3 Immerse nozzle needle and nozzle body in

clean diesel oil and check slide ability by

means of drop test.

DROP TEST

Keep nozzle body vertical, pull out the needle

to one- third of its length. It must drop back

on its seat by its own weight slowly. If the

needle does not slide in body, smear a little

mutton allow on it and lap the needle in

nozzle body. Do lapping in back and forth

and rotary movement of needle in nozzle

body. While doing so, the nozzle needle seat

should not touch the seat in nozzle body.

Wash in diesel and recheck by drop test.

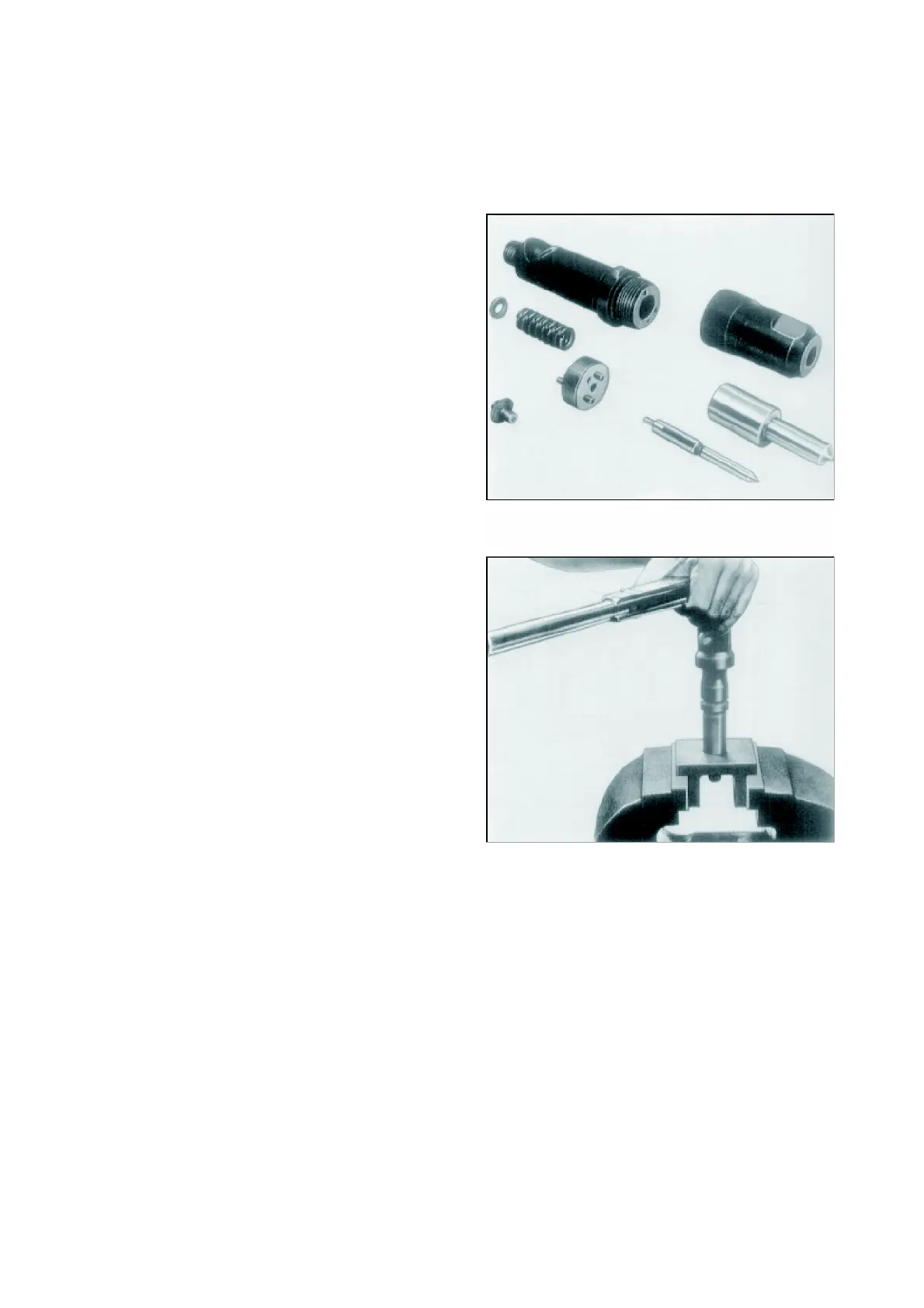

