56 Culligan® Culligan Top Mount (CTM) Water Filters

56 Cat. No. 01029343

Troubleshooting

Drain Line Flow Control—Service

Located on the drain connection of the valve, the purpose of the backwash flow controller is to regulate the up flow back-

wash required to expand and agitate the media in the filter. The filter will allow maximum expansion of the media, while

preventing any loss to the drain.

The flow control principle is simple and trouble free. The specified rate of flow will be constant regardless of inlet pressure

variations.

Occasionally, the Backwash Flow Controller may become plugged with scale, rust, or other foreign material. If this occurs,

cleaning is required. This can be done while the filter is in SERVICE and under pressure.

General Troubleshooting

NOTE Error Codes can be found in the GBE Programming for Commercial Softeners and Filters manual

(01027295)

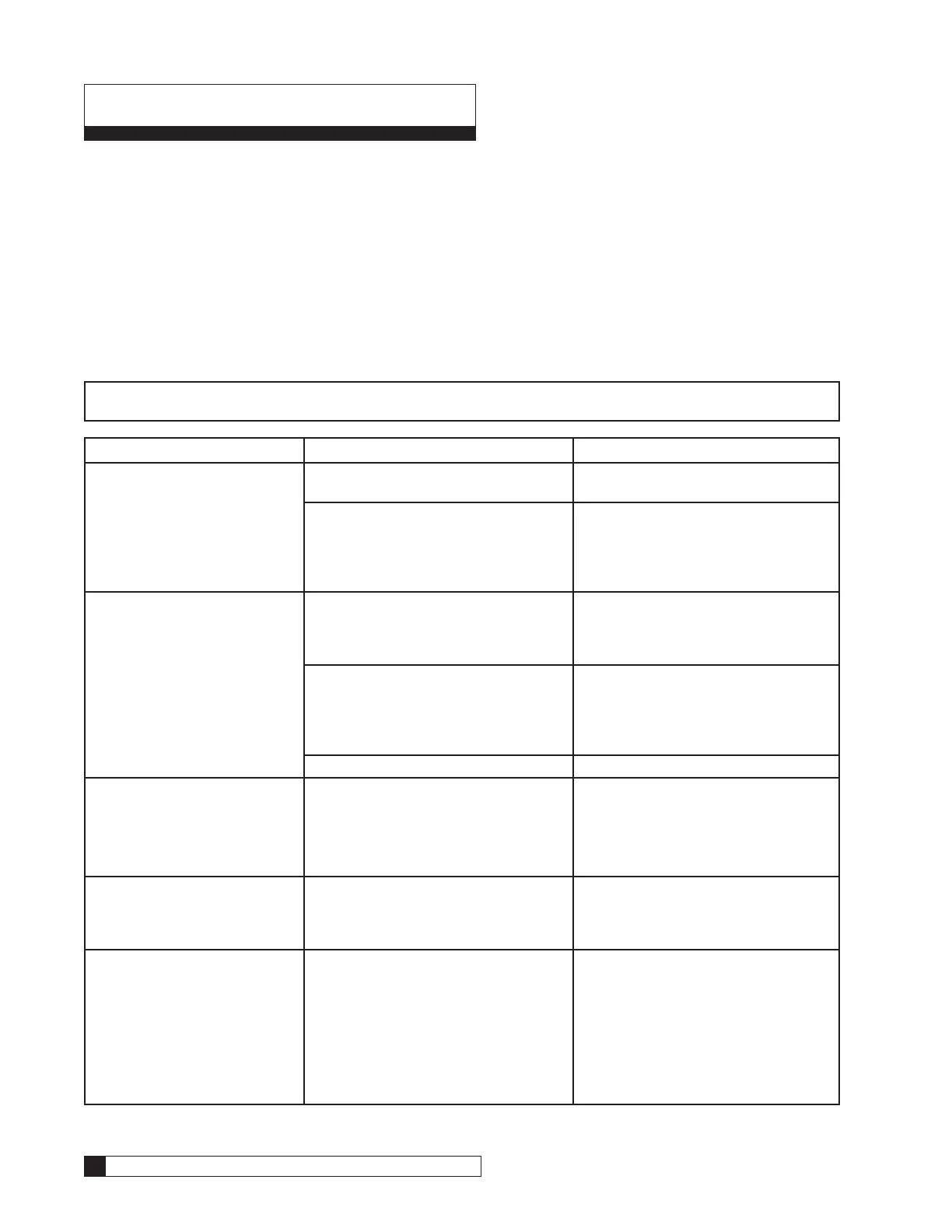

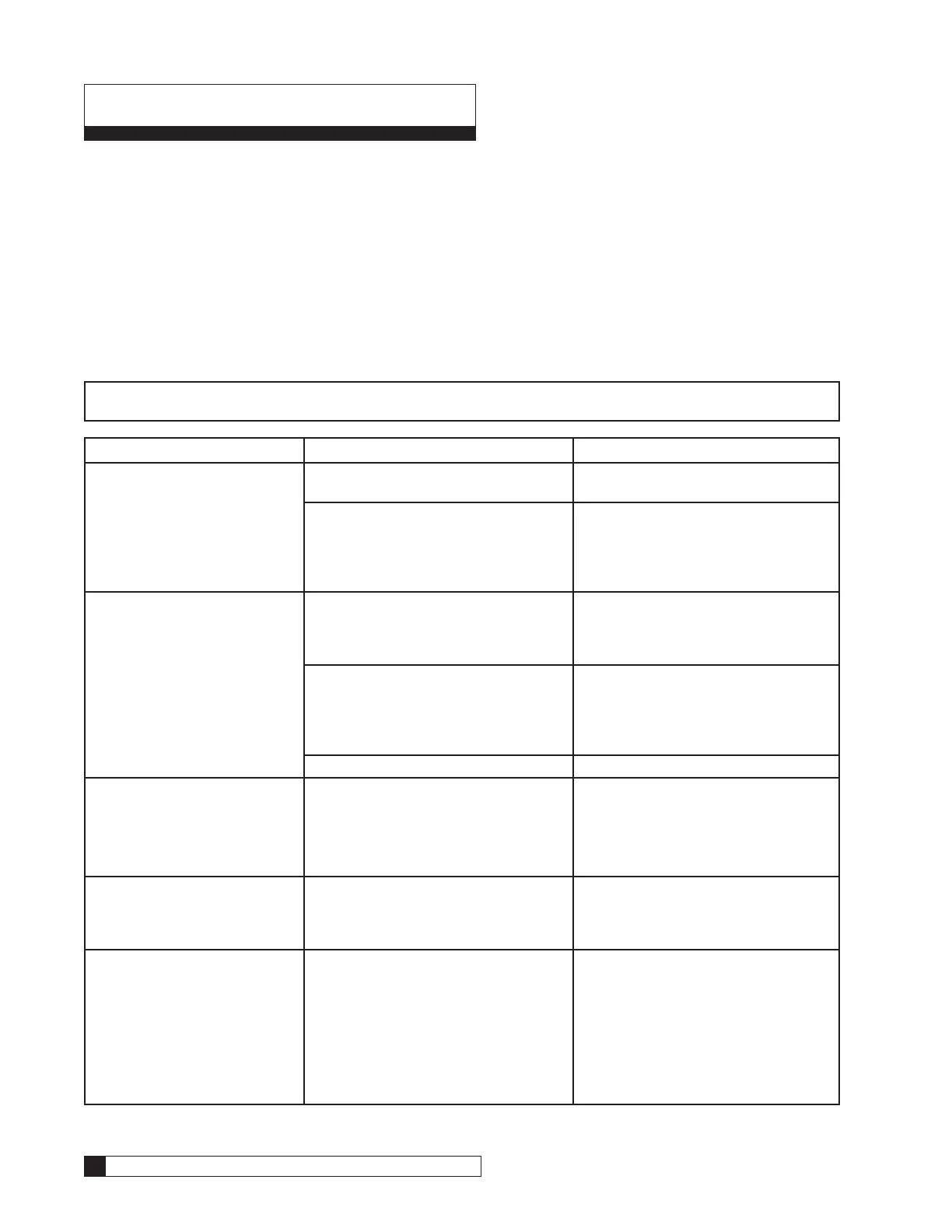

PROBLEM OR SYMPTOM CHECK PROCEDURE CAUSE

Slight Leak to Drain Disconnect pilot valve tubing at drain port

on the valve.

Flow from tubing indicates leaky seal in

pilot valve spool.

If pilot valve is not leaking, use a test kit

and check for hard water at the drain.

Possible missing or damage piston/cap

O-Rings or T-Seal. If water tests soft

then fast rinse drain piston is open. If the

water tests hard then backwash drain

piston is open.

High Flow to Drain During

Service

Check position dial pilot. If not in Position #1, manually cycle

