64 Culligan® CSM Series Softeners

64 Cat. No. 01016370

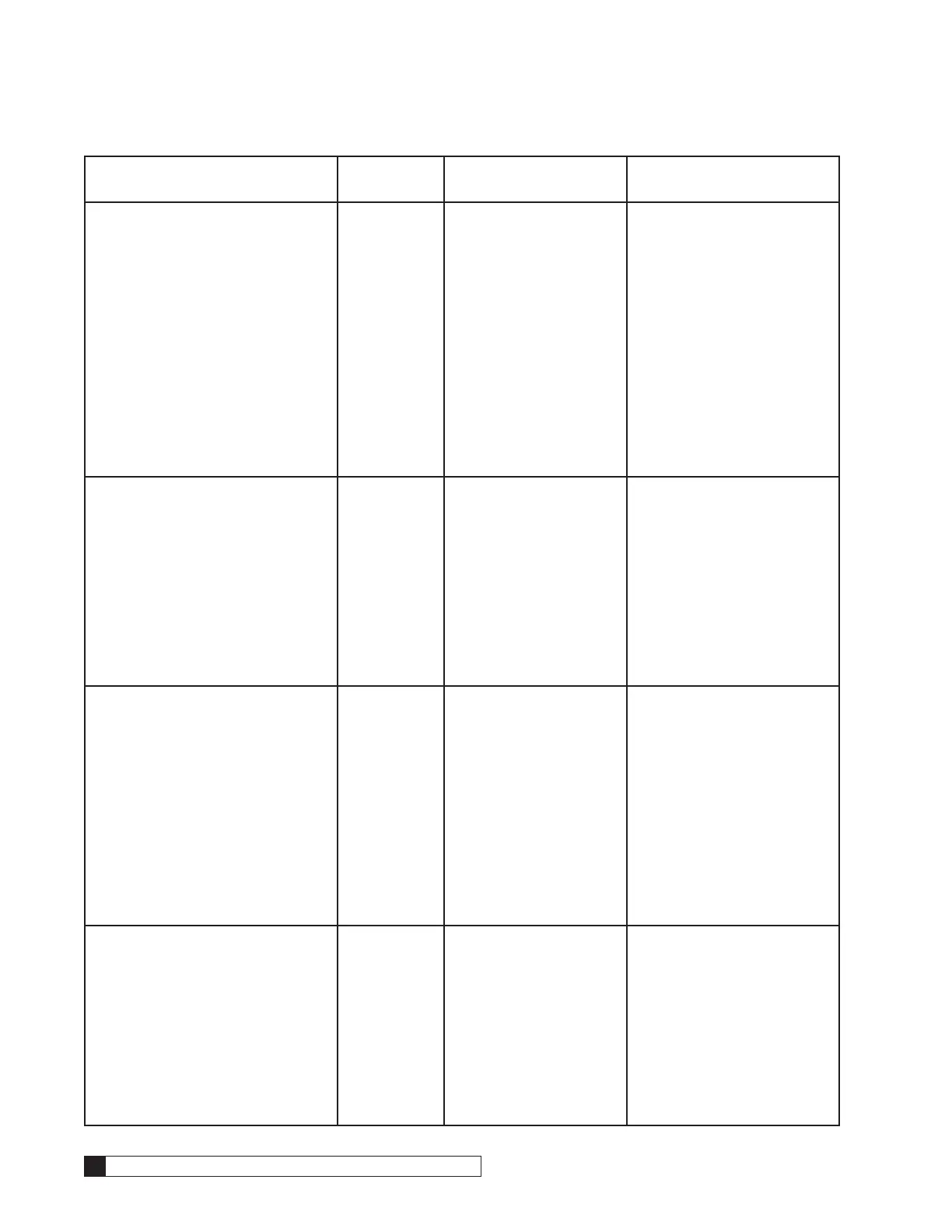

Problem or Symptom Error

Description

Mode of Detection Possible Causes/Rem-

edies

MVP Control Display Error

ERR1

(The control will not function while an

Error is displayed or detected.)

To clear an alarm condition after cor-

rection, press and hold the Status key

for 10 seconds. The control will then

cycle the valve to the home position.

You may also power down the control

for 60 seconds or toggle a DIP switch.

If the problem is still present after at-

tempting to clear the error code, the

code will remain in the display.

Motor Failure

to Start

The error will occur if the

valve fails to reach the

desired state within 2 min-

utes of driving the motor.

The control will attempt to

start the motor 3 times for

2 minutes each time with

a 60-second off period be-

tween each attempt.The

control will power down

all triacs until the problem

is corrected. The con-

trol beeper will sound 3

times per second every 30

seconds until any key is

pressed.

1. Poor motor - Replace

2. Bad Cam - Inspect/Replace.

3. Bad/loose wiring-Inspect/

Repair.

4. Problem with MVP cir-

cuit board - run Test program

to verify operation of board

components.

5. Pilot spool is bound, prohibit-

ing motor from moving-Inspect/

Repair.

6. Micro-switches not function-

ing/sticking -Inspect/Replace.

MVP Control Display Error

ERR2

To clear an alarm condition after cor-

rection, press and hold the Status key

for 10 seconds. The control will then

cycle the valve to the home position.

You may also power down the control

for 60 seconds or toggle a DIP switch.

If the problem is still present after at-

tempting to clear the error code, the

code will remain in the display.

