3

WARNING

Lubricants

Do NOT use Vaseline, oils, hydrocarbon lubricants or spray silicone anywhere! Petroleum base lubricants will cause

swelling of o-rings and seals. The use of other lubricants may attack plastic Noryl®. It is recommended that Dow

Corning® silicone grease be used as a lubricant for all control valves. Dow Corning® 7 Release Compound is used in the

manufacture of Chandler Systems control valves. (Part # LT-150)

Sealants

Pipe dope and liquid thread sealers may contain a carrier that attacks some plastic materials. It is recommended that

Teflon® tape be used to seal plastic Noryl® threaded fittings.

Softener Specifications

General Specifications

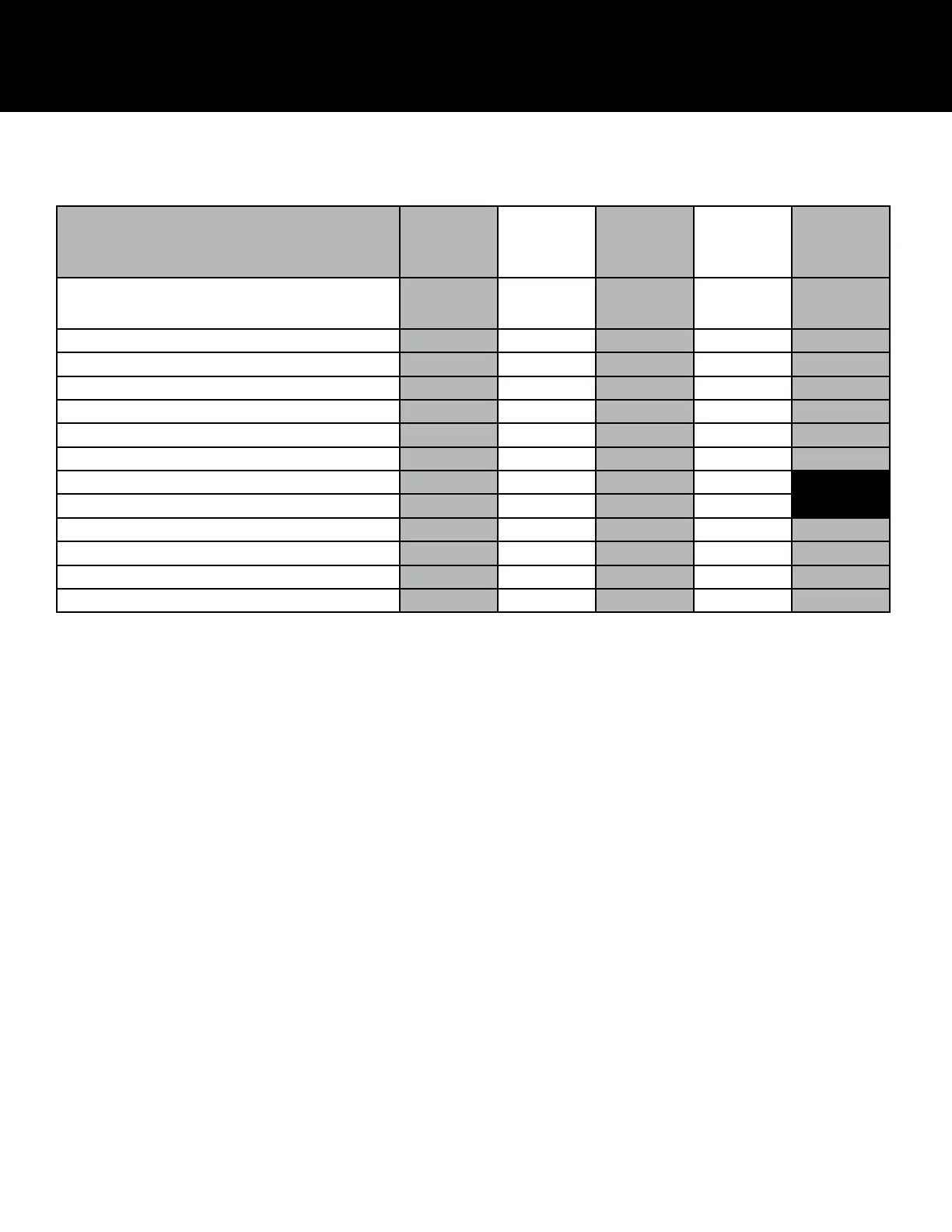

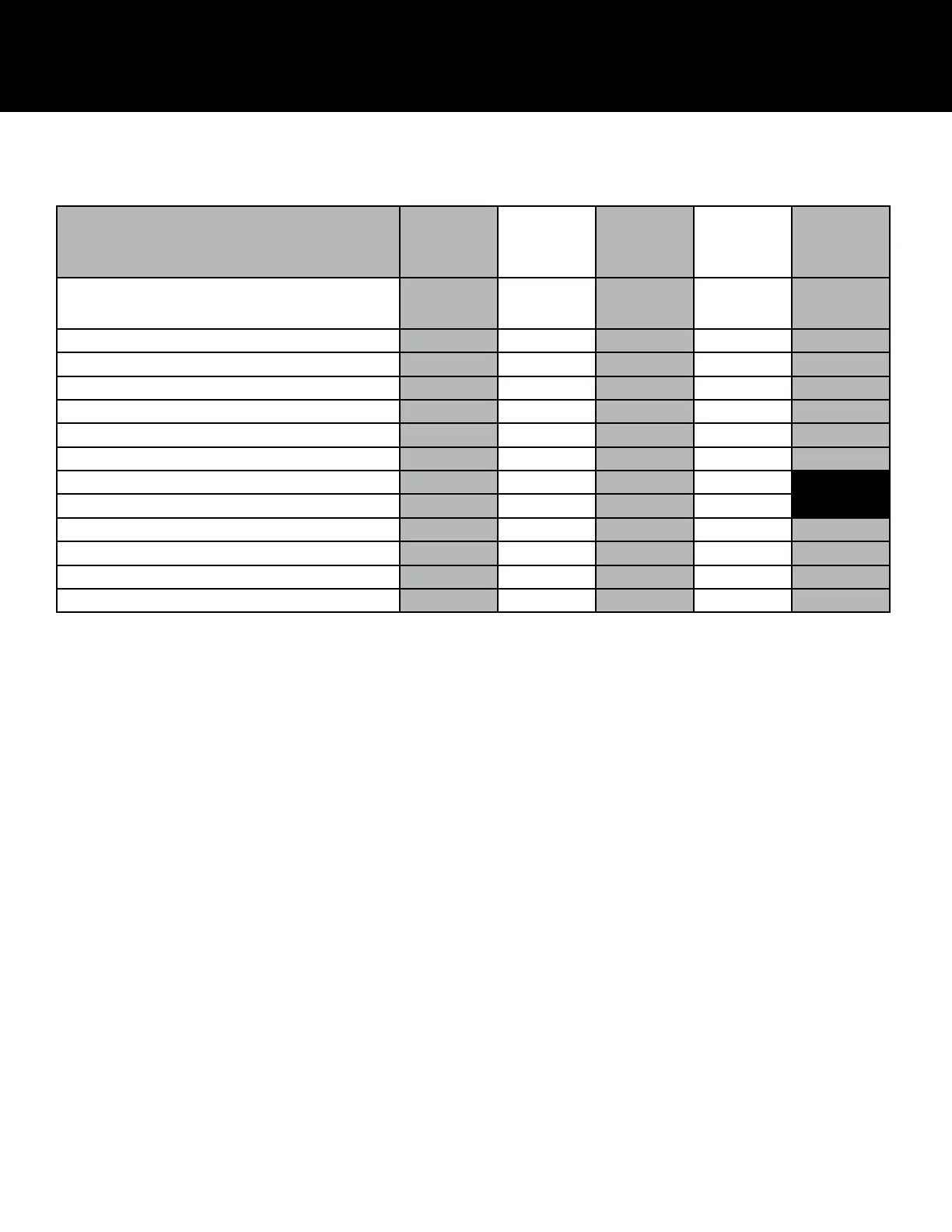

MS24-S2

MS24V-S2

MS24-S3

MS24V-S3

MS32-S2

MS32V-S2

MS32-S3

MS32V-S3

MS48-S2

MS48V-S2

MS48-S3

MS48V-S3

MS64-S2

MS64V-S2

MS64-S3

MS64V-S3

MS96V-S2*

MS96V-S3*

Grains Capacity -

Regeneration / Lbs Salt Used**

24,000 / 12

20,000 / 7.5

15,000 / 4.5

32,000 / 15

