©

200423 3-19

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

ΞΦ95 series

5

3.23 INSPECTING THE AUTOMATIC BRAKE ADJUSTER

Brake drum

Inspection, brake adjuster travel

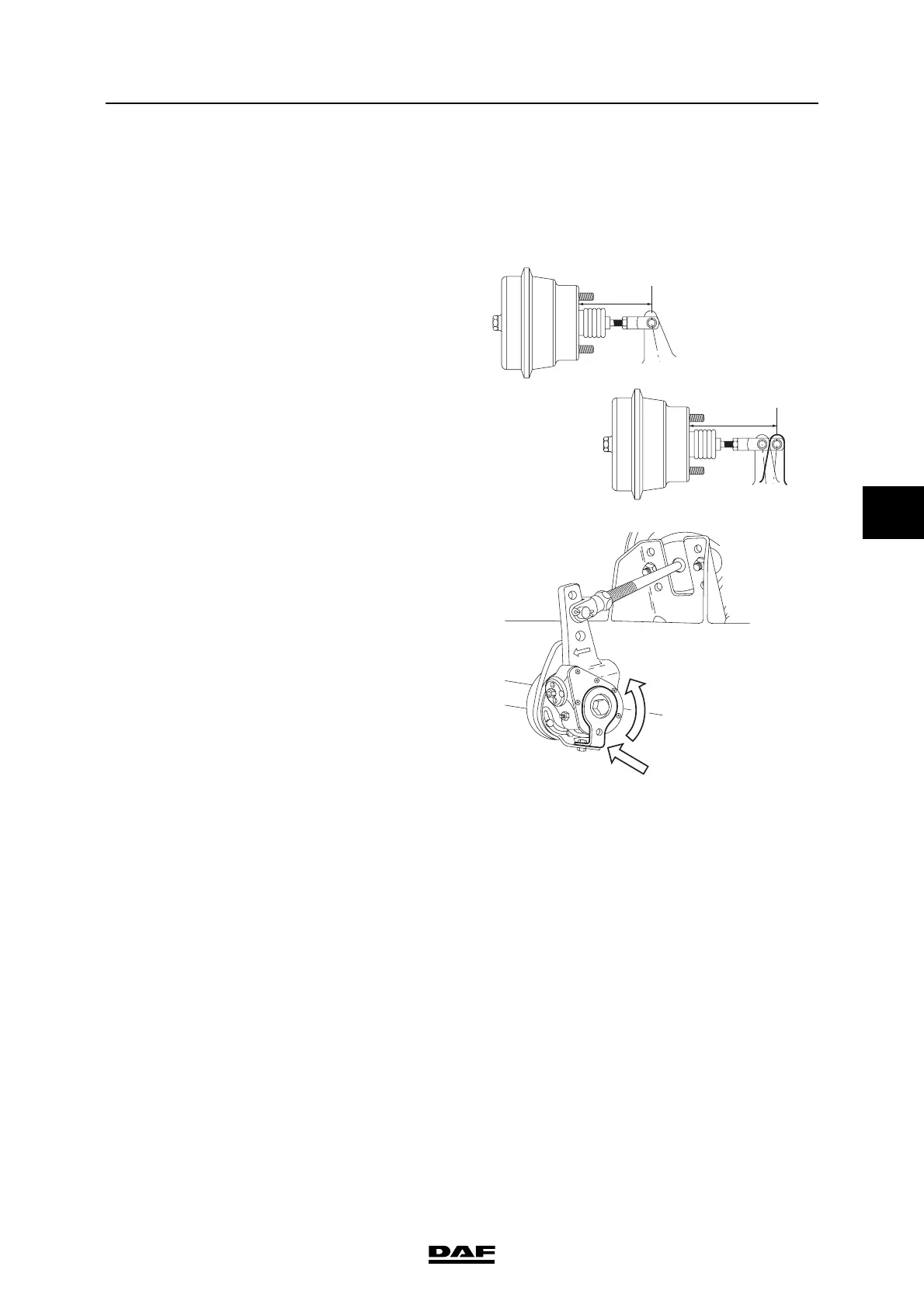

1. Measure the basic setting L1.

2. Measure the position when the brakes are

applied, L2 (minimum brake system

pressure 6 bar).

