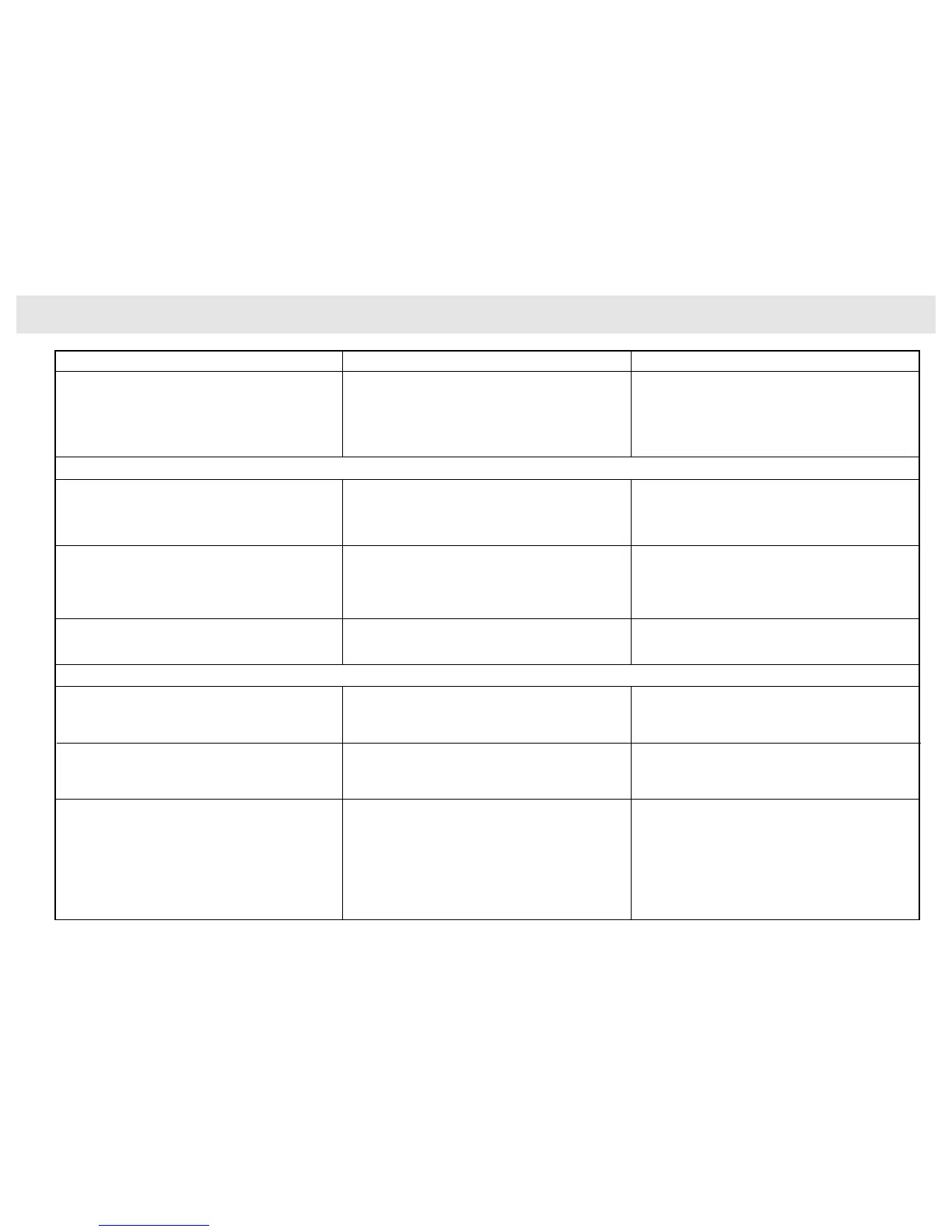

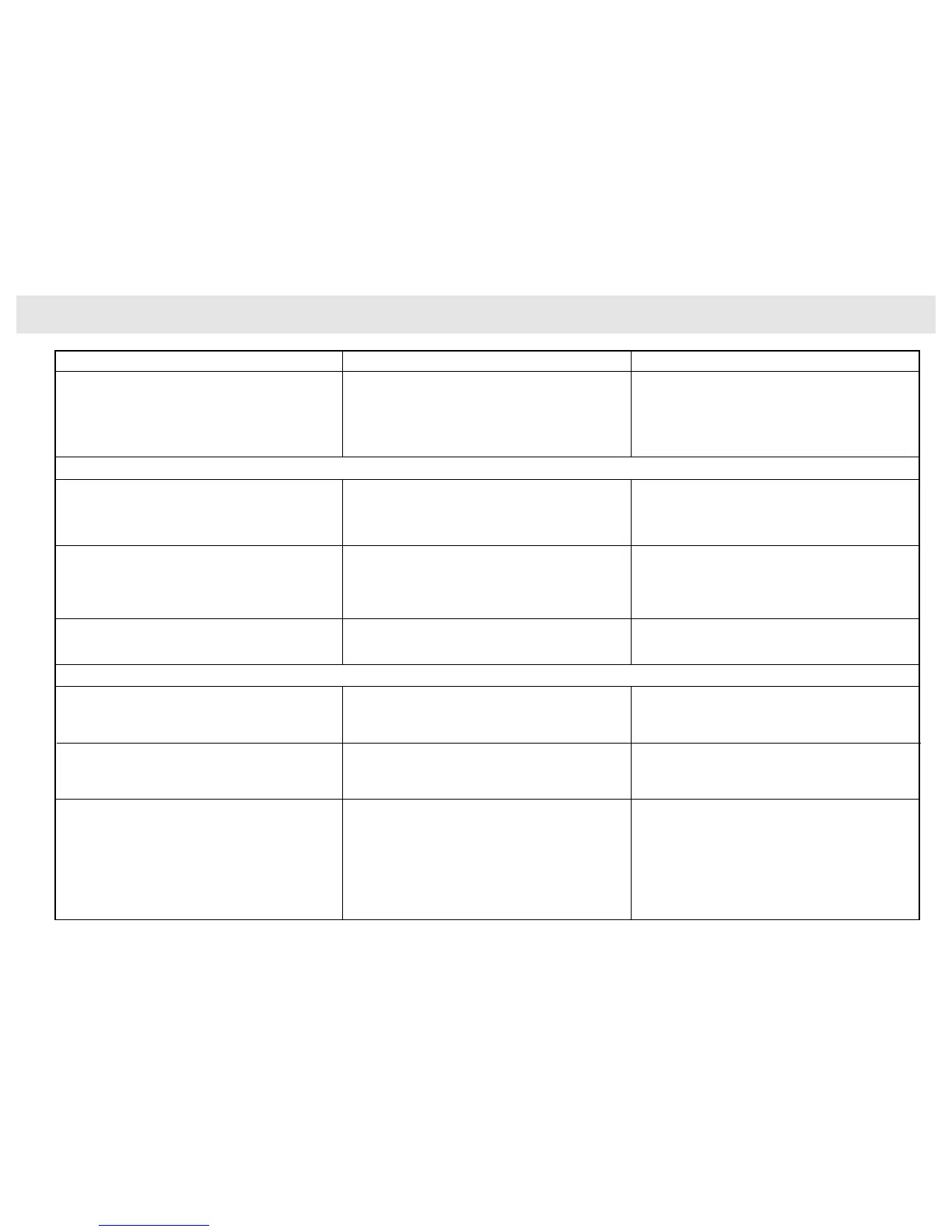

6.3

Pinto BT-POM 1212 - Revision 5

Section 6 Diaphragm Pump Problems

PROBLEM

E Oil being discharged through delivery

line or dis col oured oil in sight glass of

pump.

F Suction hose vibration.

G Pump valves hammering.

H No water fl ow on suction hose.

I Pressure gauge pointer swings vi o lent ly.

J Control valve leaking from spindle.

K Pressure gauge showing correct

working pres sure no pressure at

nozzle.

PROBABLE CAUSE

1 One or more diaphragms split or ruptured.

SUCTION SIDE OF PUMP

1 Air getting into suction.

1 Suction tap partly turned off.

2 Suction strainer(s) blocked.

1 Obstruction in tank or suction line.

DISCHARGE SIDE OF PUMP

1 Pressure control valve spindle doesn’t move

easily.

1 Split diaphragm or O-rings.

1 Burst discharge line.

2 Blocked pressure fi lter where fi tted.

3 O-ring(s) jamming fl ow in discharge line.

4 Ants, wasps build nests in discharge line or

nozzles.

REMEDY

1 Immediately drain oil from pump and fl ush to

remove all spray residues from sump. Remove

pump heads & fi t new diaphragms.

Fill to correct level with motor oil 20W/30.

1 Seal all joints securely with tape or sealant.

Firm up clamps.

1 Turn tap fully on.

2 Clean fi lters.

1 Clean foreign material from tank & suction line.

1 Lubricate with light oil or C.R.C.

1 Remove 4 body set screws, replace

diaphragm and O-rings.

1 Replace discharge line.

2 Clean pressure fi lter.

3 Clean discharge line of foreign materials.

4 Clean nozzles of foreign materials with tooth

brush

Loading...

Loading...