4 IM 962-2

Introduction

Introduction

Standard Unit Features

Cabinet — Galvanized steel with a durable powder paint

nish. Stamped louvered panels offer 100% protection for the

condenser coil.

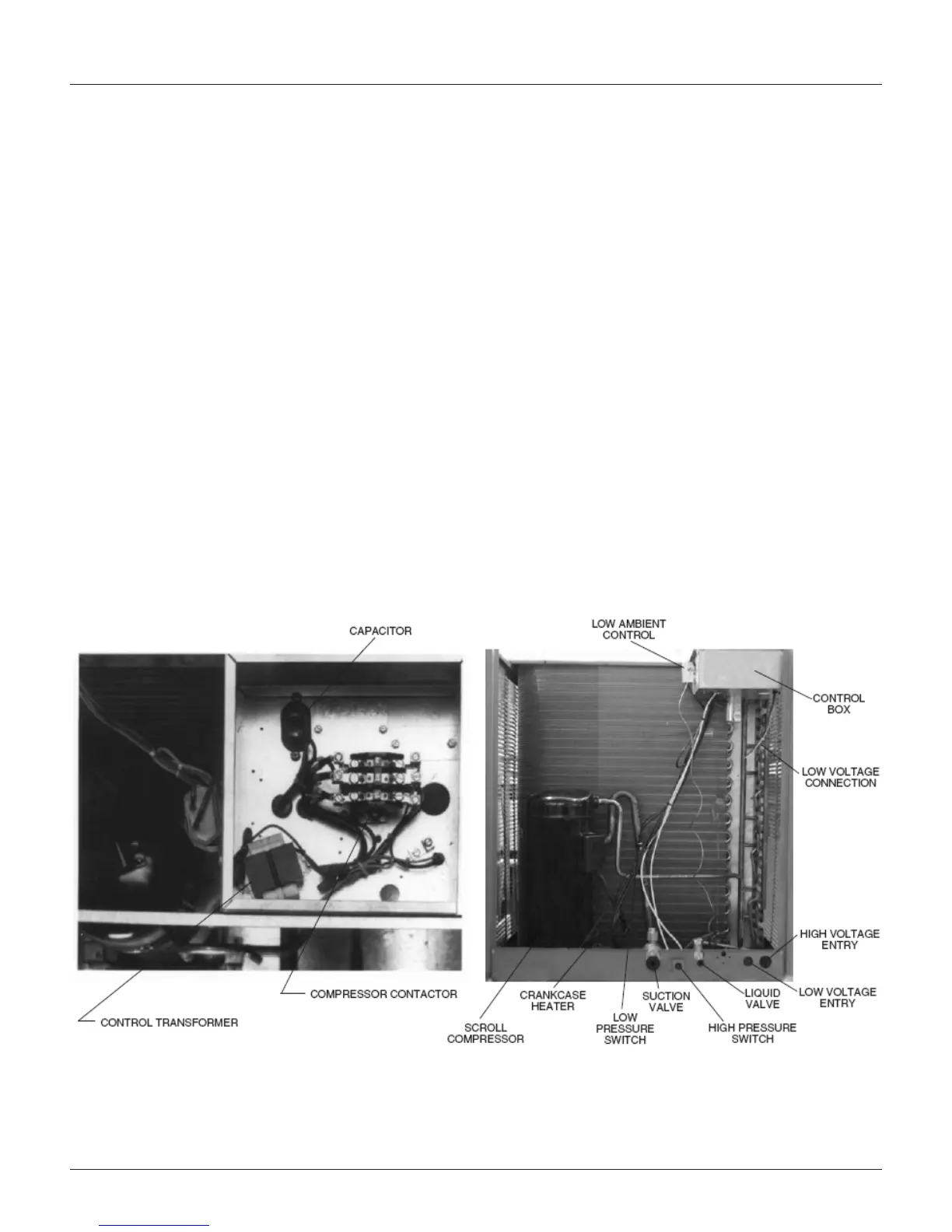

Compressor — Hermetically sealed scroll compressors.

Compressors are mounted on rubber-in-shear pads to reduce

vibration and noise.

Condenser Coil — Constructed with copper tubes and

aluminum ns mechanically bonded to the tubes for

maximum heat transfer capabilities. All coil assemblies are

leak tested at 450 psig internal pressure.

Refrigerant Connections — Field piping connections are made

through a xed panel. This allows complete access or removal of

access panels after piping connections have been made.

Crankcase Heater — Standard, all models.

Low Ambient Control — A pressure sensitive fan cycling

control to allow unit operation to 0°F is standard.

Service Valves — Standard on liquid lines and vapor lines.

