FTX-N/U, FVXS-N, FDMQ-R Series EDUS091558E

117

3P500432-1

• The refrigerant is pre-charged in the outdoor unit.

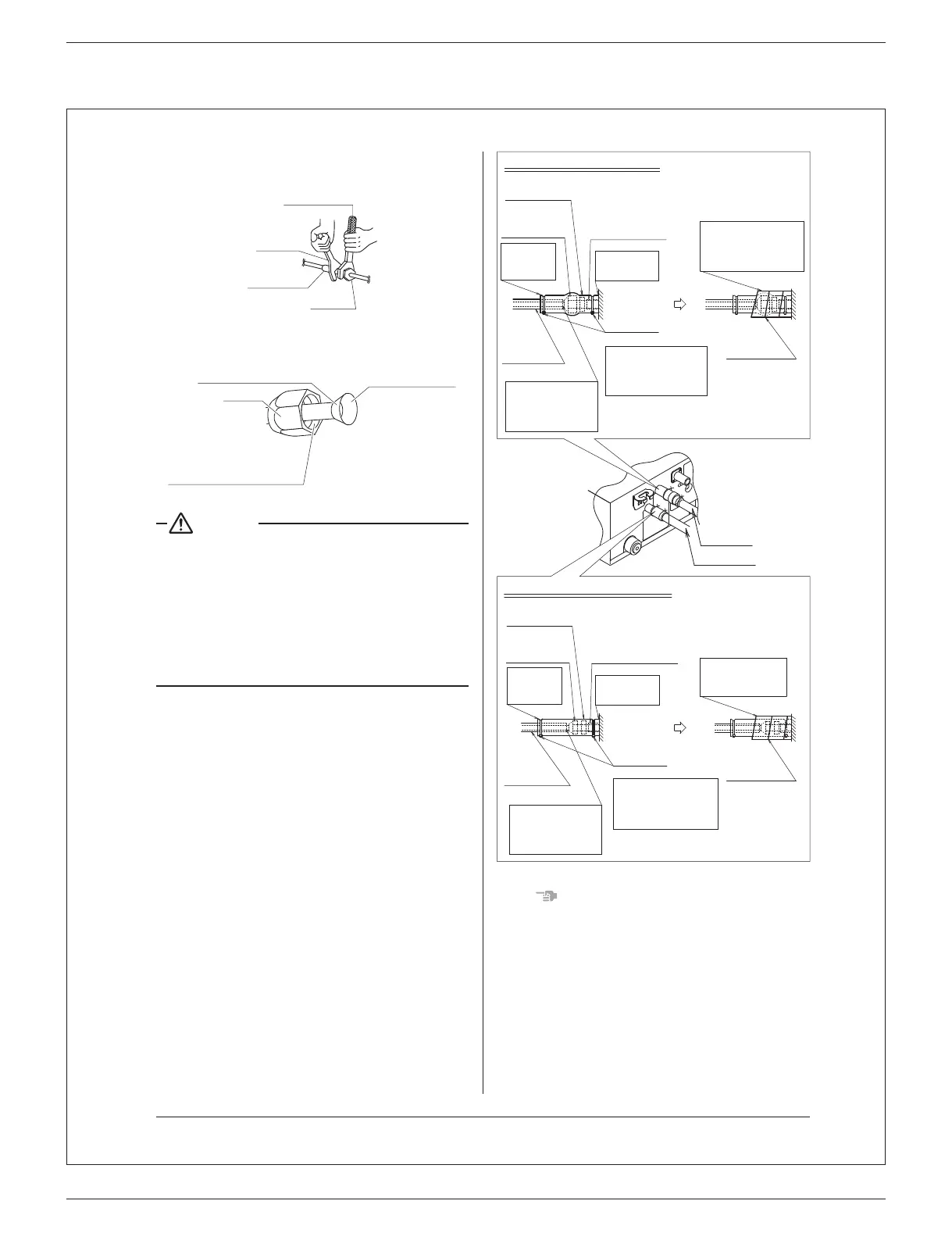

Torque wrench

Piping union

Flare nut

Spanner

Fig. 9

Do not apply refrigeration

oil to the outer surface.

Flare nut

Apply refrigeration

oil only to the inner

surface of the flare.

Do not apply refrigeration oil to

the flare nut to avoid tightening

with excessive torque.

Fig. 10

CAUTION

Donothaveoiladheretothescrewxingpartofresin

parts.

If oil adheres, it may weaken the strength of screwed part.

Donottightenarenutstootight.

If a flare nut cracks, the refrigerant may leak.

Insulationofeldpipingmustbecarriedoutuptothe

connection inside the casing.

If the piping is exposed to the atmosphere, it may cause

sweating, burn due to touching the piping, electric shock or a

re due to the wiring touching the piping.

