G420E/G424E Tier LP Engine Maintenance Schedule 33

Testing Fuel Lock-off

Operation

z Start engine.

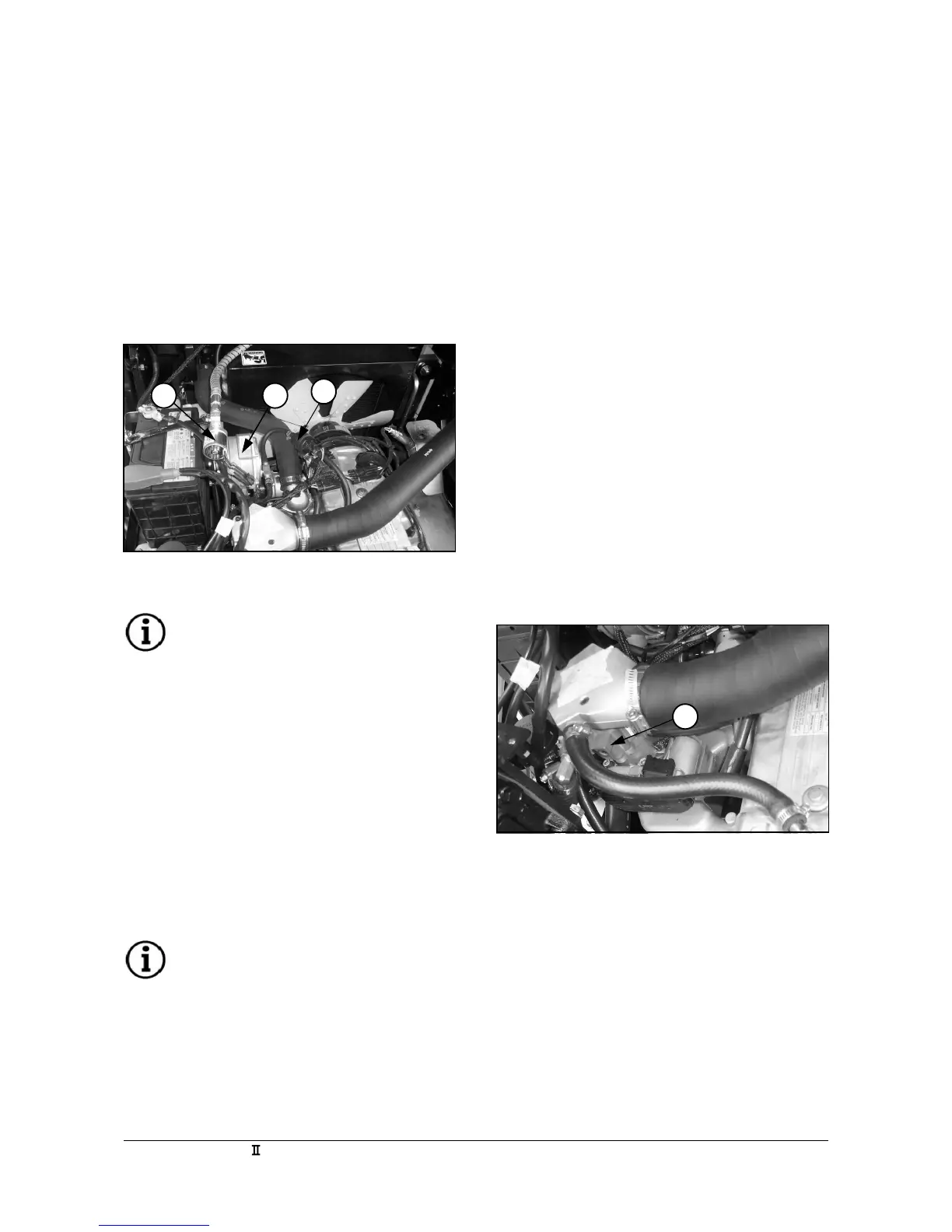

z Locate the electrical connector for the fuel lock

(A).

z Disconnect the electrical connector.

z The engine should run out of fuel and stop within

a short period of time.

z Turn the ignition key switch off and re-connect

the fuel lock-off connector.

(A) LP fuel lock-off (B) LP regulator/converter

(C) Fuel Trim Valve

NOTE

The length of time the engine runs on

trapped fuel vapor increases with any

increase in distance between the fuel

lock-off and the pressure

regulator/converter.

