By following a careful service and maintenance

program for your machine, you will enjoy many

years of trouble-free service.

5.2.1 ENGINE OIL CHANGING

1. Review the Operator’s Manual for the

engine.

2. Allow the engine to cool before changing

oil. Hot oil can cause burns if it contacts

exposed skin. Draining works best if the

oil is warm.

3. Be sure the ignition switch is o and fuel

valve is turned o.

4. Place a pan under the drain plug.

5. Remove the drain plug and allow oil to

drain for 10 minutes.

6. Install the engine drain plug and tighten.

7. Dispose of the oil in an approved contain-

er.

8. Add the specied type and amount of mo-

tor oil. Refer to Section 5.1.1 or the engine

manual.

9. Run the engine for 1 minute and check for

leaks.

10. If leaks are found around the drain plug,

tighten slightly and repeat Step 12.

11. Check engine oil level. Top up as required.

5.2 MAINTENANCE

39

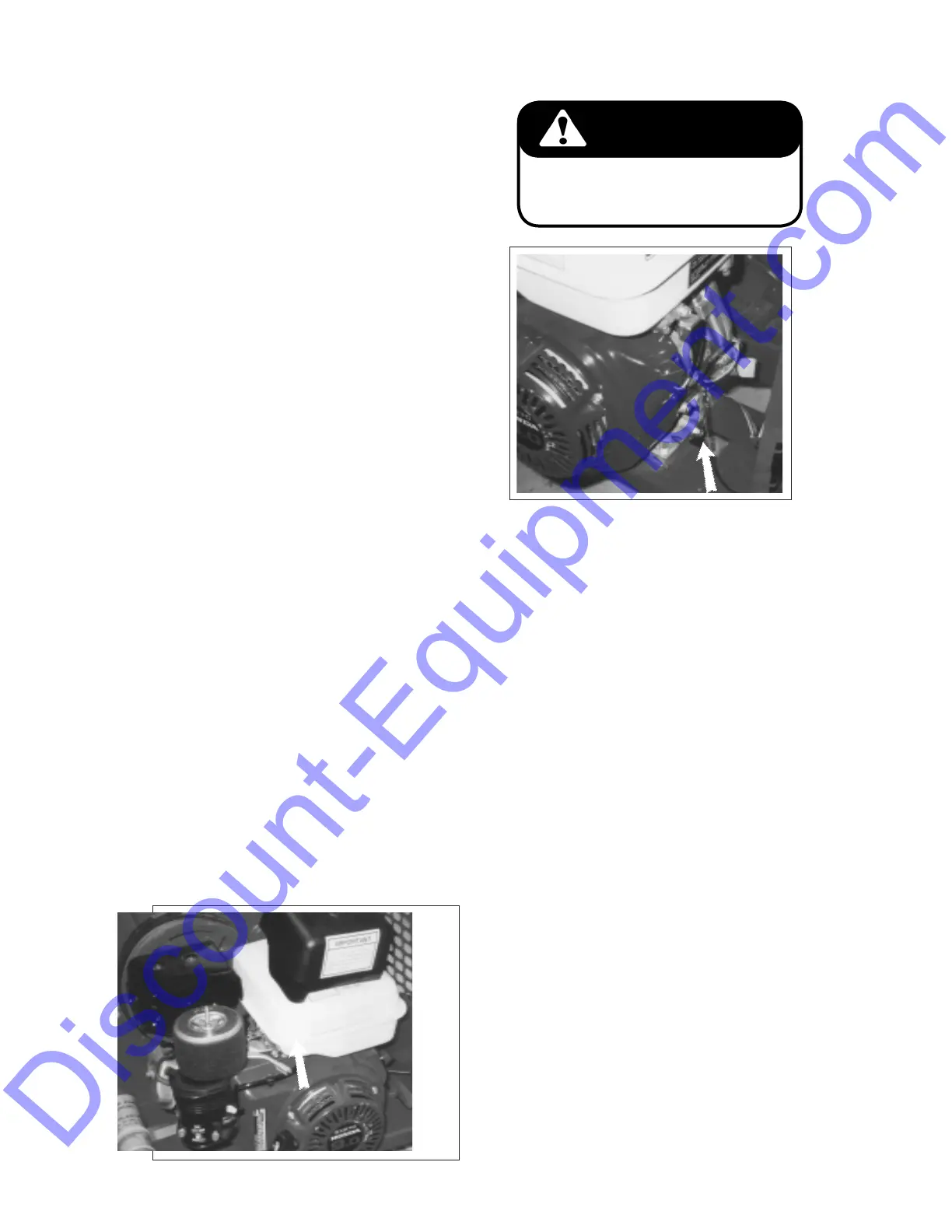

Machine is shown with engine hood open

for illustrative purposes only. Never oper-

ate with hood open.

