6 Piping installation

Installation manual

9

CVXM-A, FVXM-A, CVXM-A9, FVXM-A9, FVXTM-A

Split system air conditioners

3P477070-2P – 2022.09

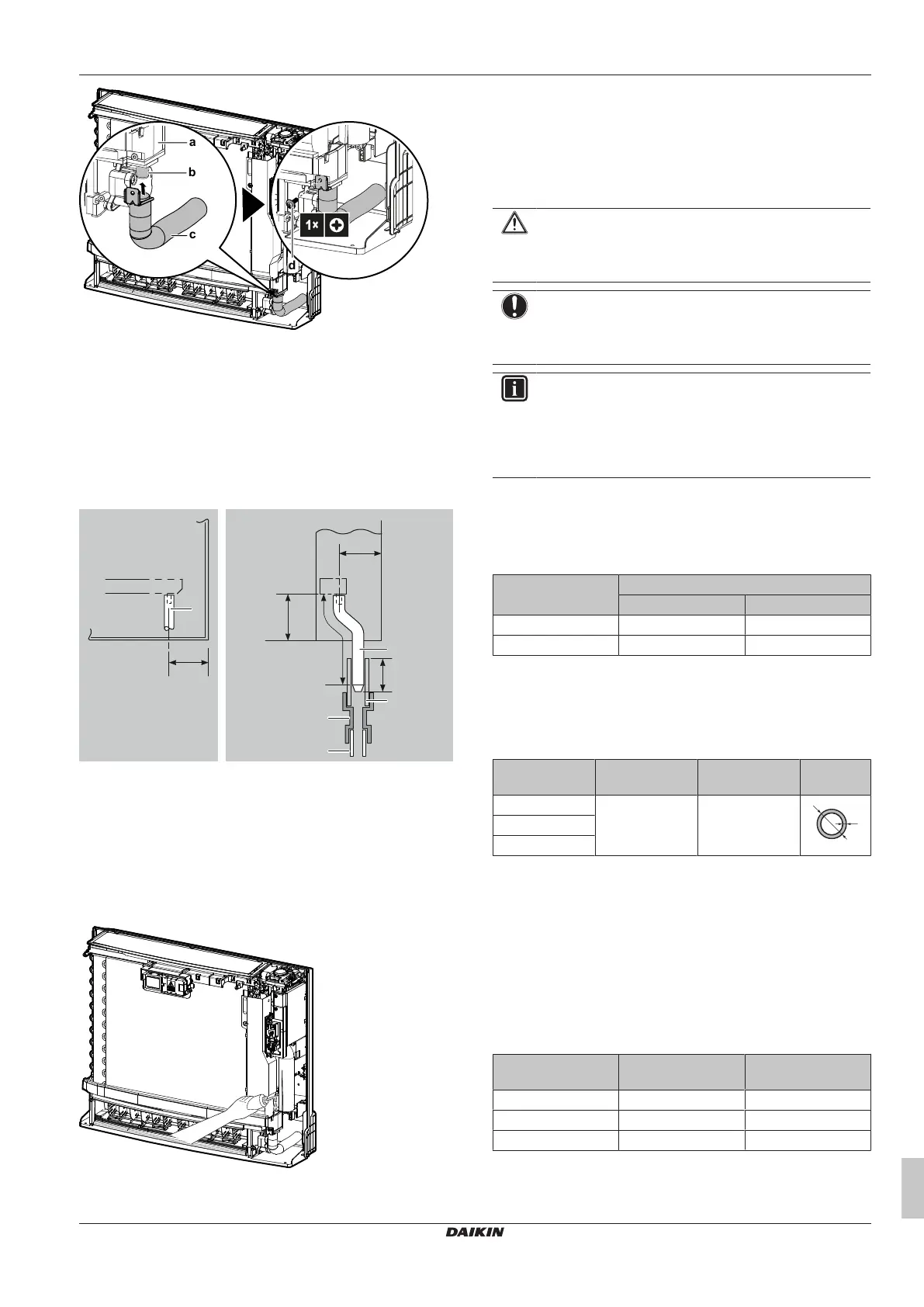

a Drain pan

b Drain socket

c Drain hose (accessory)

d Screw (accessory)

2 Check for water leaks (see "5.3.3 To check for water

leaks"[49]).

3 Insulate the indoor drain socket and drain hose with ≥10 mm

insulation material to prevent condensation.

4 Connect the drain piping to the drain hose. Insert the drain hose

≥50mm, so it will not be pulled out of the drain pipe.

a Drain hose (accessory)

b Vinyl chloride drain pipe (VP-30) (field supply)

c Reducer (field supply)

d Vinyl chloride drain pipe (VP-20) (field supply)

5.3.3 To check for water leaks

1 Remove the air filters.

2 Gradually pour approximately 1l of water in the drain pan, and

check for water leaks.

