Controls

www.DaikinApplied.com 17 IM 1049-9

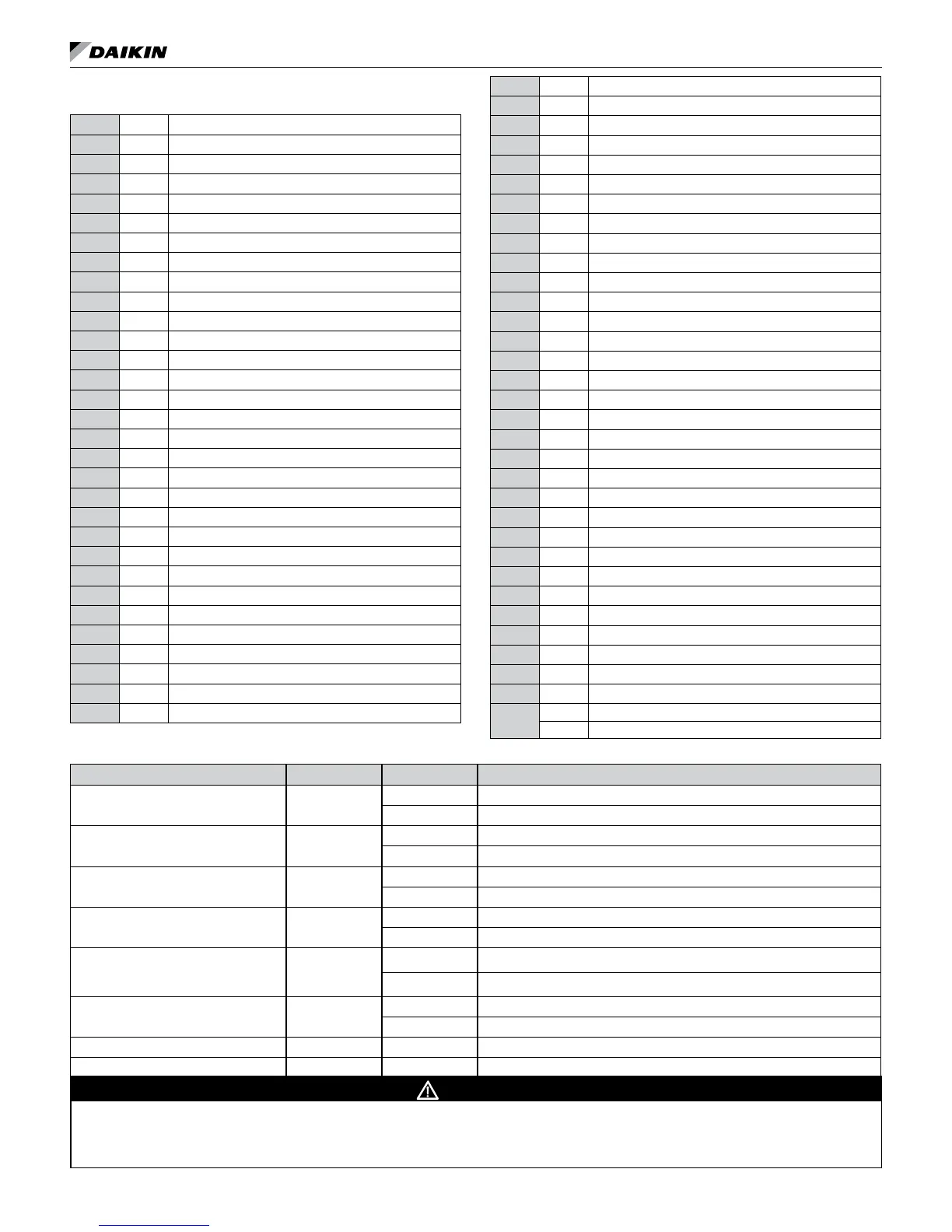

Table 5: MicroTech III unit controller terminals locations

and descriptions

H1 – 1 24 24 VAC Power Input

H1 – 2 C 24 VAC common

H2 – 1 SL1 Fan Low Speed Output – Switched L1

H2 – 2 Blank Terminal

H2 – 3 N Fan Low Speed Output – Neutral

H3 – 1 HP1-1 Comp High Pressure Switch (HP1) Input Terminal 1

H3 – 2 HP1-2 Comp High Pressure Switch (HP1) Input Terminal 2

H4 – 1 1 Discharge Air Temp Sensor – Common

H4 – 2 Discharge Air Temp Sensor – Signal

H4 – 3 Leaving Water Temp Sensor – Common

H4 – 4 Leaving Water Temp Sensor – Signal

H5 – 1 1 I/O Expansion Module Common (Gnd)