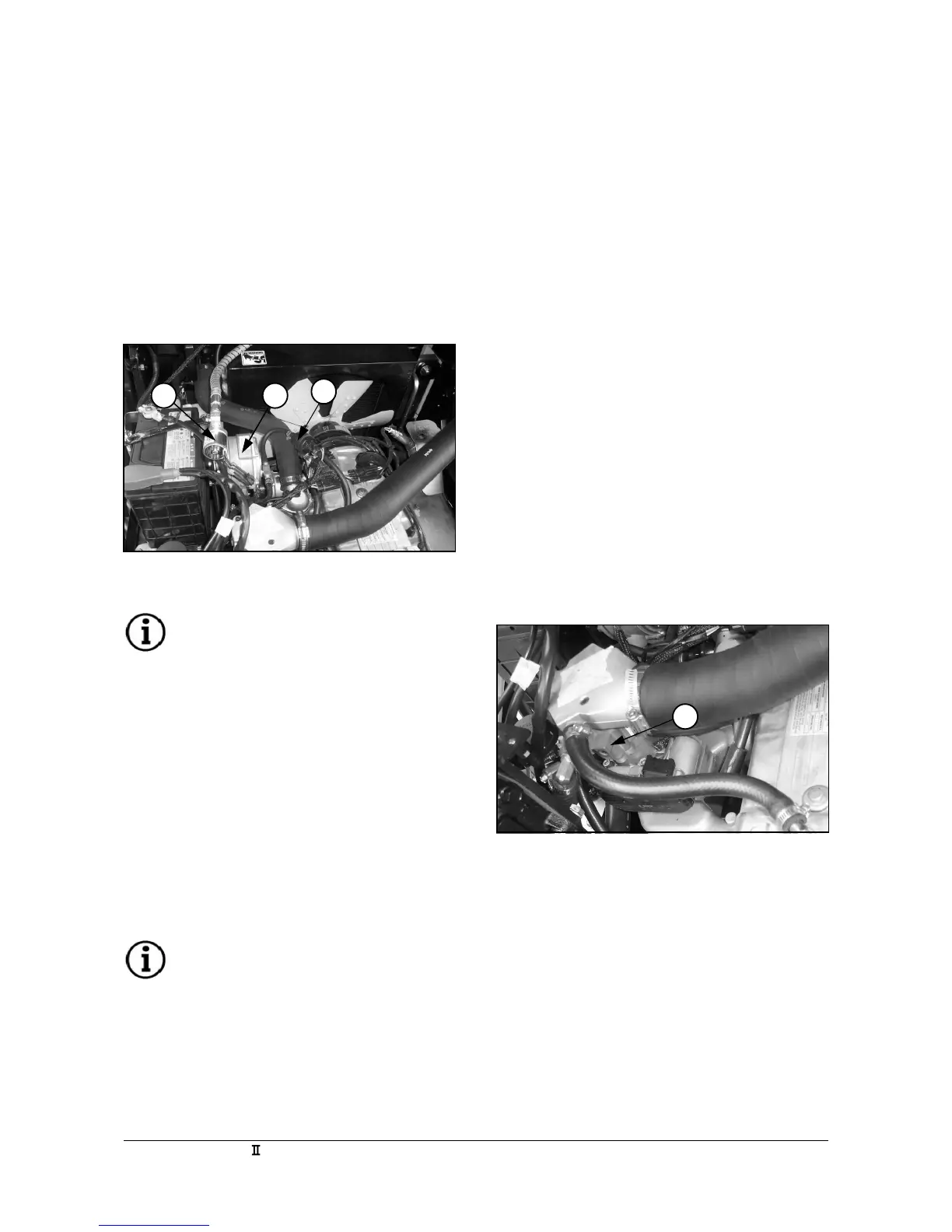

Pressure

Regulator/Converter Testing

and Inspection

z Visually inspect the pressure regulator/converter

(B) housing for coolant leaks. Refer to the

pressure regulator/converter section of the

service manual if maintenance is required.

NOTE

For pressure testing and internal

inspection of the pressure

regulator/converter, refer to the pressure

regulator/converter section of the service

manual.

Fuel Trim Valve Inspection

(FTV)

z Visually inspect the Fuel trim valve (C) for

abrasions or cracking. Replace as necessary.

z To ensure the valve is not leaking a blow-by test

can be performed.

1. With the engine off, disconnect the electrical

connector to the FTV.

2. Disconnect the vacuum line from the FTV to the

pressure regulator/converter, at the converter’s

tee connection.

3. Lightly blow through the vacuum line connected to

the FTV. Air should not pass through the FTV

when de-energized. If air leaks past the FTV when

de-energized replace the FTV.

Inspect Air/Fuel Valve Mixer

Assembly

Refer to the LP mixer (G) section of the service

manual for procedures.

(G) LP mixer

Loading...

Loading...