•

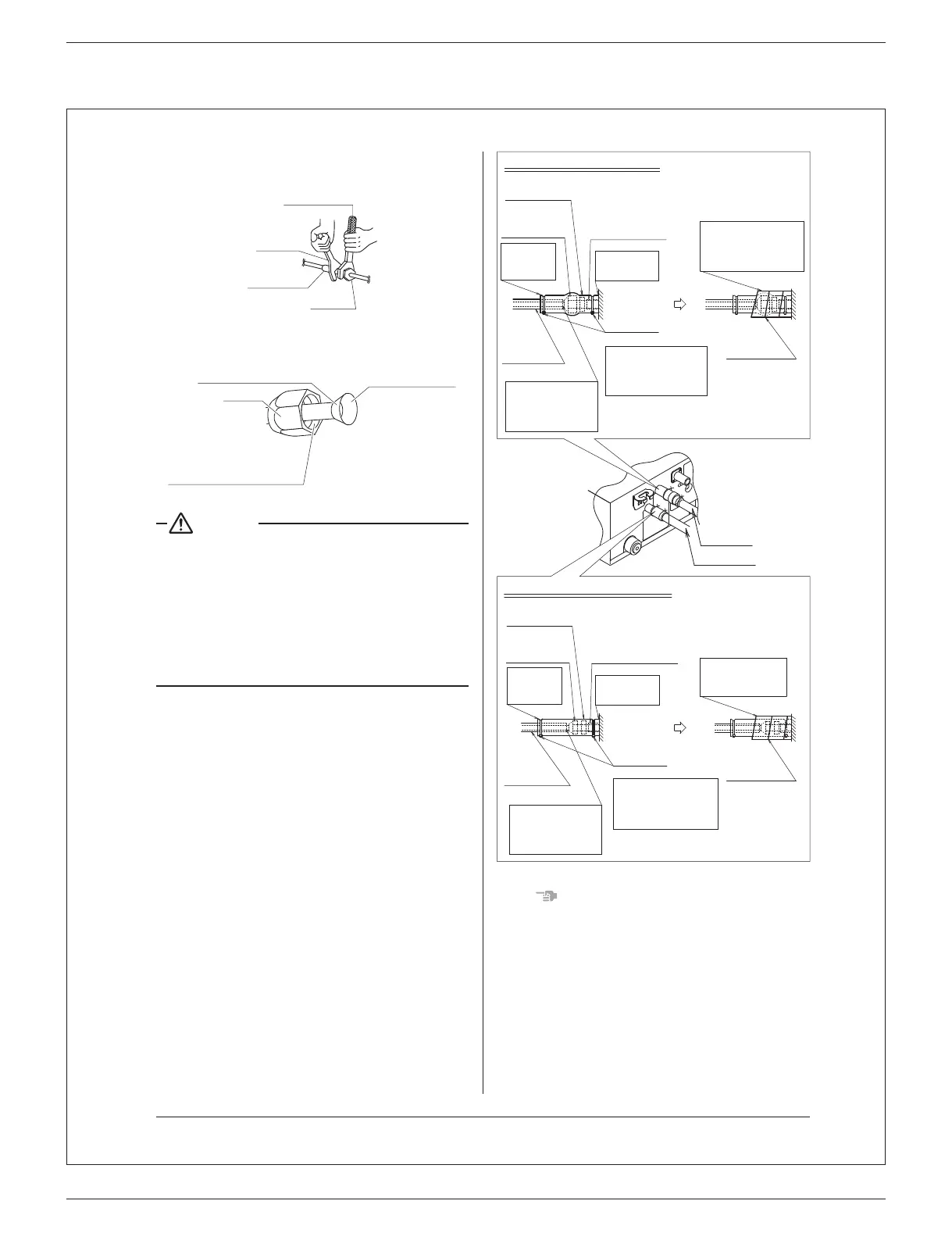

After leak test, referring to Fig. 11, insulate both the gas and

liquid piping connection with the attached tting insulation

(4) and (5) to prevent the pipings from getting exposed.

Then, tighten both the ends of insulating material with the clamp (8).

•

Wrap the sealing pad (Medium) (7) around the tting insulation

(4) and (5) (flare nut section), both the gas and liquid piping.

• Make sure to bring the seam of tting insulation (4) and (5)

to the top.

Gas piping

Liquid piping

Fitting

insulation (4)

Liquid Piping Insulation Procedure

Unit

Unit

Clamp (8)

Clamp (8)

Piping

insulating

material

(eld supply)

Gas Piping Insulation Procedure

Fitting

insulation (5)

Piping insulating

material (unit)

Bring the

seam

to the top.

Flare nut

connection

Piping

insulating

material

(eld supply)

Do not leave

clearance.

Flare nut

connection

Bring the

seam

to the top.

Do not leave

clearance.

Piping insulating

material (unit)

Wind around the

piping until top of the

flare nut connection,

beginning at the base.

Do not expose the

piping in order to

prevent the vapor

condensation.

Tighten the portion

where overlapped by

the piping insulating

material.

Tighten the portion

where overlapped by

the piping insulating

material.

Do not expose the

piping in order to

prevent the vapor

condensation.

Wind around the

piping, beginning

at the base.

Sealing pad

(Medium) (7)

Sealing pad

(Medium) (7)

Fig. 11

NOTE

1. In case of refrigerant shortage due to forgetting additional

refrigerant charge etc., it will result in malfunc tion such as

does not cool or does not heat.

Refer to the outdoor unit installation manual or technical

document for refrigerant piping.

8

01_EN_3P500432-1.indd 8 10/24/2017 18:32:33

Loading...

Loading...