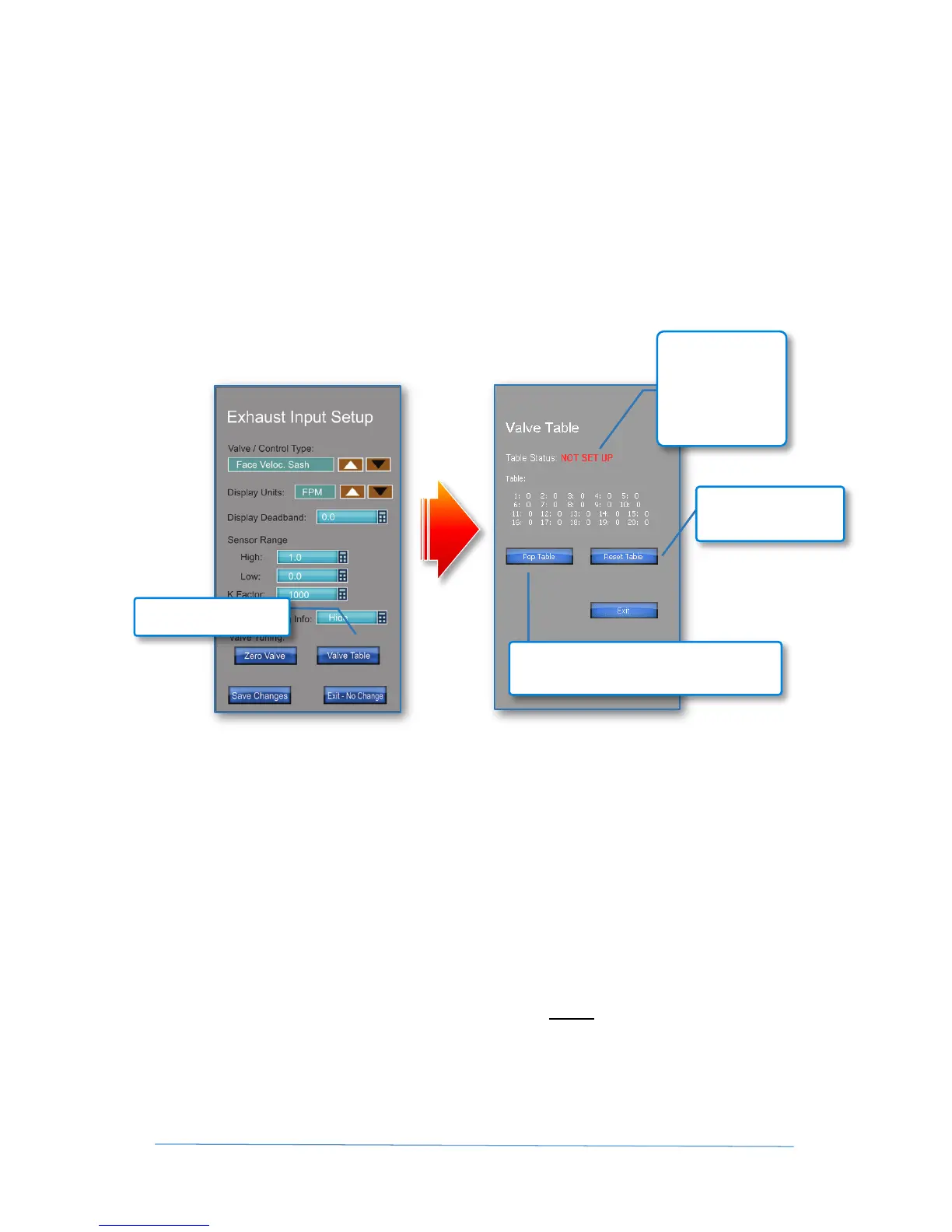

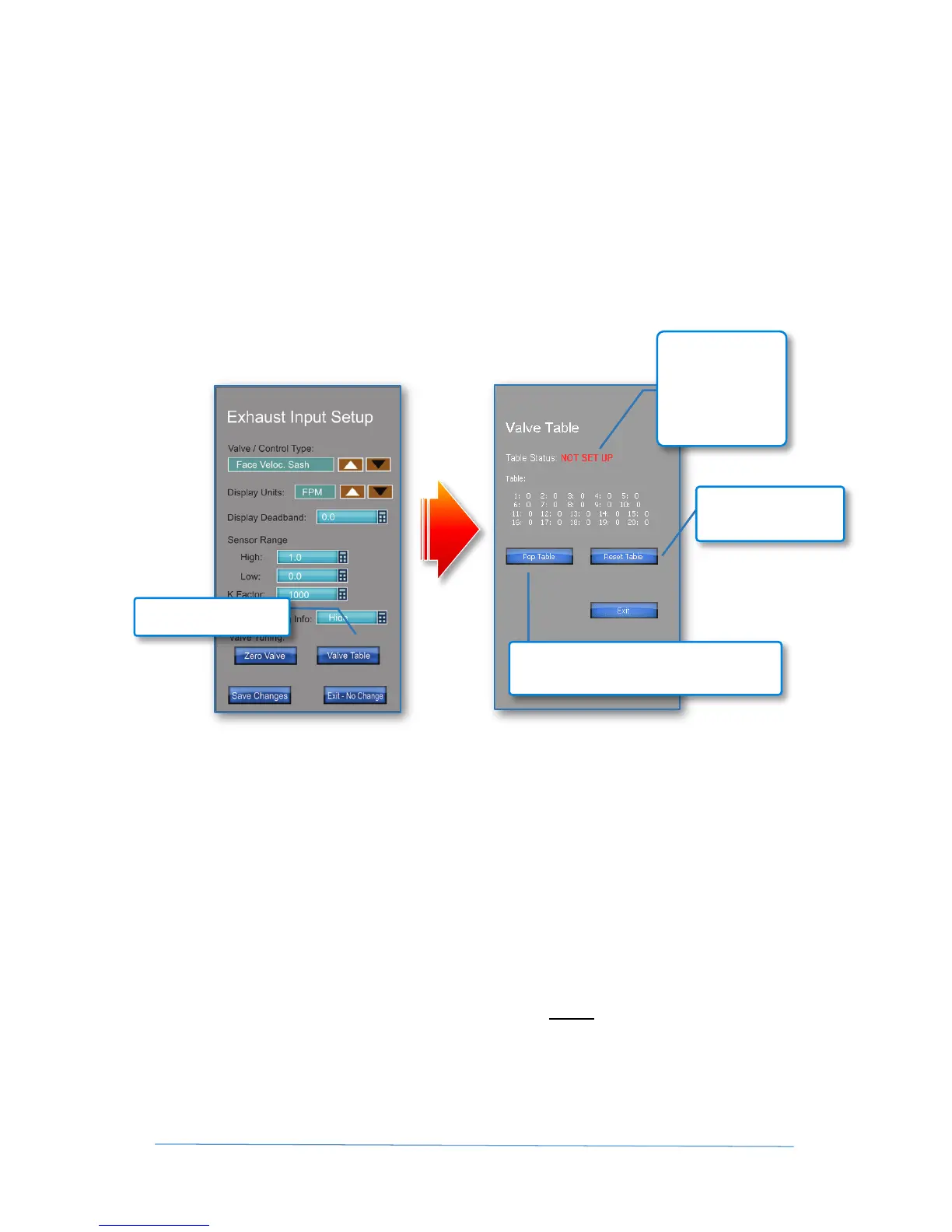

To create this table, simply click on the “Valve Table” button on the Exhaust Input Setup screen

to show the “Valve Air Flow Table” screen.

To setup / enable IVC, first confirm that the exhaust flow is running at the lowest static pressure

to be used during operation, then press the “Pop Table” button to auto populate the flow values

of the hood’s exhaust valve. After pressing this button, the controller automatically records the

valve’s flow rate for different key actuator positions. This process takes approximately 20 seconds

to complete. When finished, the table status should read “NO ISSUE”.

To disable IVC, click the “Reset Table” button.

Please note the following:

• Changing the valve’s “K Factor” will NOT effect the table. Once the table is created – the

table values will automatically adjust to changes in K Factor.

• For optimized performance, the exhaust flow should be running at the lowest static

pressure to be used during operation of the hood before pressing the “Pop Table”

button.

• If “Zero Valve” status is displayed, then go through the Valve Zeroing process outlined

on previous page before repopulating the valve’s airflow table.

Loading...

Loading...