opTIonal loW ambIenT fan Vfd

www.DaikinApplied.com 91 IOM 1206-7 • TRAILBLAZER

™

MODEL AGZ CHILLERS

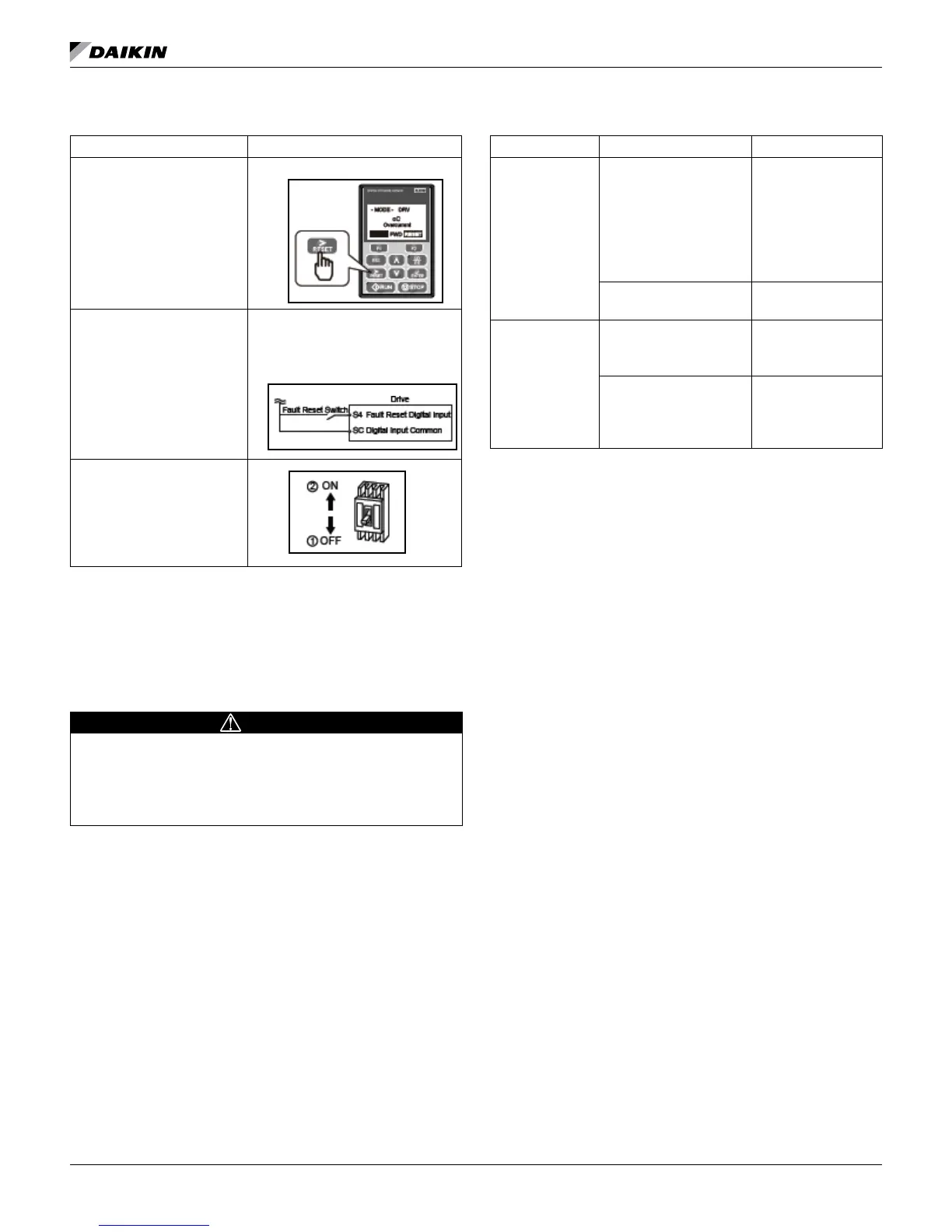

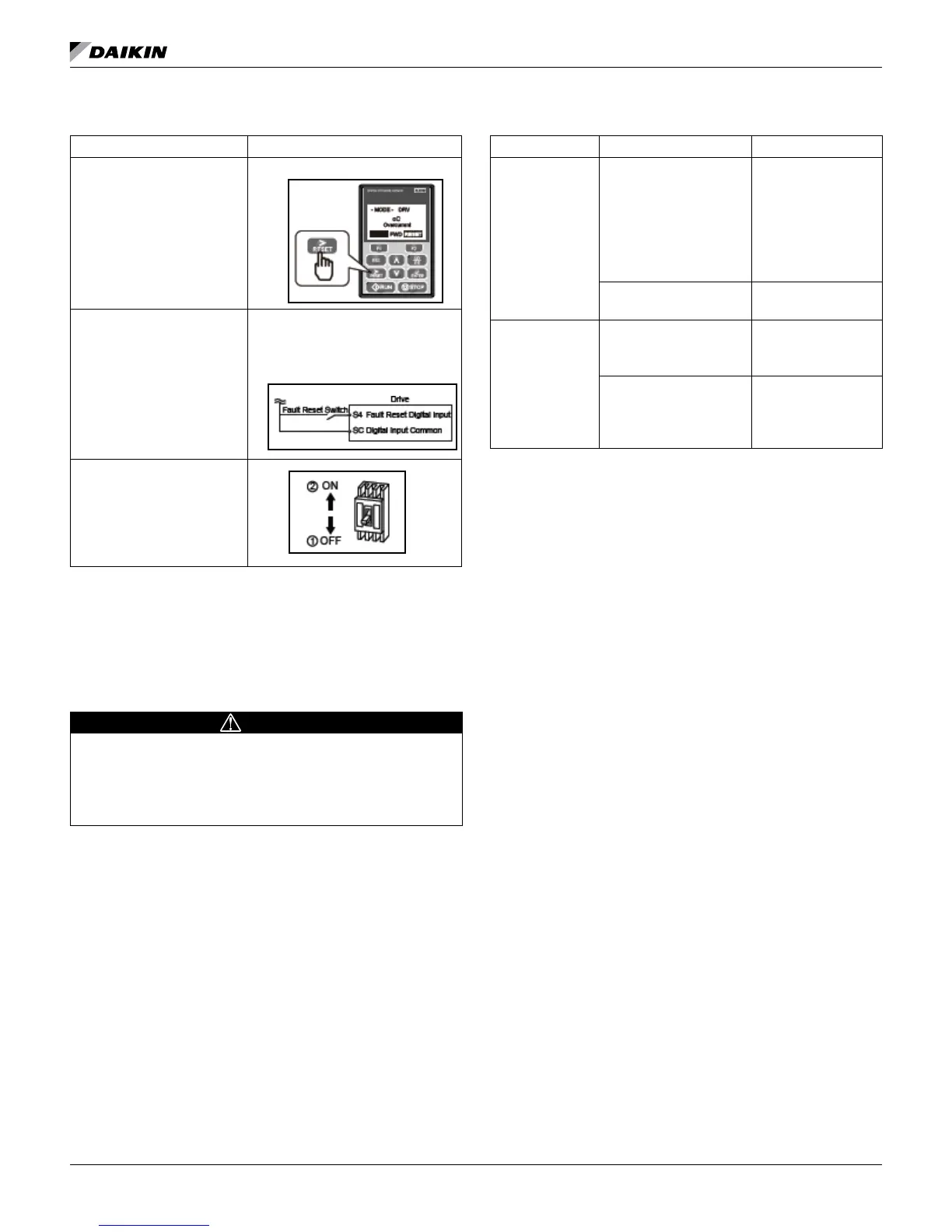

Table 84: Fault Reset Methods

After the Fault Occurs Procedure

Fix the cause of the fault,

restart the drive, and reset

the fault

Press RESET on the controller.

Resetting via Fault Reset

Digital Input S4

Close then open the fault signal

digital input via terminal S4. S4 is

set for “Fault Reset” as default

(H1-04 = 14)

Turn off the main power

supply if the above methods

do not reset the fault.

Reapply power after the

controller display has turned

off.

NOTE: When a fault occurs, the cause of the fault must

be removed and the drive must be restarted. The

above table list the various ways to restart the drive.

Remove the Run command before attempting to clear

a fault. If the Run command is present, the control will

disregard any attempt to reset the fault.

Recommended Periodic Inspection

WARNING

Electrical Shock Hazard. Before servicing or inspecting

the equipment, disconnect power to the unit.The internal

capacitor remains charged after power is turned off. Wait

at least the amount of time specied on the drive before

touching any components.

Table 85: Periodic Inspection Checklist

Inspection Area Inspection Points Corrective Action

General

Inspect equipment

including wiring,

terminals, resistors,

