5.2.3 AIR CLEANER MAINTENANCE

Each engine is equipped with lter to remove dust

41

and dirt from entering the air intake. To clean

the lter, follow this procedure:

1. Read the engine manual supplied with the

machine.

2. Unlatch and open the hood.

3. Remove the lter cover.

4. Remove lter and shake out.

5. Wash in a lter cleaning detergent if

heavily caked with dirt. Allow time to dry

before re-installing.

6. Replace lter after washing 5 times.

7. Install clean lter and secure cover.

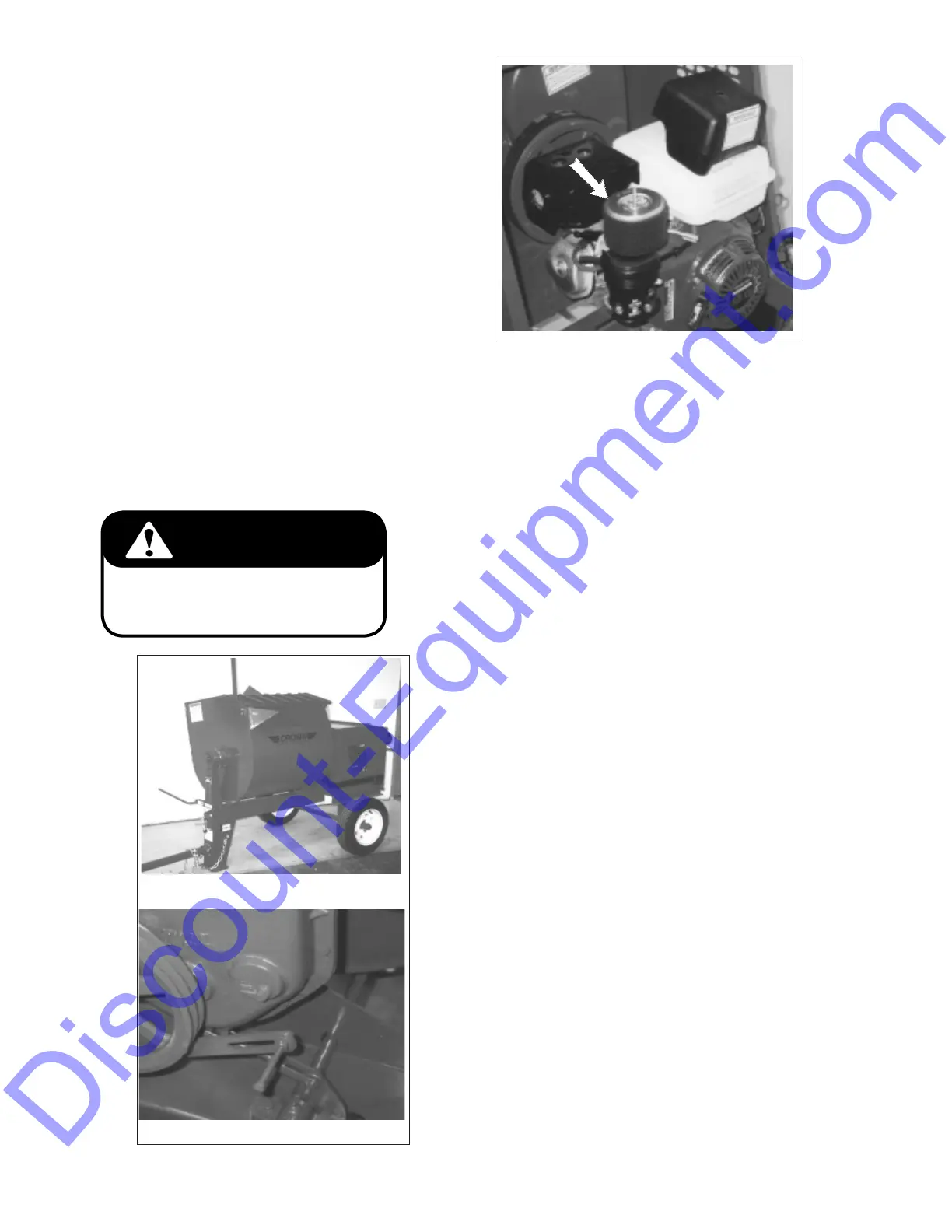

Machine is shown with engine hood open

for illustrative purposes only. Never oper-

ate with hood open.

WARNING

Fig. 32 AIR CLEANER

5.2.4 BELT TENSION AND ALIGNMENT

A drive belt and pulley system transmits power from the

motor or engine to the gearbox for rotating the

mixing elements. A clutch lever through an over

center linkage swings the gearbox and pulley over

to tighten and engage the drive. The belt tension

must be properly set when the clutch is engaged

to prevent slipping and the pulleys aligned to pre-

vent belt wear. To set the tension and alignment,

follow this procedure:

1. Unlatch and open hood.

2. Disable power source by unplugging power

cord or disconnecting spark plug wire.