Service Access — The control box, as well as the

compressor and other refrigerant controls, is accessible

through access panels. It may be opened without affecting

the normal operation of the unit. Condenser fan motors are

accessible by removing wire grilles.

Filter Drier — Field supplied.

Sight Glass — Optional, eld supplied.

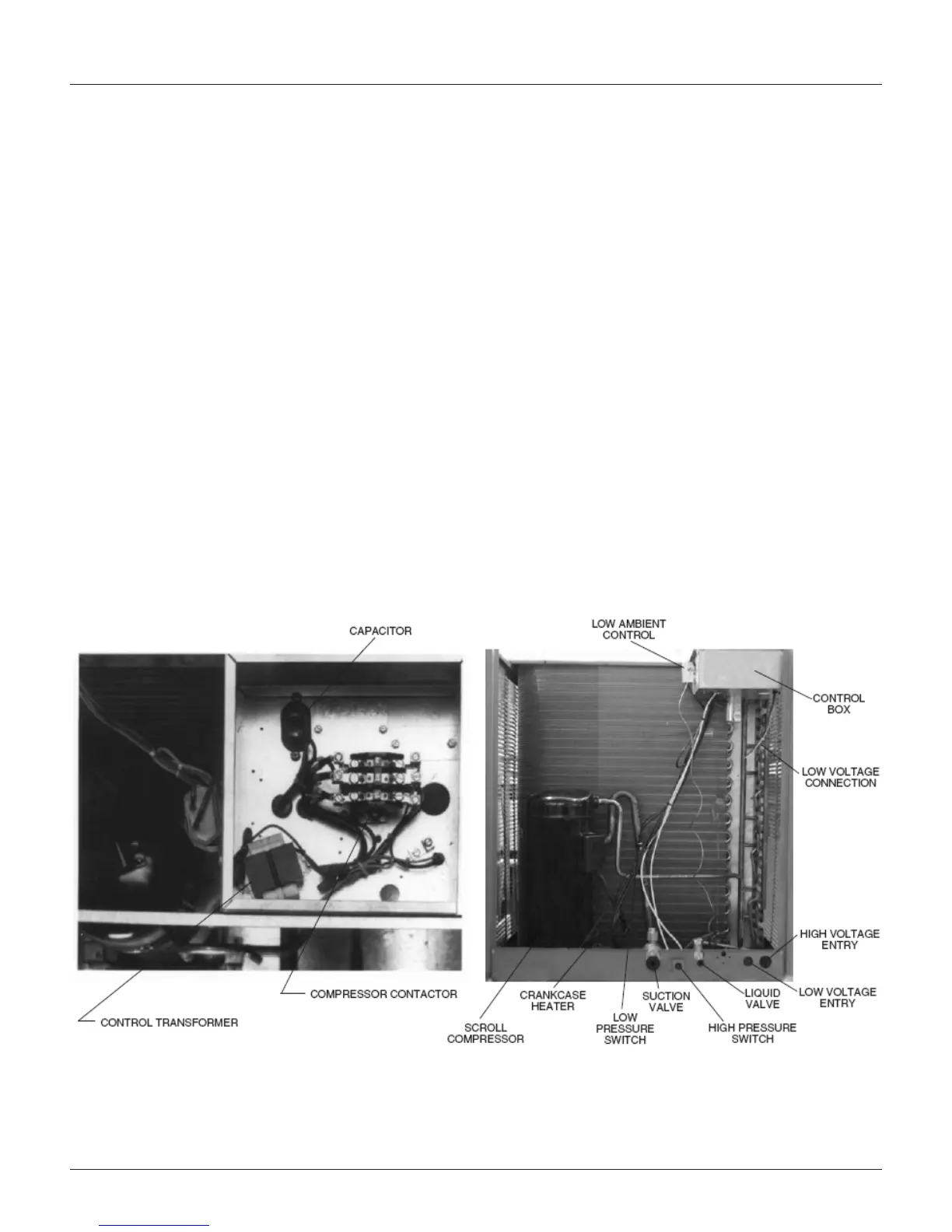

Transformer — Step down type, line to 24 volts.

Contactor — The contactor is an electrical switch which

operates the compressor and condenser fans.

High Pressure Control — Opens the contactor circuit on

high refrigerant pressure; manual reset.

Low Pressure Control — Stops compressor operation in the

event of loss of refrigerant.

Condenser Fan Motor (Direct Drive) — Ball bearing 1075

RPM motors are mounted to minimize vibration and noise

problems.These are permanent split capacitor types and

require the same capacitance for both run and start.

Testing — All units are run tested at the factory prior to

shipment. Units are shipped with a holding pressure of nitrogen.

Figure 1: RCS 06F & 07F Ton Features

Loading...

Loading...