62 Culligan® CSM Series Softeners

62 Cat. No. 01016370

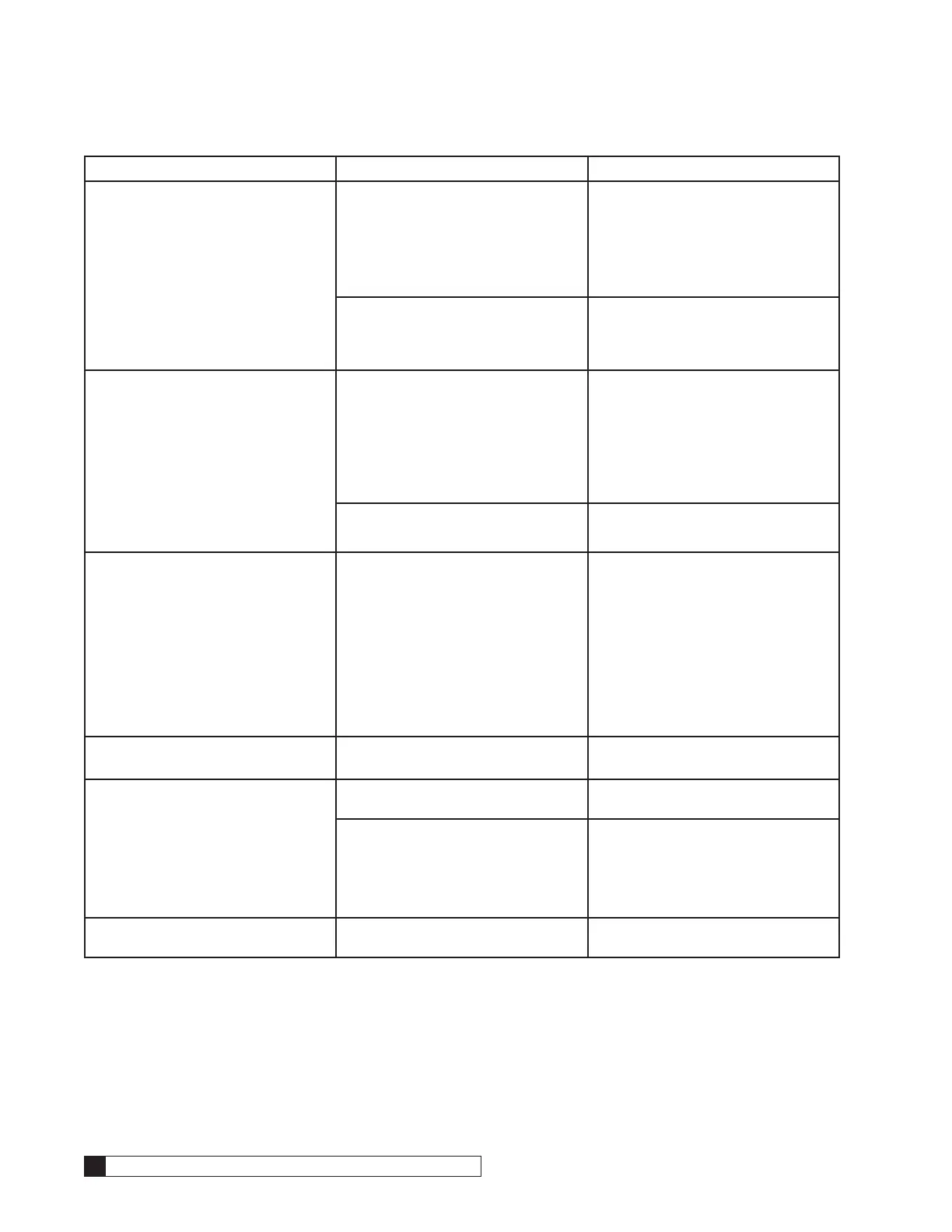

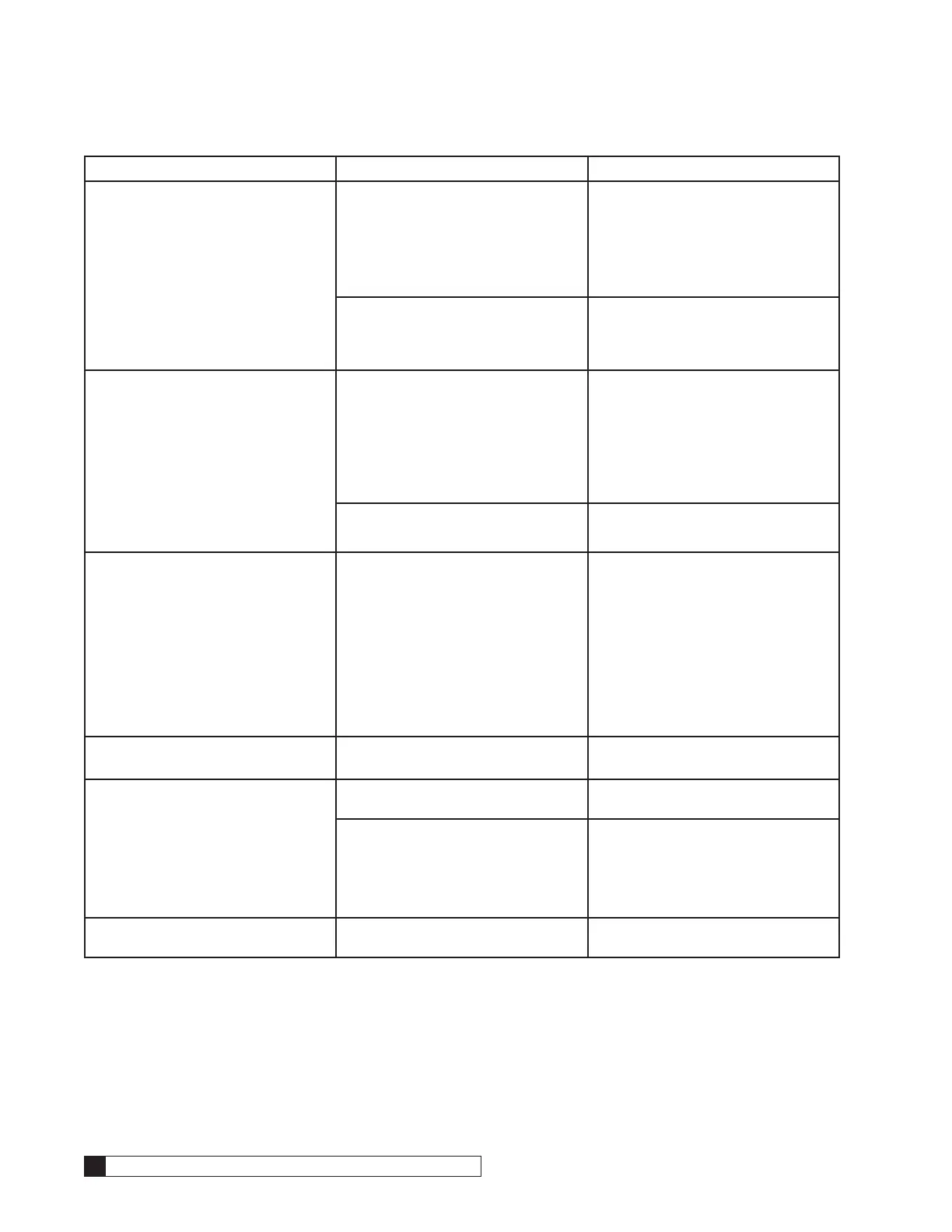

PROBLEM OR SYMPTOM CHECK PROCEDURE CAUSE

Hard Water Leakage Into the Service

Lines.

CAUTION: make certain that the

water pressure is relieved from the

system before removing any dia-

phragm valve cover.

Loosen the tubing on the Brunermatic

bypass valve #17 Close the inlet and

outlet valves and inspect the Bruner-

matic bypass valve.

If no flow from the tubing the pilot

strainer is probably plugged.

• Seat washer may be dirty, worn or

loose.

• Seat may be rough or eroded.

• Diaphragm may be ruptured.

Check that valve #2 is seating. Build-up on the inside of the valve

cavity may be preventing the dia-

phragm assembly from seating in the

guide cage.

Restricted or No Service Flow Either valves #1 or #4 are not opening

fully. To determine which one, turn the

pilot to position #1. Observe the flow

to the drain. Rotate the pilot to posi-

tion #3 and compare the flow of water

in position #3 to the flow in position

#1. Return the pilot to H (Home).

Flow should be the same for both po-

sitions but if not:

• Valve #4 is not opening properly.

• If backwash (position #1) is higher,

then valve #1 is not responding

properly.

Potentially clogged distributors or

compacted media bed.

Failed distributors.

Contamination of resin bed.

Restricted or No Drain Flow During

Backwash

Turn the pilot to Position #1 and then

to position #3, comparing the rate of

flow to the drain. Return the pilot to H

(Home).

Flow should be the same. If not:

• If the flow in position #3 is low,

see Restricted or No Service Flow

Check Procedures and causes.

• Inlet water pressure may be low.

• Backwash flow control may be

plugged.

• If flow rate in position 3 is greater

than position 1 then valves #2 and

#5 are not functioning properly

Media to Service Check tank distribution system Broken lateral

Bad distributor.

Media to Drain High flow of water to drain. Check/replace backwash flow control

washer(s).

Air in system Brine valve did not air check, allowing

air into media tank.

Air from source other than water soft-

ener. Eliminate source or install air

vent in top of tank.

Leak From End of Pilot Body Visually inspect u-cup and seals on

pilot valve spool.

Worn or pinched u-cup or a scratch on

the pilot valve spool.

Loading...

Loading...