Motor Failure

to Stop

If the control detects

changes in the cam inputs

when the motor is not sup-

posed to be turning.

1. Poor motor - Replace

2. Problem with MVP cir-

cuit board - run Test program

to verify operation of board

components.

3. Micro-switches not function-

ing/sticking -Inspect/Replace.

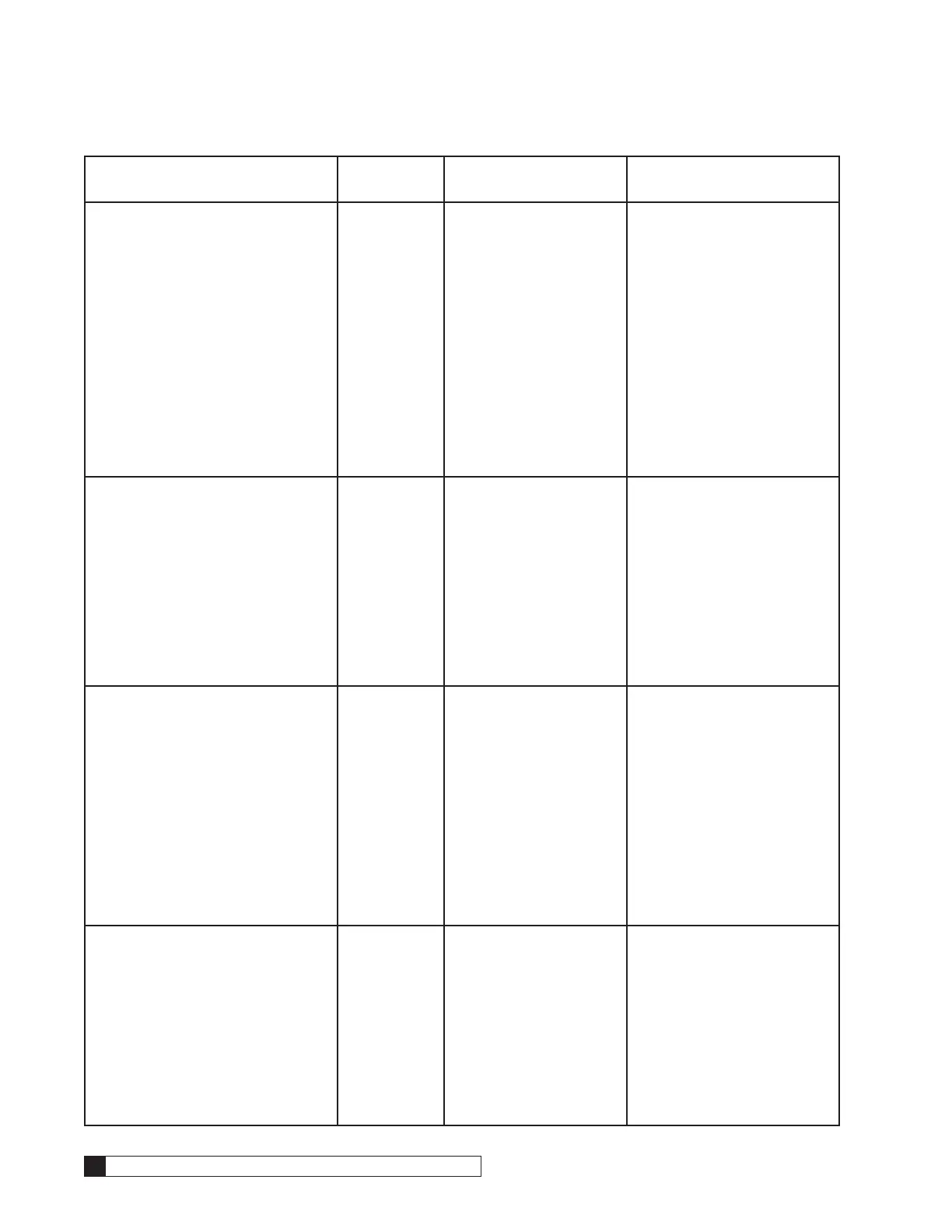

MVP Control Display Error

ERR3

To clear an alarm condition after cor-

rection, press and hold the Status key

for 10 seconds. The control will then

cycle the valve to the home position.

You may also power down the control

for 60 seconds or toggle a DIP switch.

If the problem is still present after at-

tempting to clear the error code, the

code will remain in the display.

Incorrect Cycle

Position

The control expects to be

in a different position than

that indicated by the cam

switch closures.

1. Poor motor - Replace

2. Bad Cam - Inspect/Replace.

3. Bad/loose wiring - Inspect/

Repair.

4. Problem with MVP cir-

cuit board - run Test program

to verify operation of board

components.

5. Pilot spool is bound, pro-

hibiting motor from moving.

- Inspect/Repair.

6. Micro-switches not function-

ing/sticking -Inspect/Replace.

MVP Control Display Error

ERR4

To clear an alarm condition after cor-

rection, press and hold the Status key

for 10 seconds. The control will then

cycle the valve to the home position.

You may also power down the control

for 60 seconds or toggle a DIP switch.

If the problem is still present after at-

tempting to clear the error code, the

code will remain in the display.

Units Have the

Same ID

The error occurs when

multiple units are con-

nected and an ID number

is shared between multiple

controls.

Refer to page 39 and the sec-

tion on Multiple Unit Communi-

cation Setup and re-establish

ID’s.

Diagnostics 64

Loading...

Loading...