4 — PROGRAMMABLE PARAMETERS

Curtis AC F4-A Motor Controller – August 2020 Return to TOC

pg. 58

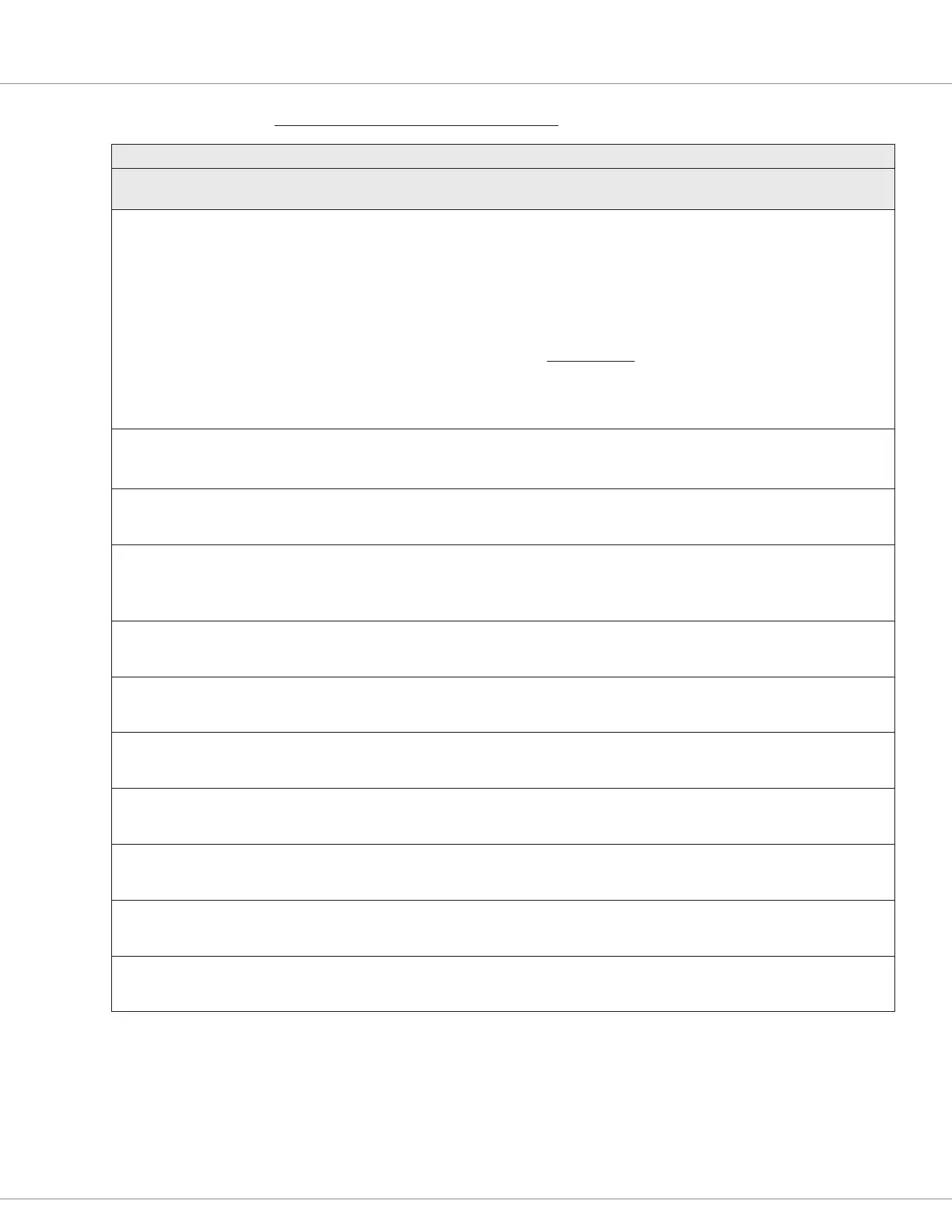

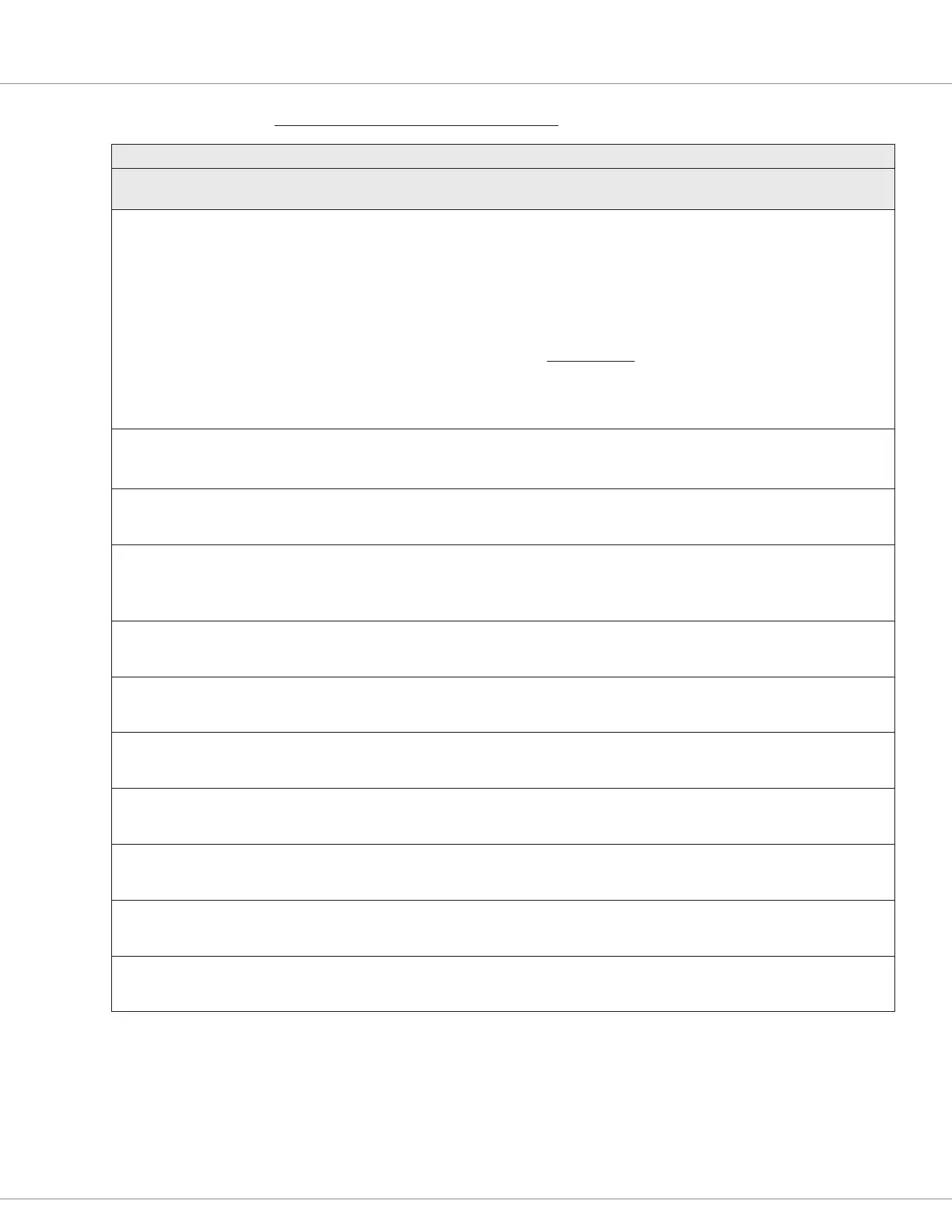

APPLICATION SETUP/CAN INTERFACE — PDO SETUPS MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

RPDO1 Note: PDO transmissions are from the perspective of the ancillary controller

RPDOs are messages received by the ancillary (i.e., send from the manager)

Timeout

can_rpdo_1_event_timer

0x1400 0x05

0 – 65535

0 – 65535

40 ms Sets the PDO timeout period for the CANopen Ancillary system.

After the ancillary controller has sent a TPDO (PDO-TX), it will

declare a PDO Timeout Fault if the manager controller has not

sent a reply RPDO (PDO-RX) message within the time set by this

parameter. Any RPDO1-4 will reset the timer.

Setting this parameter to zero (Timeout = 0) disables the PDO

timeout fault check.

See Appendix A for PDO mapping/setup.

Application Note: Based upon the F-series cdev revision, this

timer may begin as soon as the controller goes operational (NMT

= 5), and not upon the first RPDO message received. Check this

aspect using a CANbus trace if unexpected PDO Timeout errors

occur.

COB ID

can_rpdo_1_cob_id

0x1400 0x01

0 – 0xFFFFFFFF

0 – 42949672295

80000226h The application’s 11-bit COB-ID (Communication Object ID).

Note: Use VCL for 29-bit COB ID.

See Appendix A.

Length

can_rpdo_1_length

0x1600 0x00

0 – 8

0 – 8

0 Number of CAN objects in map (not the number of bits or bytes).