H5 – 2 I/O Expansion Module Common (Gnd)

H5 – 3 I/O Expansion Module +5 VDC

H5 – 4 I/O Expansion Module SPI CE1

H5 – 5 I/O Expansion Module SPI CLK

H5 – 6 I/O Expansion Module SPI OUT

H5 – 7 I/O Expansion Module SPI IN

H5 – 8 I/O Expansion Module +12 VDC

H5 – 9 I/O Expansion Module 24 VAC

H5 – 10 I/O Expansion Module 24 VAC

H5 – 11 No Connection

H5 – 12 No Connection

H6 – 1 1 CondensateOverowSignalInput

H6 – 2 Comp#1 Suction Temp Sensor (LT1) – Common

H6 – 3 Comp#1 Suction Temp Sensor (LT1) – Signal

H6 – 4 Comp#1 Low Pressure Switch (LP1) – Source Voltage

H6 – 5 Comp#1 Low Pressure Switch (LP1) – Signal

H6 – 6 Reversing Valve#1 – Common

H6 – 7 Reversing Valve#1 – Output

H7 – 1 1 No Connection

H7 – 2 No Connection

H7 – 3 Red LED Output

H7 – 4 Green LED Output

H7 – 5 Yellow LED Output

H7 – 6 Red-Green-Yellow LED Common

H8 – 1 1 Isolation Valve/Pump Request Relay N/O

H8 – 2 Isolation Valve/Pump Request Relay N/C

H8 – 3 24 VAC Common

H9 – 1 1 Room Temp Sensor & Tenant Override – Signal

H9 – 2 Room Temp Sensor & Tenant Override – Common

TB1 – 1 1 Room Sensor – Status LED Output

TB1 – 2 2 Room Sensor – Fan Mode & Unit Mode Switches

TB1 – 3 3 Room Sensor – Setpoint Adjust

TB1 – 4 4 Room Sensor – Room Temp Sensor & Tenant Override

TB1 – 5 5 Room Sensor – DC Signal Common

TB2 – 1 R 24 VAC

TB2 – 2 A Alarm Output

TB2 – 3 W2 Thermostat – Heat Stage #2 Input

TB2 – 4 W1 Thermostat – Heat Stage #1 Input

TB2 – 5 Y2 Thermostat – Cool Stage #2 Input

TB2 – 6 Y1 Thermostat – Cool Stage #1 Input

TB2 – 7 G Thermostat – Fan Input

TB2 – 8 O Thermostat – Tenant Override Input

TB2 – 9 C 24 VAC Common

TB3 – 1 E Emergency Shutdown Input

TB3 – 2 U Unoccupied/Occupied Input