the pilot drive assembly to Position #1.

If the flow stops, check the pilot drive

assembly.

Use a test kit and check the hardness of

the water at the drain.

Use a test kit and check the hardness

of the water at the drain. If soft then fast

rinse drain piston is open. If the water

tests hard then backwash drain piston is

open.

Check the feed water pressure Water pressure is less than 35 psi.

Piston Does Not Close or Open.

CAUTION: make certain that

the water pressure is relieved

from the system before remov-

ing the spool manifold.

Turn off the water pressure, remove

spool manifold, then remove piston from

control valve.

If there is no flow from the tubing, the pi-

lot strainer may be plugged.

• T-Seal may be dirty, worn or loose.

• Seat may be eroded.

• Upper piston o-ring may be torn.

Piston Does Not Open Turn off the water pressure, remove

clamp, remove external plumbing con-

nections then remove valve body from

tank adapter. Visually inspect T-Seal.

T-Seal may be fouled or swollen.

Unfiltered Water Leakage Into

the Service Lines.

CAUTION: make certain that

the water pressure is relieved

from the system before dissas-

sembling the control valve.

Inspect the bypass piston. If no flow from the tubing the pilot strain-

er is probably plugged.

• T-Seal may be dirty, worn or loose.

• Seat may be eroded.

• Upper piston o-ring may be torn.

Build-up on the inside of the valve cavity

may be preventing the piston assembly

from seating.

Loading...

Loading...