4.6

Pinto BT-POM 1212 - Revision 5

Sprayer CalibrationCalibration Procedure

Step 7

Calculate Application Rate

When operating the spray controller, the

controller automatically calculates and

shows the rate of application.

Application Rate (l/ha) =

Spray Output (l/min) x 600 ÷

Speed (km/hr) x Swath Width (m)

eg, [18 x 600] ÷ [12 x 18]

= 50 l/ha

f) Discard and replace any nozzle that

deviates more than 10% from the

specifi ed output (eg with a 0.5 l/min

specifi cation- discard any nozzles

0.45 l/min and under or 0.55 l/min

and over).

g) Check replacement nozzles by

collecting and measuring output

from each replacement.

h) Record the output of each nozzle on

the boom. Add the outputs together

and divide by the number of nozzles

to get the required output of each

nozzles in one minute.

eg, Total spray output 18 l/min ÷

36 nozzles = 0.5 l/min per

nozzle.

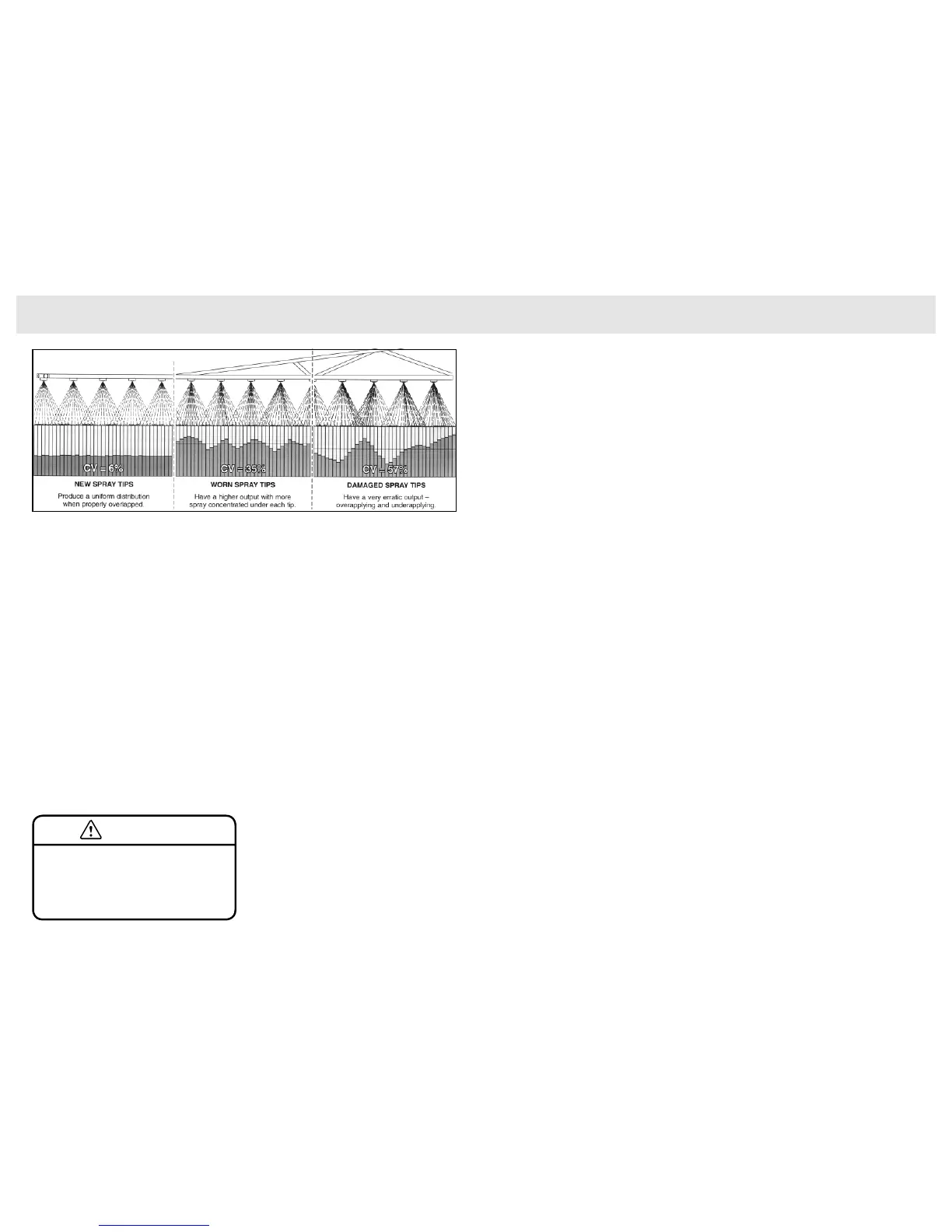

Spray tip wear - courtesy of Teejet.

c) Collect and measure the volume of

spray from one nozzle and adjust

pressure so that the nozzle gives the

specifi ed output (eg 0.5 l/min).

IMPORTANT:

Do not use a worn nozzle to set the

pressure setting and nozzle rates.

If the boom is not fi tted with new

nozzles, fi t one new nozzle and use it

to set the fl ow rate and pressure

setting.

This sets the standard fl ow rate,

pressure setting and spray pattern

with which to test the performance of

other nozzles.

Do not use a worn nozzles to set the pressure

setting and nozzle rates, otherwise inaccurate

calibration will occur.

CAUTION

d) When the pressure is set to give a

specifi ed nozzle output (using a new

nozzle), collect and measure the

volume of spray from each nozzle

for one minute in a collection jar or

calibrating jug.

Specially designed nozzle testing

equipment such as nozzle

calibrating jugs can be used to

simplify nozzle calibration.

e) Visually check nozzle spray patterns

and spray angle for accuracy and,

if necessary, replace any faulty

nozzles.

Loading...

Loading...