WARNING

Fig. 30 ENGINE OIL CHANGING (DRAIN PLUG)

5.2.2 ENGINE SPEED SETTING

Every engine is shipped from the engine fac-

tory without gas or oil because of re hazards

during shipping. They are all set with a high

idle of 3500 RPM. Since no uids are added at

the Mixer factory, the RPM is not reset. When

the Mixer is delivered, the uids must be

added and the RPM reset. To reset the RPM,

follow this procedure:

1. Read the engine manual supplied with

the machine.

2. Add fuel and the specied motor oil to

the crankcase and oil to the gearbox.

3. Start the engine and run at wide open

throttle.

4. Use a screwdriver to reset the high idle

stop screw.

5. Count the mixing element revolutions to

determine engine RPM. Set the engine

speed to give 30-35 RPM for the paddles

and 40-45 RPM for the spiral when mixing.

6. Load the drum and count the mixing ele-

ment rotational speed again.

7. Reset if the speed changes as required.

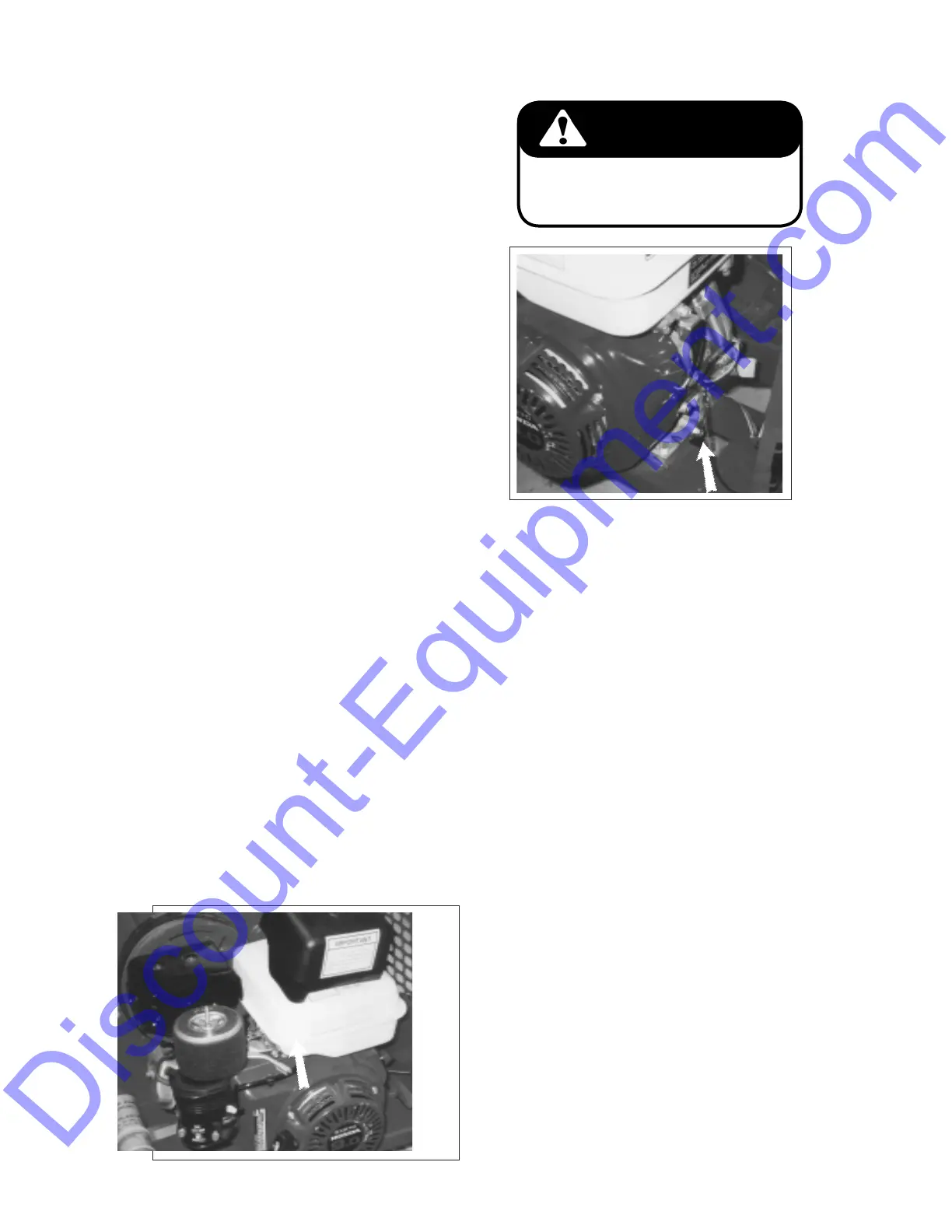

Fig. 31 ENGINE SPEED SETTING

Loading...

Loading...