16 IM 962-2

Installation

Refrigerant Charge

Leak Testing

Pressurize line set and coil through service ttings with dry

nitrogen to 150 psig maximum. Leak test all joints using

liquid detergent. If a leak is found, recover pressure and

repair.

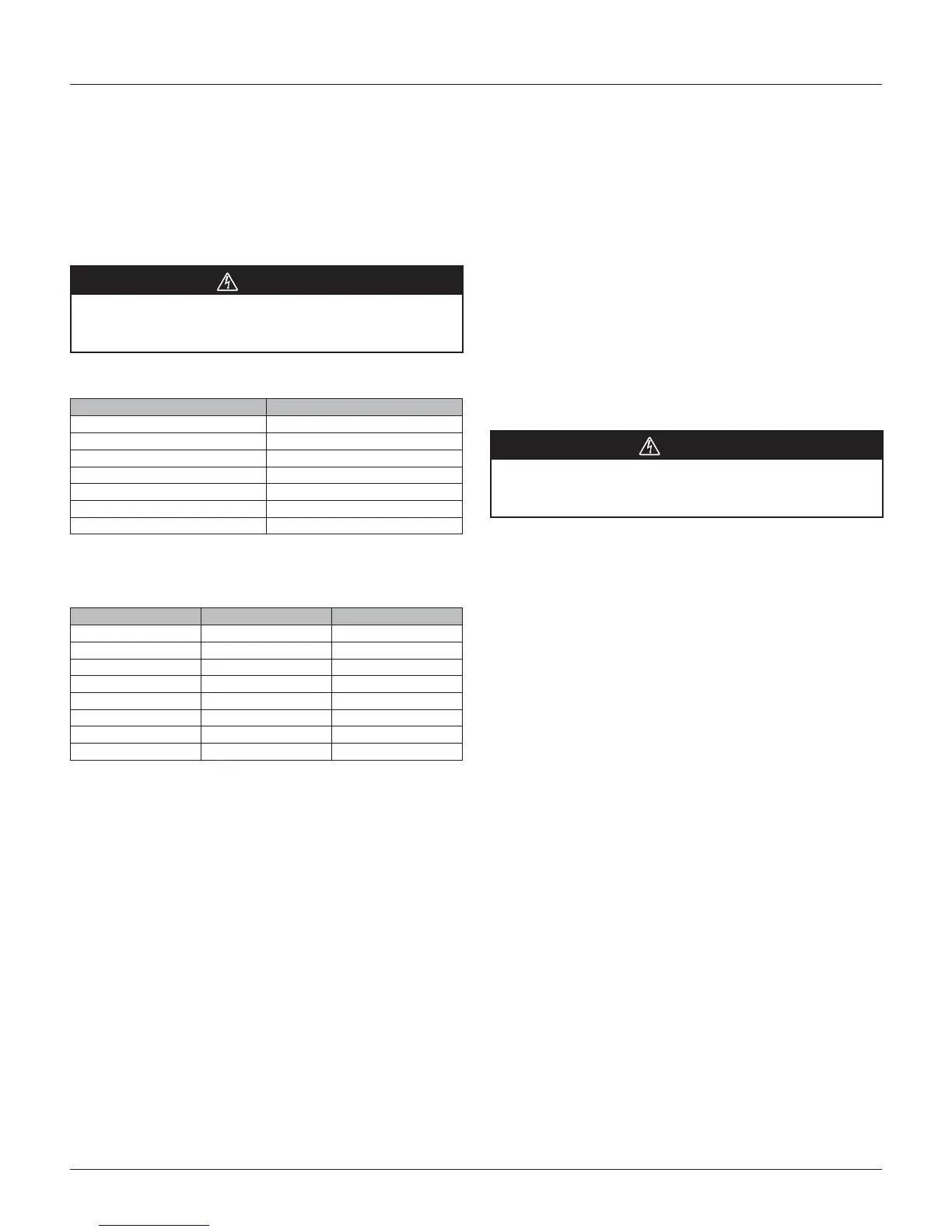

WARNING

Do not use oxygen to purge lines or pressure system for leak

test. Oxygen reacts violently with oil, which can cause an

explosion resulting in severe personal injury or death.

Table 12: Basic System Charge*

Unit Charge oz [g]

06F 178 [5046]

07F 242 [6861]

10F 339 [9661]

11F 300 [8505]

12F 378 [10,716]

15F 506 [14,345]

20F 655 [18,569]

Note: *System with 0 Feet of Tubing

Table 13: Required Ounces of R410A Charge per Foot of

Tubing

Tube Size O.D., in [mm] Liquid Tube, oz [g] Vapor, oz [g]

1/2 [12.7] 1.06 [30.0] 0.04 [1.13]

5/8 [15.88] 1.65 [46.7] 0.07 [1.98]

3/4 [19.05] 2.46 [69.7] 0.10 [2.83]

7/8 [22.23] 3.28 [92.9] 0.13 [3.68]

1-1/8 [28.58] — 0.22 [6.23]

1-3/8 [34.93] — 0.34 [9.63]

1-5/8 [41.28] — 0.48 [13.60]

2-1/8 [53.98] — 0.84 [23.81]

Note: Quantities based on 110°F liquid and 45°F vapor

Tools Required for Installing and Servicing

R410A Models

Manifold Sets:

• Up to 800 PSIG High side

• Up to 250 PSIG Low Side

• 550 PSIG Low Side Retard

Manifold Hoses:

• Service Pressure Rating of 800 PSIG

Recovery Cylinders:

• 400 PSIG Pressure Rating

• Dept. of Transportation 4BA400 or BW400

CAUTION

R410A systems operate at higher pressures than R22

systems. Do not use R22 service equipment or components

on R410A equipment

Specication of R410A

Application: R410A is not a drop-in replacement for R22;

equipment designs must accommodate its higher pressures. It

cannot be retrotted into R22 condensing units.

Physical Properties: R410A has an atmospheric boiling point

of 62.9°F and its saturation pressure at 77°F is 224.5 psig.

Composition: R410A is an azeotropic mixture of 50%

by weight diuoromethane (HFC32) and 50% by weight

pentauoroethane (HFC125).

Pressure: The pressure of R410A is approximately 60% (1.6

times) greater than R22. Recovery and recycle equipment,

pumps, hoses and the like need to have design pressure

ratings appropriate for R410A. Manifold sets need to range

up to 800 psig high-side and 250 psig low-side with a 550

psig low-side retard. Hoses need to have a service pressure

rating of 800 psig. Recovery cylinders need to have a 400 psig

service pressure rating. DOT 4BA400 or BW400.

Combustibility: At pressures above 1 atmosphere, mixture

of R410A and air can become combustible. R410A and air

should never be mixed in tanks or supply lines, or be allowed

to accumulate in storage tanks. Leak checking should never

be done with a mixture of R410A and air. Leak checking can

be performed safely with nitrogen or a mixture of FR410A

and nitrogen.

Loading...

Loading...