L1 – 1 L1 - 1 Line Voltage Terminal 1

L1 – 2 L1 - 2 Line Voltage Terminal 2

L1 – 3 L1 - 3 Line Voltage Terminal 3

N1 N1 Neutral Terminal 1

N2 N2 Neutral Terminal 2

N3 N3 Neutral Terminal 3

COMP

Relay

SWL1 Switch – L1 Voltage

L1 No Connection

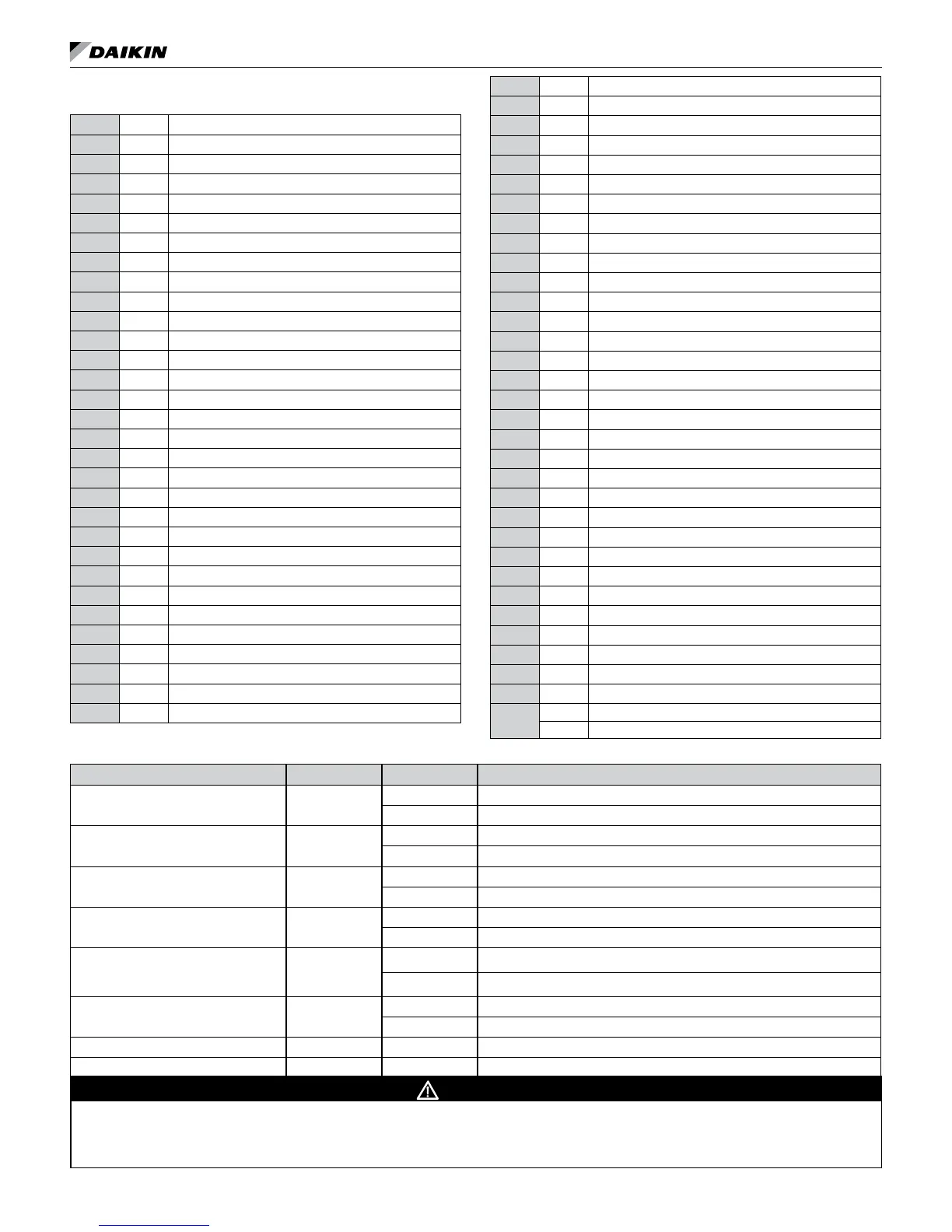

Table 6: MicroTech III Controller Configuration Jumper Settings

Baseboard Description Jumper(s) Jumper Setting Function

Normal / Test Mode JP1

Open Normal Operation

Shorted Service / Test Mode

Fan Operation JP2

Open Continuous Fan Operation (On), when not operating in the unccupied mode.

Shorted Cycling Fan Operation (Auto)

Loop Fluid

JP3

(see warning)

Open Water freeze protection (factory default setting)

Shorted Systems with anti-freeze protection

Alarm "A" Terminal Output Polarity JP4

Open Fault de-energizes alarm output to 0VAC.

Shorted Fault energizes alarm output to 24VAC.

Room Sensor Setpoint

Potentiometer Range

JP5

Open Short Range: -3 to +3 ºF (-1.67 to +1.67 ºC)

Shorted Long Range: 55 to 95 ºF (12.78 to 35 ºC)

Thermostat / Room Sensor JP6

Open Thermostat Control

Shorted Room Sensor Control

Not Used JP7 Open –

Not Used JP8 Open –

WARNING

Properantifreeze/watersolutionisrequiredtominimizethepotentialofuidfreeze-up.JumperJP3isfactorysetforwaterfreezeprotectionwiththejumperopen.Operationwithanti-freeze

protectionrequiresJP3tobeeldconguredforthejumperclosed.Ifunitisemployingafreshwatersystem(noanti-freezeprotection),itisextremelyimportantthatJP3jumpersetting

remains in the open position (factory default setting) in order to shut down the unit at the appropriate water temperature to protect your heat pump from freezing. Failure to do so can result

inunitdamageanduidleaks.”

Loading...

Loading...