unit installation

www.DaikinApplied.com 13 IM 1049-9

Cleaning & Flushing System

1. Priortorstoperationofanyconditioner,thewater

circulatingsystemmustbecleanedandushedofall

construction dirt and debris.

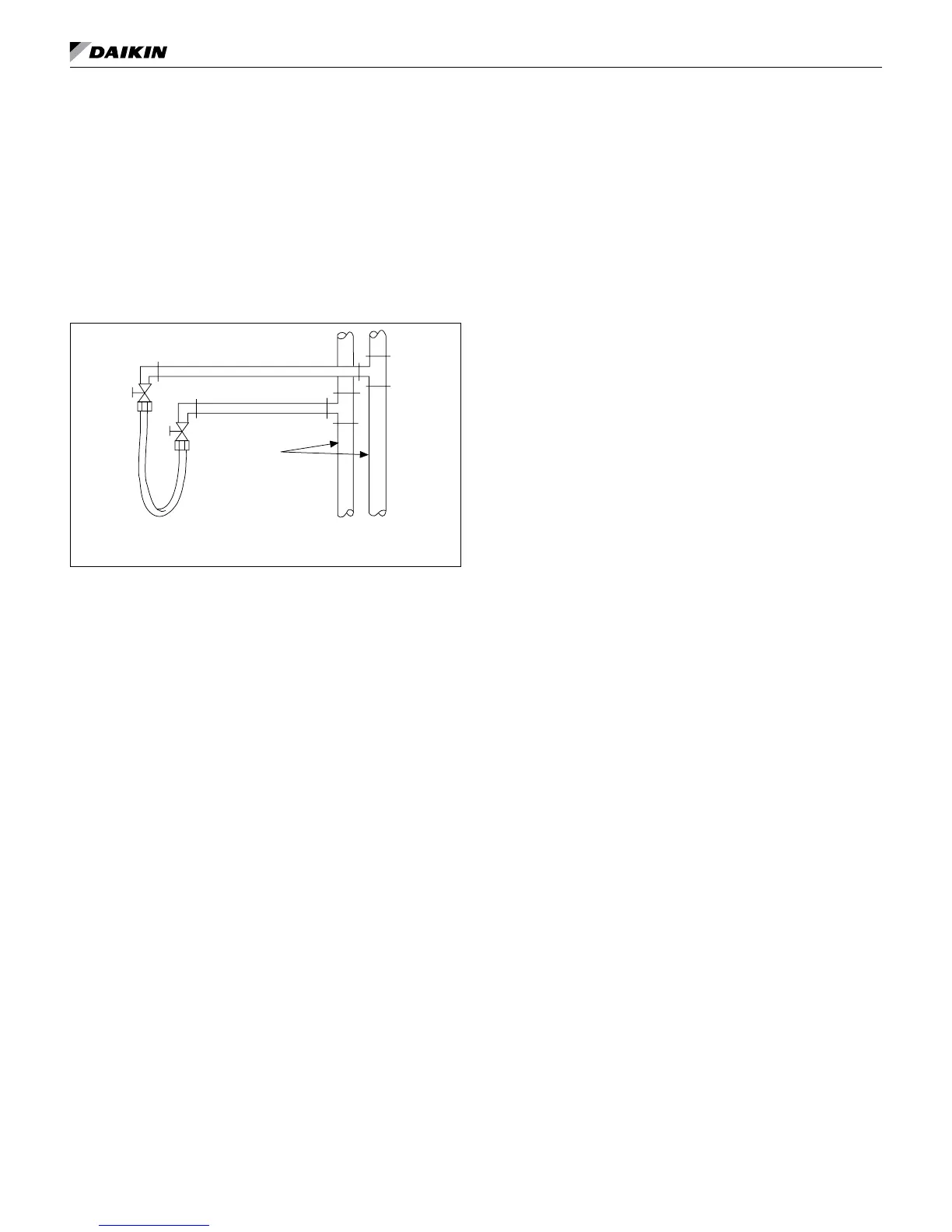

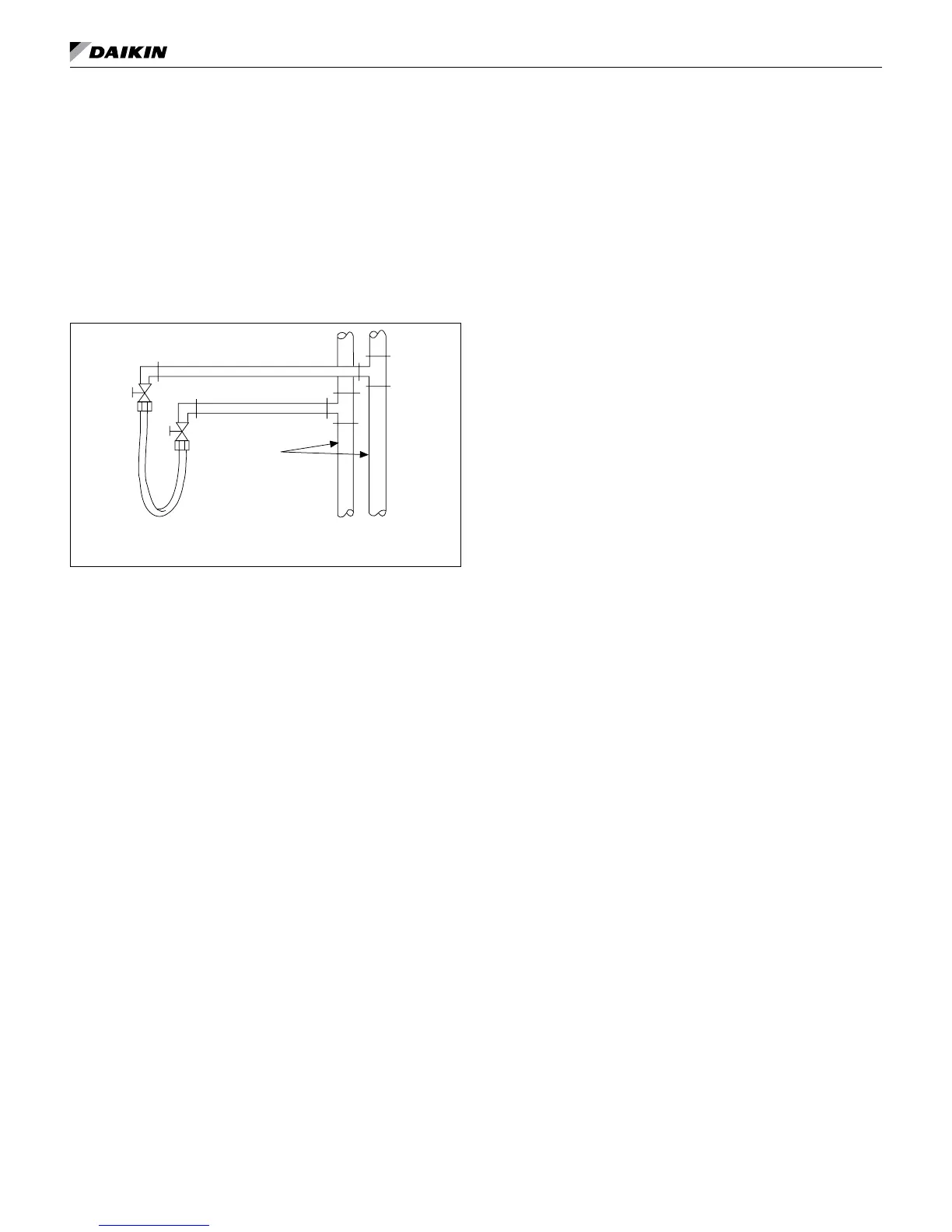

If the conditioners are equipped with water shutoff

valves, either electric or pressure operated, the supply

and return runouts must be connected together

at each conditioner location. This will prevent the

introduction of dirt into the unit. See Figure 13.

Figure 13: Supply & return runouts connected together

Return Runout

Supply Runout

Mains

Flexible

Hose

Runouts Initially

Connected Together

2. Fill the system at the city water makeup connection

withallairventsopen.Afterlling,closeallairvents.

The contractor should start main circulator with

the pressure reducing valve open. Check vents

in sequence to bleed off any trapped air, ensuring

circulation through all components of the system.

Power to the heat rejector unit should be off, and

the supplementary heat control set at 80°F (27°C).

While circulating water, the contractor should check

and repair any leaks in the piping. Drains at the

lowest point(s) in the system should be opened for

initialushandblowdown,makingsurecitywater

llvalvesaresettomakeupwateratthesame

rate. Check the pressure gauge at pump suction

and manually adjust the makeup to hold the same

positive steady pressure both before and after

opening the drain valves. Flush should continue for

at least two hours, or longer if required, to see clear,

clean drain water.

3. Shut off supplemental heater and circulator pump