capacitors, diode and

IGBT for discoloration

from overheating or

deterioration.

Replace damaged

components.

Inspect for dirt or foreign

particles

Use dry air to clear

away.

Relays and

Contactors

Inspect contactors and

relays for excessive

noise.

Check for over or

undervoltage

Inspect for signs of

overheating such as

melted or cracked

insulation

Replace damaged

parts.

Optional BAS Interface

The AGZ chiller controller is congured for stand-alone

operation or integration with BAS through an optional

communication module.

The following installation manuals for optional BAS interface

modules are shipped with the chiller. They can also be found

and downloaded from www.DaikinApplied.com.

• IM 966-1, BACnet

®

IP Communication Module

• IM 967-1, BACnet

®

Communication Module (MS/TP)

• IM 968-1, LONWORKS Communication Module

• IM 969-2, Modbus

®

Communication Module

• ED 15120, Protocol Information for MicroTech

®

III chiller,

BACnet and LONWORKS

• ED 15121, Protocol Information for MicroTech

®

III chiller,

Modbus

For specic information on the installation and operation of

the Intelligent Equipment

®

platform for Trailblazer chillers

please refer to OM 1241 - Intelligent Equipment

®

Operation

and Maintenance Manual for Trailblazer

®

Chillers or IM 1240

Intelligent Equipment

®

Installation Manual for Trailblazer

®

Chillers.

Loading...

Loading...