4. Assemble nozzle in the sequence as shown

into the nozzle holder taking care to match

the locating pins on intermediate disc and

screw on pressure screw. Fig. 25

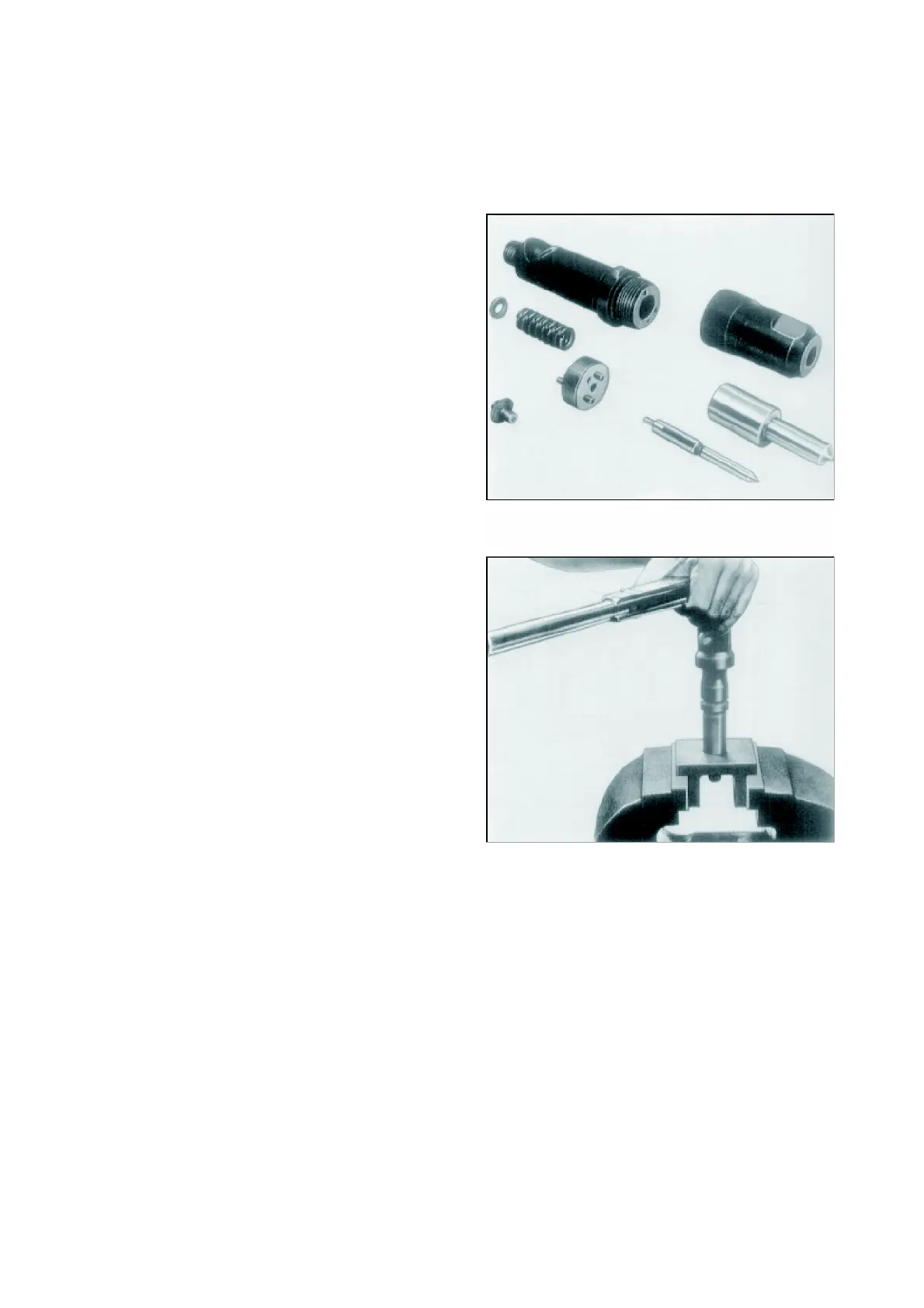

5. Place nozzle holder into holder 403 589 00

31 00.

6. Tighten pressure nut with special wrench 000

589 01 13 00 to specified torque. Fig. 26.

Mark injection pump by the letter “Z” behind the

pump designation after the work has been carried

out.

Fig. 26

Fig. 25

Fig. 27

Workshop Manual

S3.8 Engine

A030K288 (Issue 2)

01-2010

Loading...

Loading...