and open all drains and vents to completely drain

down the system. Short circuited supply and return

runouts should now be connected to the conditioner

supply and return connections. Do not use sealers

attheswivelareconnectionsofhoses.

4. Trisodium phosphate was formerly recommended

asacleaningagentduringushing.However,

many states and localities ban the introduction of

phosphates into their sewage systems. The current

recommendationistosimplyushlongerwithwarm

80°F (27°C) water.

5. Rellthesystemwithcleanwater.Testthewater

using litmus paper for acidity, and treat as required

to leave the water slightly alkaline (pH 7.5 to 8.5).

Thespeciedpercentageofantifreezemayalsobe

added at this time. Use commercial grade antifreeze

designed for HVAC systems only. Do not use

automotive grade antifreeze.

Oncethesystemhasbeenlledwithcleanwater

and antifreeze (if used), precautions should

be taken to protect the system from dirty water

conditions. Dirty water will result in system wide

degradation of performance and solids may clog

valves,strainers,owregulators,etc.Additionally,

the heat exchanger may become clogged which

reduces compressor service life or causes

premature failure.

6. Set the loop water controller heat add setpoint

to 70°F (21°C) and the heat rejection setpoint to

85°F (29°C). Supply power to all motors and start

thecirculatingpumps.Afterfullowhasbeen

established through all components including the

heat rejector (regardless of season) and air vented

and loop temperatures stabilized, each of the

conditioners will be ready for check, test and start-

up, air balancing, and water balancing.

Loading...

Loading...