27,000 / 9

20,000 / 6

48,000 / 24

40,000 / 15

30,000 / 9

64,000 / 30

54,000 / 18

40,000 / 12

96,000 / 45

81,000 / 27

60,000 / 18

Maximum Raw Water Hardness (grains) 50 75 100 100 100

Maximum Clear Iron / Manganese 3 5 5 5 5

Exchange Resin (cu ft per tank)

.75

1.0 1.5 2.0 3.0

Mineral Tanks (polyglass) 8 x 44 9 x 48 10 x 54 12 x 52 13 x 65

Brine Tank (polyethylene w grid & safety) 18 x 33 18 x 33 18 x 33 18 x 33 18 x 40

Service Flow Rate (gpm per active tank)*** 8.0 10.0 11.0 12.0 14.0

Backwash Flow Rate (gpm) 1.5 2.0 2.4 3.5

Gallons Used / Regeneration 79 90 101 140

Backwash Flow Rate (gpm) Vortech (V) Units 1.2 1.5 2.0 2.4 3.0

Gallons Used / Regeneration Vortech (V) Units 69 78 90 117 126

Space Required

18 X 26 X 53 18 X 27 X 56 18 X 28 X 62 18 X 30 X 60 18 X 32 X 74

Approximate Shipping Weight (lbs) 88 100 133 164 285

*96 Series only available in Vortech Units

**Factory Salt Settings are 9 lbs / cu ft

***The pressure drop does not exceed 15 psi at the service flow rate

Loading...

Loading...