IM 893-10 • ROOFPAK SINGLEZONE UNITS 130 www.DaikinApplied.com

MaInTenanCe

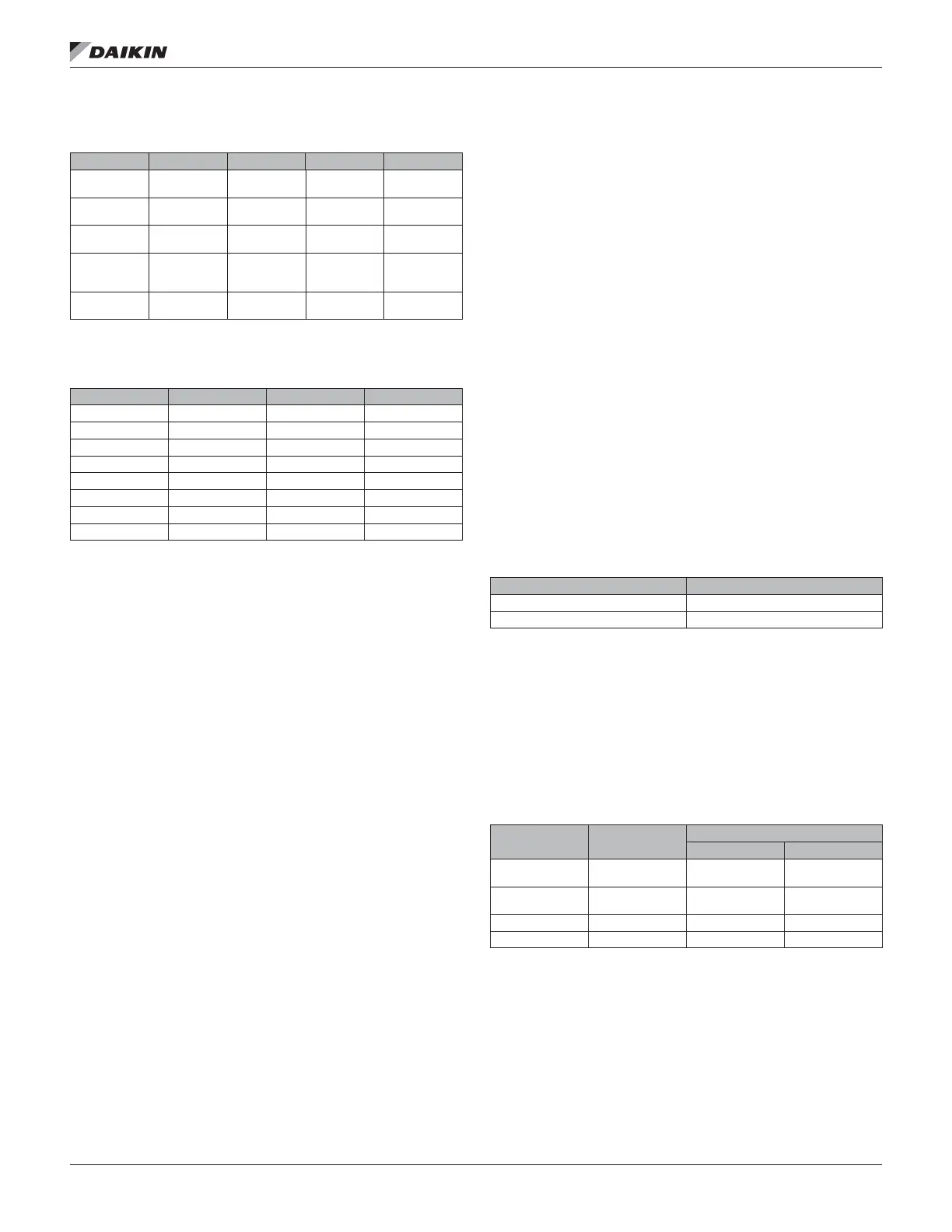

Table 25: Recommended Lubricants for Fan Shaft Ball

Bearings

Name Temperature Base Thickener NLGI grade

Texaco,

Premium RB

30° to 350°F

(34° to 177°C)

Paranic

mineral oil

Lithium 2

Mobile, AW2

40° to 437°F

(40° to 175°C)

Mineral oil Lithium 2

Mobile, SHC

100

68° to 356°F

(50° to 180°C)

Synthetic Lithium 2

Chevron,

Altiplex

Synthetic

60° to 450°F

(51° to 232°C)

Synthetic Lithium 2

Exxon, ronex

MP

40° to 300°F

(40° to 149°C)

Mineral oil Lithium 2

Note: Temperature ranges over 225°F are shown for lubricants only. High temperature ap-

plications are not suitable for standard air handler components.

Table 26: Recommended Fan Relubrication Grease Charge

Shaft Size (in) Oz. Shaft Size Grams

1/2 to 3/4 0.03 20 mm 0.85

7/8 to 1-3/16 0.10 25-30 mm 2.84

1-1/4 to 1-1/2 0.15 35-40 mm 4.25

1-11/16 to 1-15/16 0.20 45-50 mm 5.67

2 to 2-7/16 0.30 55-60 mm 8.51

2-1/2 to 2-15/16 0.50 65-70 mm 15.59

3 to 3-7/16 0.85 75-80 mm 24.10

3-1/2 to 4 1.50 85-105 mm 42.53

Bearing Replacement

The following instructions must be read in entirety before

attempting installation or removal. The procedures indicated

should be carefully followed. Failure to do so can result in

improper installation which could cause bearing performance

problems as well as serious personal injury.

Bearings in Bolt-On Housings (Units)

1. 1 Check area - Clean and organize bearing installation

area and keep well lit. Be sure mounting surfaces are

clean and at.