3. Calculate the brake stroke L3 = L2 - L1, see

"Technical data". If the brake stroke differs

from the specified value, take the following

action:

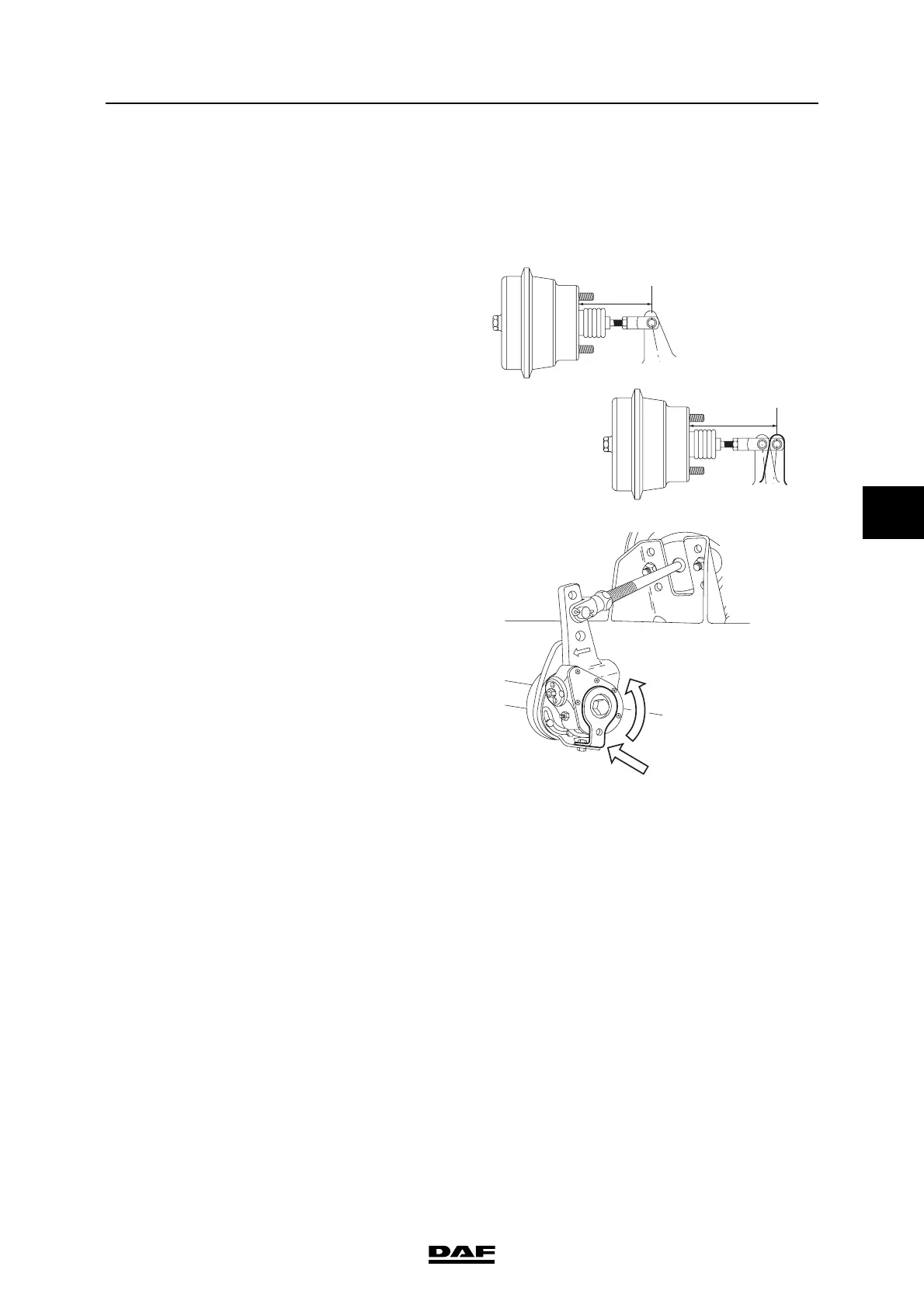

4. Check whether the control plate (1) is locked

in respect of the fixed bracket.

5. If not, turn the control plate as far as possible

(until the internal stop is felt) in the direction

in which the brake adjuster is moved during

braking.

6. Fix the control plate in this position using the

attachment nut on the fixed bracket.

7. Check the internal slip using a torque

wrench.

Inspection, internal slip

1. Make certain that there is sufficient pressure

in the reservoirs (6.5 bar minimum).

2. Release the parking brake.

3. Fit a torque wrench on the hexagonal

adjusting bolt and turn this counter-

clockwise. For the permitted value, see

"Technical data".

If the specified reverse torque is not

reached, but the worm shaft already turns at

a lower value, the brake adjuster should be

replaced.

M6101

L2

L1

M6005

1

Loading...

Loading...