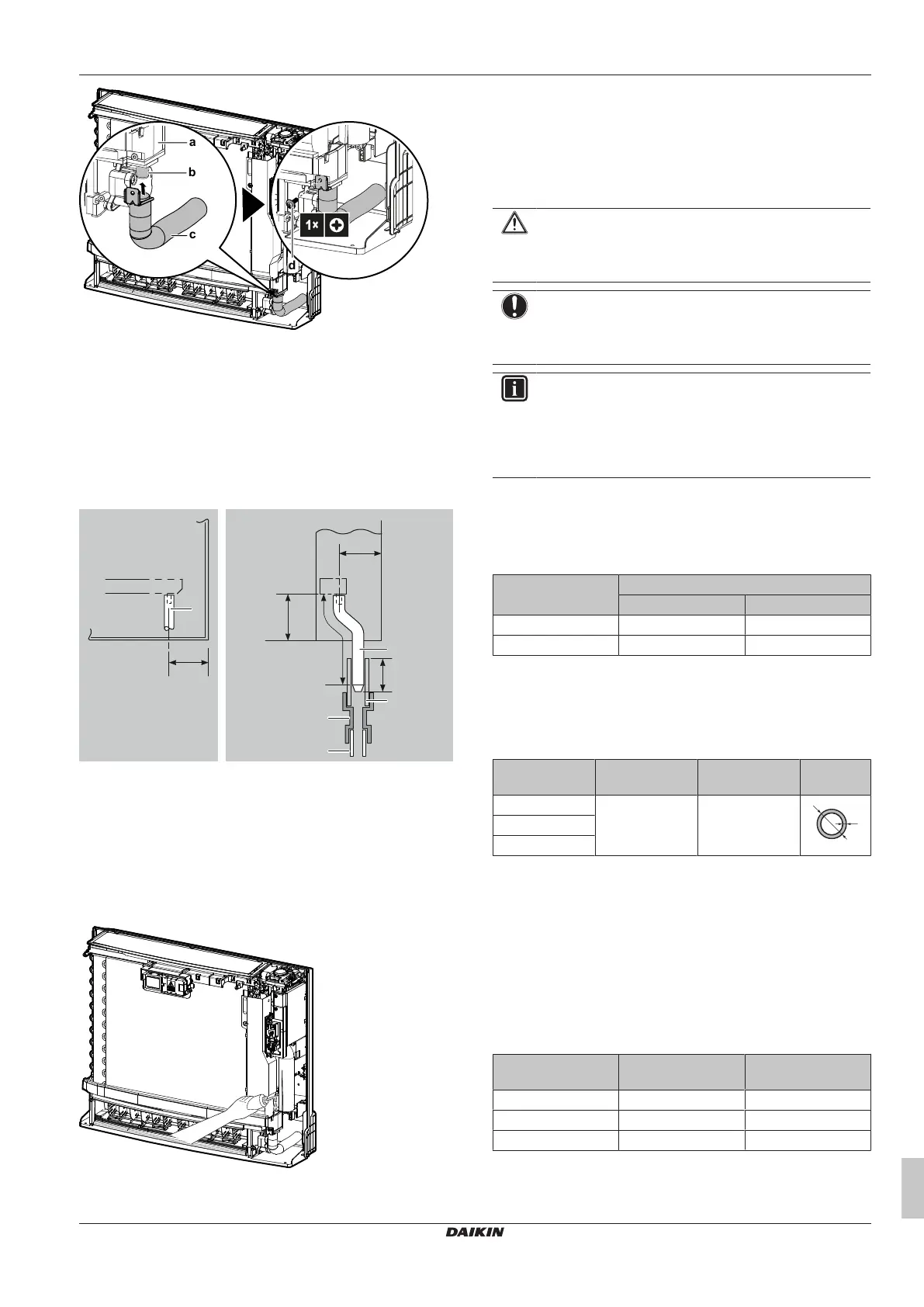

6 Piping installation

6.1 Preparing refrigerant piping

6.1.1 Refrigerant piping requirements

CAUTION

Piping and joints of a split system shall be made with

permanent joints when inside an occupied space except

joints directly connecting the piping to the indoor units.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant piping.

INFORMATION

Additional refrigerant charge is NOT allowed in case of

combination of the outdoor unit 3MXM40 or 3MXM52 with

the indoor units CVXM-A and/or FVXM-A. The total piping

length MUST be ≤30m. For CVXM-A9 and FVXM-A9 refer

to "To determine the minimum floor area"[45].

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30mg/10m.

Refrigerant piping diameter

Use the same diameters as the connections on the outdoor units:

Class Pipe outer diameter (mm)

Liquid piping Gas piping

20~35 Ø6.4 Ø9.5

50 Ø6.4 Ø12.7

Refrigerant piping material

▪ Piping material: phosphoric acid deoxidised seamless copper

▪ Flare connections: Only use annealed material.

▪ Piping temper grade and thickness:

Outer diameter

(Ø)

Temper grade Thickness (t)

(a)

6.4mm (1/4") Annealed (O) ≥0.8mm

9.5mm (3/8")

12.7mm (1/2")

(a)

Depending on the applicable legislation and the maximum

working pressure of the unit (see "PS High" on the unit name

plate), larger piping thickness might be required.

6.1.2 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Ø

p

)

Insulation inner

diameter (Ø

i

)

Insulation thickness

(t)

6.4mm (1/4") 8~10mm ≥10mm

9.5mm (3/8") 12~15mm ≥13mm

12.7mm (1/2") 14~16mm ≥13mm

Loading...

Loading...