2. 2 Check shaft - Shaft should be within tolerance range

shown in Table 27, clean, and free of nicks and burrs.

Mount bearing on unused section of shafting or repair/

replace shafting as required.

3. 3 Install unit - Slide unit onto shaft. If it is difcult to

mount bearing on shaft, use a piece of emery cloth to

reduce any high spots on shaft. Do not hammer on any

component of the bearing.

4. 4 Fasten unit in place - Install housing mounting bolts,

check and align bearing and tighten mounting bolts to

recommended fastener torques. Exercising extreme

caution and safety, rotate shaft slowly to center bearing.

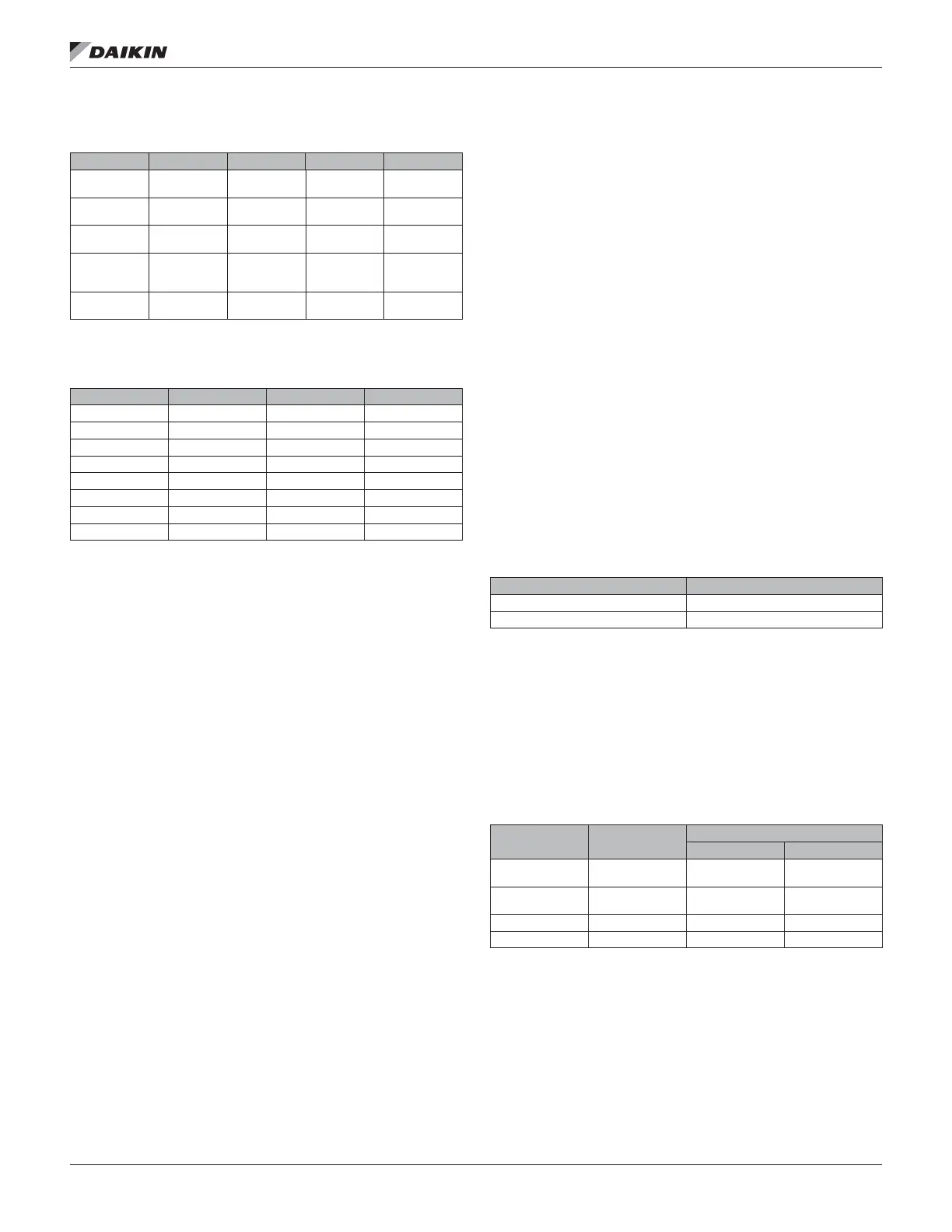

Table 27: Shaft Size Tolerances

Shaft Size (in) Tolerance

1-11/16 to 2-7/16 +0 to -0.0015

2-7/16 and up +0 to -0.002

BOA Concentric Inserts

1. Be sure that BOA Concentric collar is tted square and

snug against the shoulder on the inner ring.

2. Torque BOA Concentric collar cap screw to torque

recommended in Table 28.

Table 28: Recommended Torque Values for Concentric

Locking Bearing/Shaft Size

Fan Size (in) Bore Size (in)

Torx Screw

Size In lbs.

27 (AF)/40 & 49

(SWSI)

2-3/16 T-30 180

30 & 33 (AF)/44

(SWSI)

2-7/16 T-45 400

36 (AF) 2-11/16 T-45 400

40 (AF) 2-15/16 T-45 400

Note: AF = DWDI AF, SWSI = AF Plenum Fan

Monitor Installed Bearing

After bearing has been run for several minutes, and

again after several hours, check bearing for excessive

noise or vibration. Shutdown machine and check housing

temperature: typical applications operate at 100°F - 105°F

(38°C - 66°C). Tighten all locking devices after 500 hours or

3 months, whichever comes first.

Loading...

Loading...