6.2

Pinto BT-POM 1212 - Revision 5

Trouble Shooting

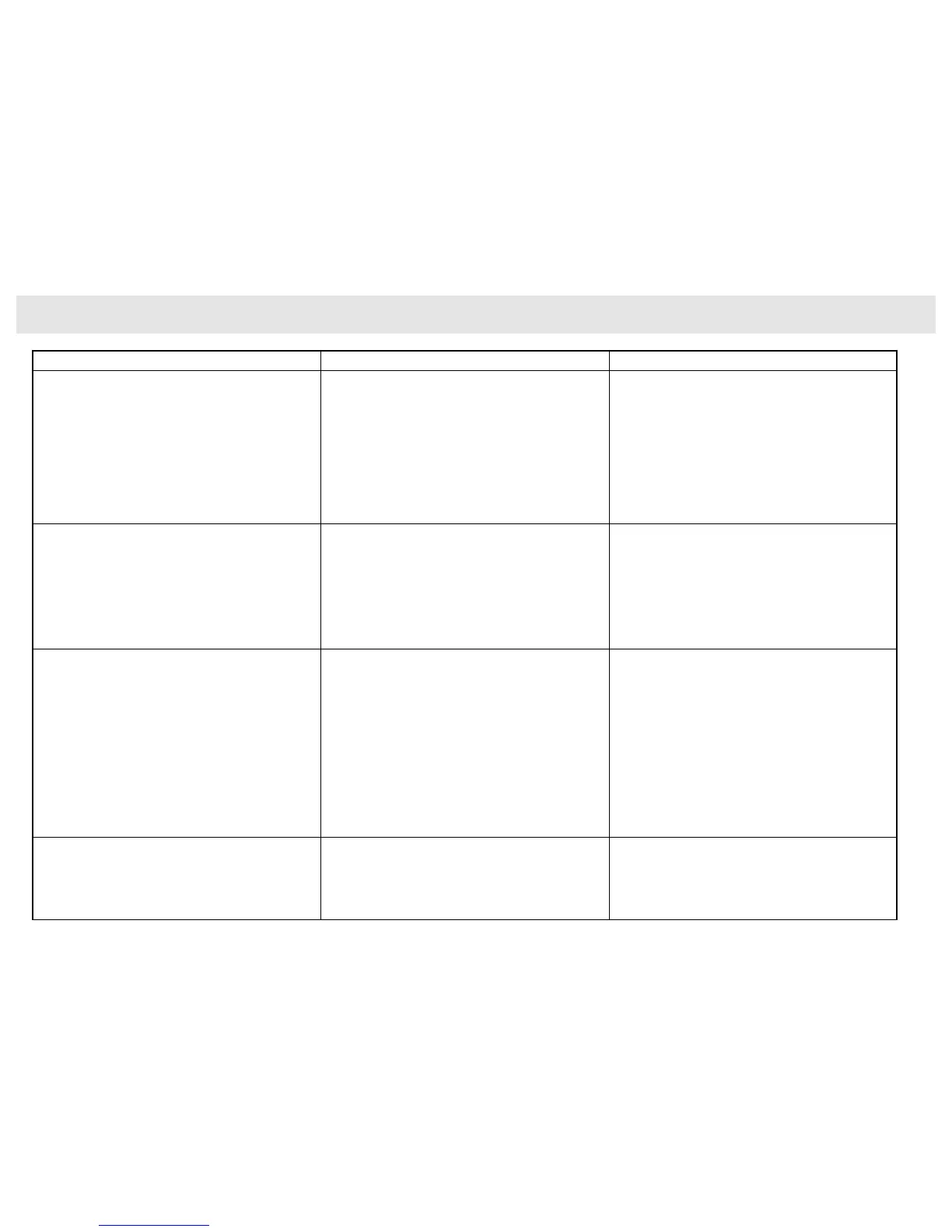

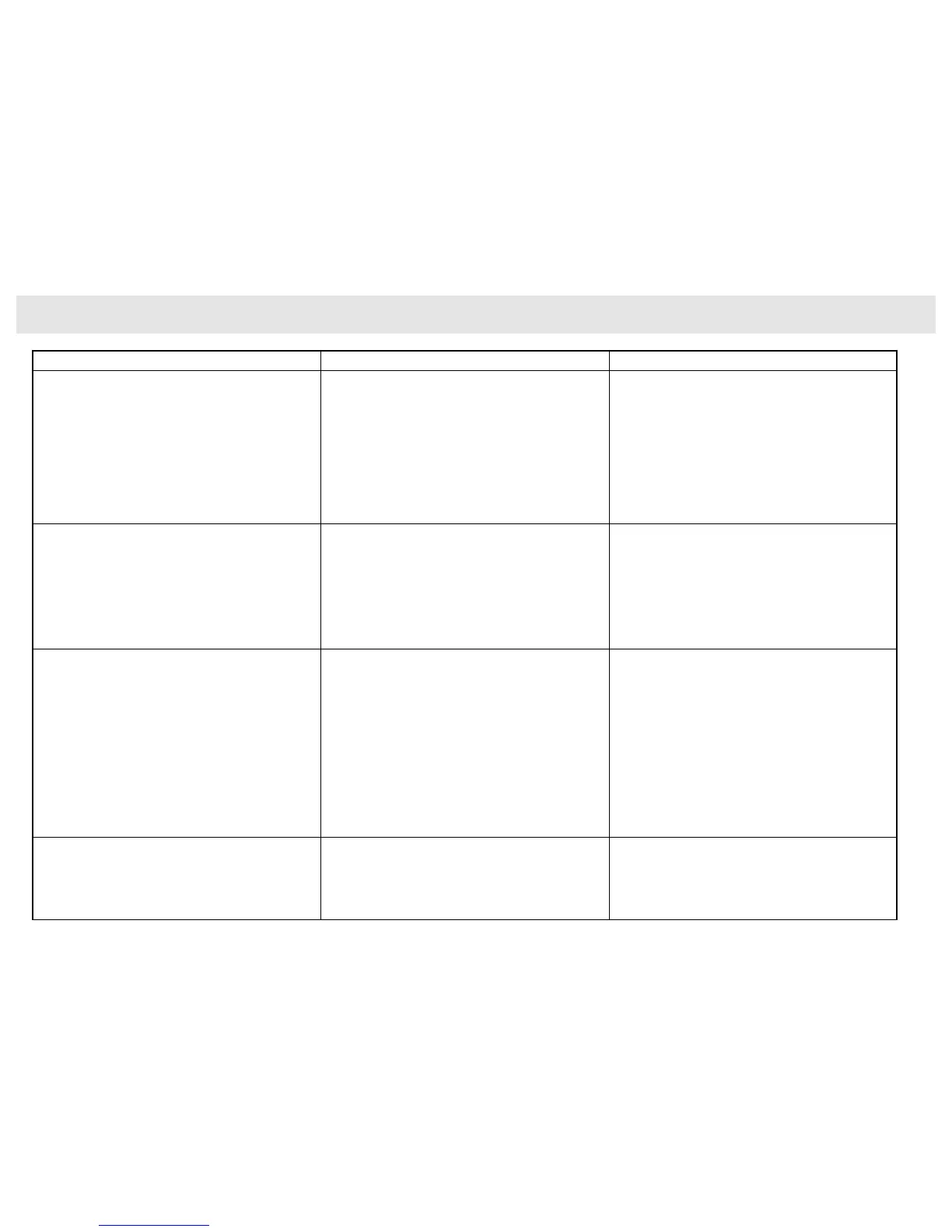

Diaphragm Pump Problems

PROBLEM

A Pump does not draw or deliver liquid.

Pressure gauge fl uc tu ates badly.

B Liquid fl ow is ir reg u lar

(Also check items un der A)

C Pump delivers in suf fi cient pressure

D Output drops & pump is noisy.

PROBABLE CAUSE

1 One or more valves are not seating prop er ly.

2 The pump is suck ing in air through suction line.

3 Air has not been entirely evacuated from the

pump.

4 Blocked suction fi lter.

5 Damaged or worn suction valves.

1 The air in the air chamber of the pump is

incorrectly set.

2 Diaphragm split.

3 Damaged or worn valves.

4 Foreign matter holding valves open.

1 Regulating valve:

• Sticking open

• Not set for pressure.

• Damaged or worn seat or spring.

2 Cylinder diaphragm ruptured.

3 Pump valves blocked, worn or damaged.

4 Spray nozzles worn, missing or exceed

pump capacity.

1 Oil level is too low.

REMEDY

1 Clean valve seat ing.

2 Examine the suc tion hose and ensure it is

fi rmly secured.

3 Rotate the pump with outlet hose and taps

open.

4 Clean suction fi l ter.

5 Replace suction valves.

1 Check pressure in air chamber of pump. Set

at 210-280Kpa (30-40 psi), or 10% of you average

spraying pressure.

2 Replace diaphragm.

3 Replace valves.

4 Clean valves.

1 Fix the regulator:

• Unstick the valves.

• Set the pressure.

• Replace the spring.

2 Replace diaphragms.

3 Unblock valves and or replace.

4 Replace spray nozzles with appropriate size.

1 Top up with oil to correct level (1/2 way up the

sump sight glass).

Loading...

Loading...