3.28

Pinto BT-POM 1212 - Revision 5

Sprayer Operation

Operating Pointers

Proceed to Spray

Once the chemical mixture is in the tank,

proceed to spray:

1 Adjust the pressure to the correct

operating pressure by adjusting

pressure (up or down) according

to the instructions of the Controller.

2 Turn spray booms ON and OFF as

required to spray according to the

instructions of the controller fi tted.

Refer to pages 2.21 - 2.24 for spray

controller operating instructions, &

pages 3.4 - 3.6 for foam marker

operating instructions.

Operating Pointers

While spraying, continually observe that:

1 Engine and PTO speed are correct.

2 Correct operating pressure is being

maintained.

3 Ground speed is correct and within

the operating range of the nozzles

and application rates selected.

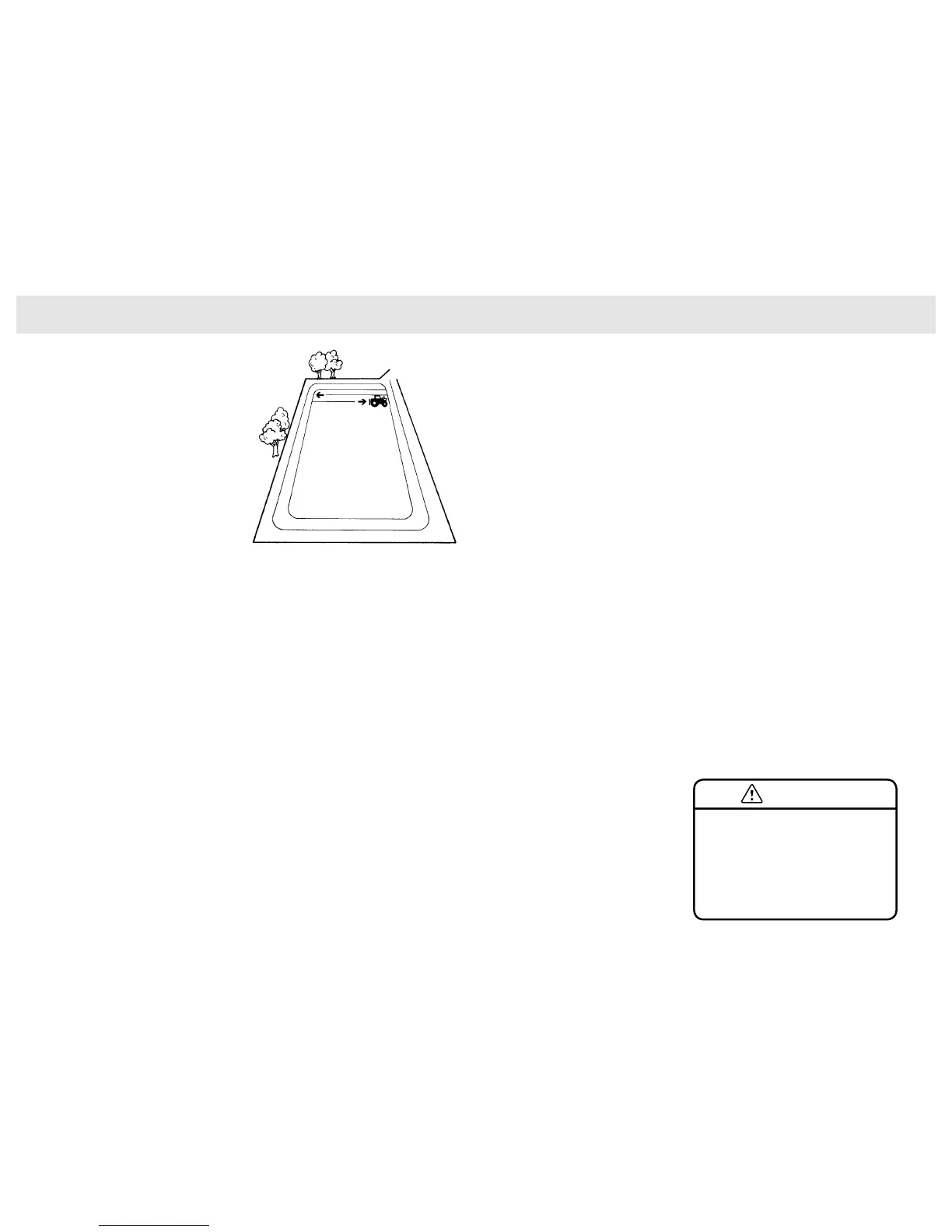

Operating Meth od ol o gy for

Broadacre Spraying

It is always preferable to spray travelling

across the wind direction.

This minimises any drift effect caused by

the wind especially with fl at fan nozzles

because the wind only hits the narrow end

of the pattern rather than the full face of

the fan spray.

It also maximises the effect of the wind

forcing droplets downwards into contact

with the target.

Travelling with the wind increases the

tendency of spray droplets to fl oat away

from the target, and travelling against the

wind effectively multiplies the force of the

wind (depending on speeds) increasing

drift and reducing target contact.

Running a diaphragm pump faster than specifi ed

will not improve performance, but will damage

and wear out moving parts.

Warranty will be made void by speeds in excess

of those indicated on the pump name plate.

CAUTION

Loading...

Loading...