See Appendix A.

1

can_rpdo_1_map_1

0x1600 0x01

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 1

st

object variable and bit length (8,16, 24, or 32).

See Appendix A.

The default value, 0x00050008 is a dummy 8-bit PDO variable (as

per CANopen).

2

can_rpdo_1_map_2

0x1600 0x02

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 2

nd

object variable and bit length (8, 16, 24, or 32).

See Appendix A.

3

can_rpdo_1_map_3

0x1600 0x03

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 3

rd

object variable and bit length (8, 16, 24, or 32).

See Appendix A.

4

can_rpdo_1_map_4

0x1600 0x04

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 4

th

object variable and bit length (8, 16, 24, or 32).

See Appendix A.

5

can_rpdo_1_map_5

0x1600 0x05

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 5

th

object variable and bit length (8, 16, 24, or 32).

See Appendix A.

6

can_rpdo_1_map_6

0x1600 0x06

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 6

th

object variable and bit length (8, 16, 24, or 32).

See Appendix A.

7

can_rpdo_1_map_7

0x1600 0x07

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 7

th

object variable and bit length (8, 16, 24, or 32).

See Appendix A.

8

can_rpdo_1_map_8

0x1600 0x08

0h – FFFFFFFFh

0 – 4294967295

0x00050008

327688

Map 8

th

object variable and bit length (8, 16, 24, or 32).

See Appendix A.

Quick Link:

Appendix A p.184

Loading...

Loading...