10 IM 962-2

Installation

Installation

Order Parts

When reporting shortages or damaged parts, or when

ordering repair parts, give the complete unit model and serial

numbers which are stamped on the unit rating plate.

Standard Items

The condensing unit consists of a completely assembled

package which includes a compressor pack, condenser coils,

fans, fan motors, outdoor control box, factory wiring, factory

tubing and ttings.

Crankcase Heaters

These units are equipped with a crankcase heater that is

factory wired to operate whenever the main power supply

to the unit is “ON” and compressors are “OFF.” Before

starting the equipment after prolonged shutdown or at the

time of initial spring startup, be sure that the circuits to the

condensing units are closed for at least 24 hours.

Corrosive Environment

The metal parts of this unit may be subject to rust or

deterioration if exposed to a corrosive environment. This

oxidation could shorten the equipment’s useful life. Corrosive

elements include salt spray, fog or mist in seacoast areas,

sulphur or chlorine from lawn watering systems, and various

chemical contaminants from industries such as paper mills

and petroleum reneries.

If the unit is to be installed in an area where contaminants are

likely to be a problem, special attention should be given to the

equipment location and exposure.

• Avoid having lawn sprinkler heads spray directly on the

unit cabinet

• In coastal areas, locate the unit on the side of the

building away from the waterfront.

• Shielding provided by a protection, based on clearances

DANGER

Disconnect all power to unit before starting maintenance.

Failure to do so can cause electrical shock resulting in severe

personal injury or death.

Regular maintenance will reduce the buildup of contaminants

and help to protect the unit’s nish.

• Frequent washing of the cabinet, fan blade and coil

with fresh water will remove most of the salt or other

contaminants that build up on the unit.

• Regular cleaning and waxing of the cabinet with a good

automobile polish will provide some protection.

• A good liquid cleaner may be used several times a year

to remove matter that will not wash off with water.

Several different types of protective coatings are offered in

some areas. These coatings may provide some benet, but the

effectiveness of such coating materials cannot be veried by

the equipment manufacturer.

Installation General

The condensing unit should be installed outdoors. It should be

located as near as possible to the evaporator section to keep

connecting refrigerant tubing lengths to a minimum. The unit

must be installed to allow a free air ow to the condenser coils

If several units are installed adjacent to each other, take care

to avoid recirculation of air from one condenser to another.

In all installations, adequate space must be provided for

installation and servicing.

The unit must not be connected to any duct work. Do not

locate unit under a roof drip; if necessary, install gutters,

etc., to prevent water runoff onto the unit. To prevent air

recirculation, it is recommended that the unit not be installed

under an overhang. However, if this is necessary, allow a

minimum of 60" above the unit for air discharge

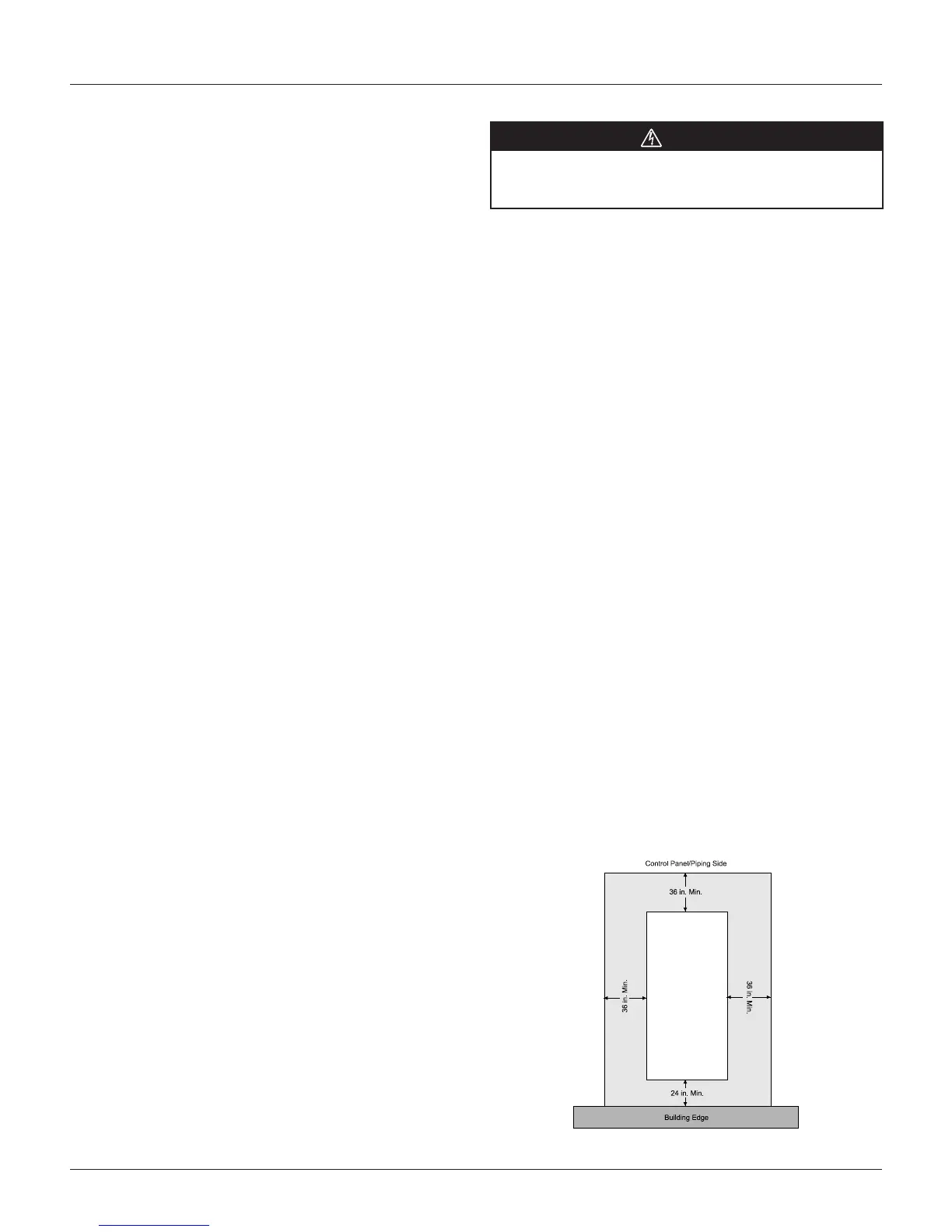

Figure 8: Clearances RCS 06F – 20F Service Clearances

Loading...

Loading...