3. Remove the pins on each end of the linkage

arm.

4. Lengthen or shorten linkage arm length by

turning yokes on the threaded rod.

5. Repin linkage arm.

6. Engage clutch. There should be a denite

feeling when the clutch linkage goes over

center. If not readjust linkage.

7. The belt is properly tensioned when the mid-

span deects 1/4 inch (6 mm) when pushed

on with a 10 lb force.

8. Align the pulleys by loosening the motor or

engine mounting bolts.

9. Slide or tap the power unit into position to

align the pulleys.

10. Tighten power unit mounting bolts to their

specied torque.

11. Close and secure the hood.

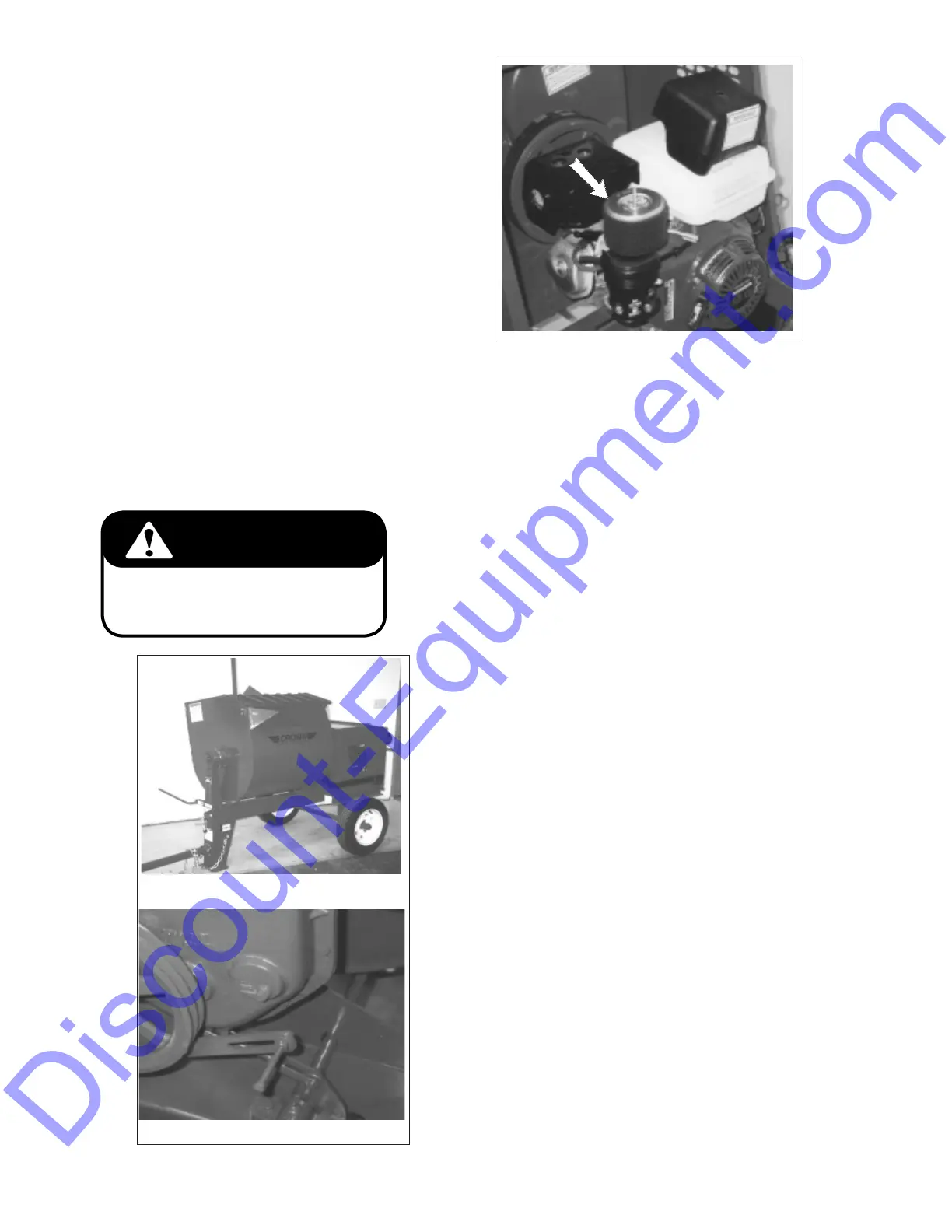

Fig. 33 BELT TENSION AND ALIGNMENT

Clutch Linkage (Typical)

Clutch Engaged

Loading...

Loading...