Troubleshooting 57

Cat. No. 01029343

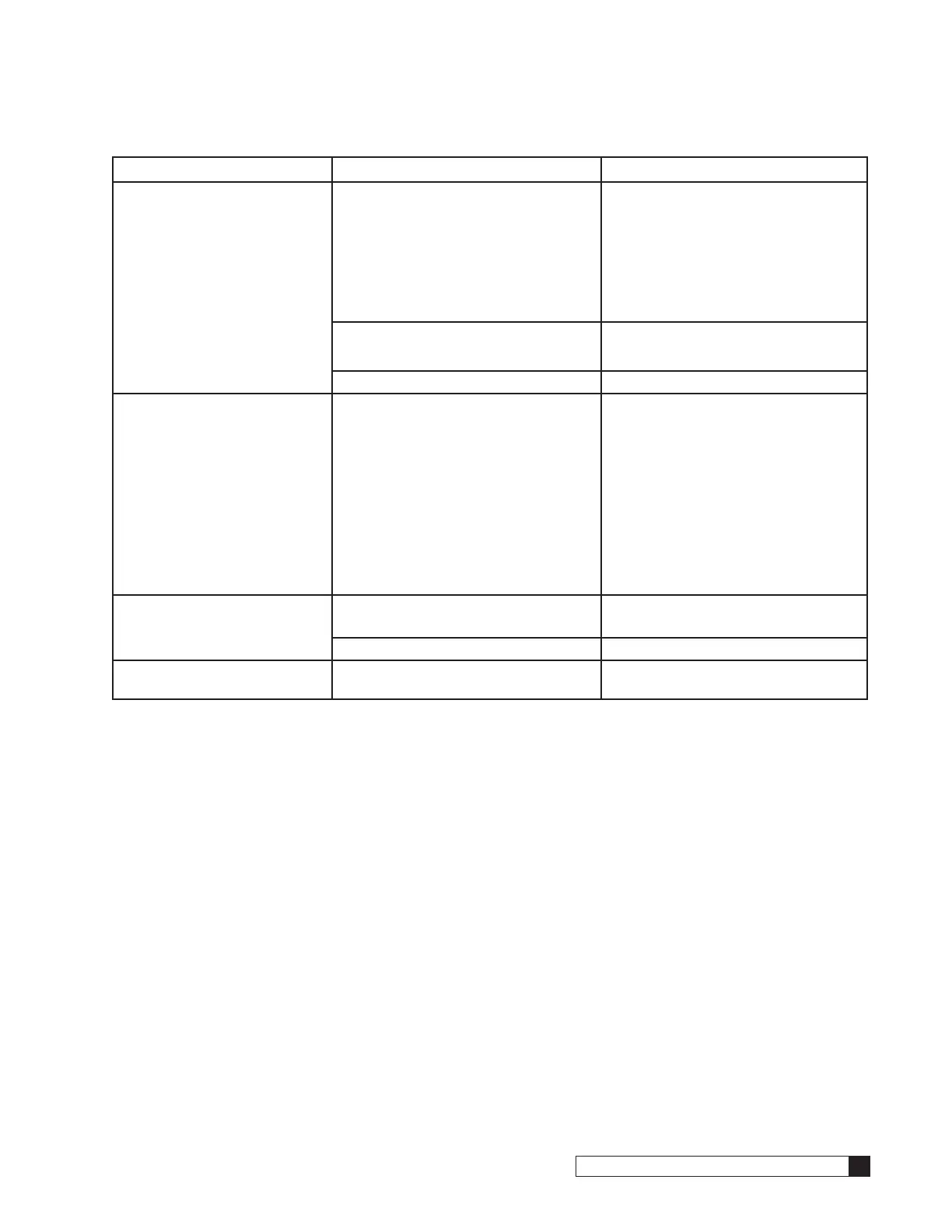

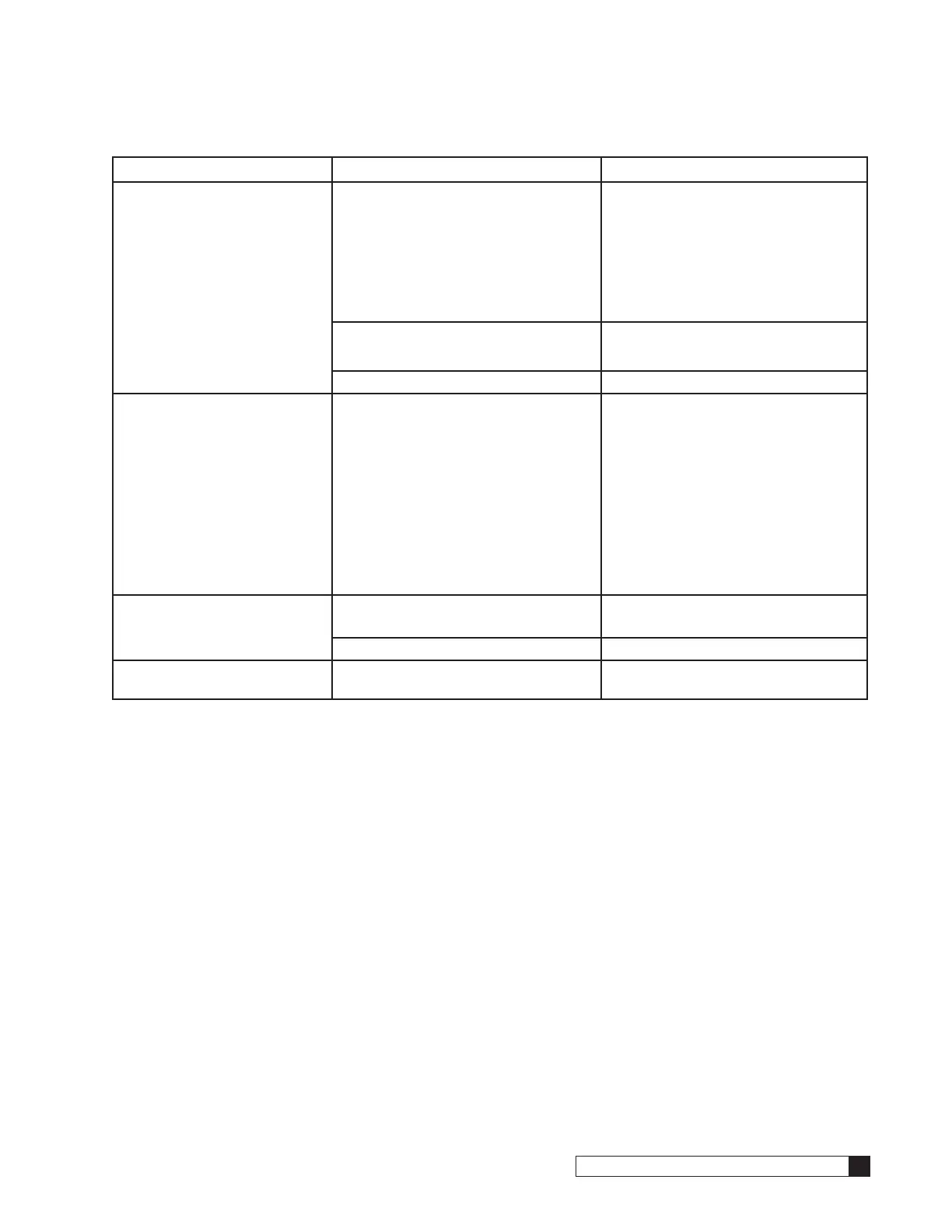

PROBLEM OR SYMPTOM CHECK PROCEDURE CAUSE

Restricted or No Service Flow Either Service Inlet piston or Service

Outlet piston are not opening fully. To

determine which one, turn the pilot to po-

sition #2. Observe the flow to the drain.

Cycle the pilot to position #4 and com-

pare the flow of water in position #4 to

the flow in position #2. Return the pilot to

position #1.

Flow should be the same for both posi-

tions but if not:

• Service Outlet piston is not opening

properly.

• If backwash (position #2) is high-

er, then Service Inlet piston is not

responding properly.

Potentially clogged distributors or com-

pacted media bed.

Failed distributors.

Contamination of resin bed.

Check feed water pressure Water pressure is less than 35 psi.

Restricted or No Drain Flow

During Backwash

Turn the pilot to position #2 and then to

position #4, comparing the rate of flow to

the drain. Return the pilot to position #1.

Flow should be the same. If not:

• If the flow in position #4 is low, see

Restricted or No Service Flow Check

Procedures and causes.

• Inlet water pressure may be low.

• Backwash flow control may be

plugged.

• If flow rate in position #4 is greater

than position #2 then Backwash Inlet

piston and Backwash Drain piston

are not functioning properly

Media to Service Check tank distribution system Broken lateral

Bad distributor.

Trace and examine the plumbing Unit is plumbed backwards

Media to Drain High flow of water to drain. Check/replace backwash flow control

washer(s).

Loading...

Loading...