Do you have a question about the Danfoss BOCK F and is the answer not in the manual?

Explains the meaning of safety symbols like DANGER, WARNING, CAUTION, ATTENTION, INFO.

Specifies the necessary qualifications for personnel working on compressors to prevent accidents.

Provides general safety warnings for handling pressurised refrigerating compressors and temperature risks.

Highlights safety aspects specific to NH3 refrigerant, including toxicity and explosiveness.

Defines the intended purpose of the compressor and prohibits other uses, especially in explosive environments.

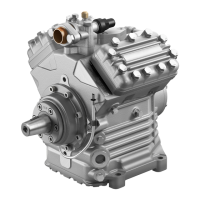

Overview of open-type compressors for external drive, with oil pump lubrication.

Details the information provided on the compressor's name plate, including type, speed, and pressure ratings.

Explains the meaning of the characters and numbers used in the compressor's type code designation.

Lists the refrigerants that can be used with the F series compressors, including HFKW, HFCKW, and NH3.

Specifies the factory-filled oil types for different refrigerants (R134a, R22) and recommends refilling types.

Details the specific oil type (Fuchs Reniso KC 68) used for NH3 compressors.

Outlines the permissible operating limits for compressors, including temperature, switching frequency, and minimum run time.

Provides guidelines for proper storage conditions, handling, and transport of compressors.

Details requirements for compressor installation, including clearance, ventilation, and mounting on a base frame.

Specifies the allowed angles and durations for compressor inclination to prevent lubrication damage.

Explains pipe connection types, diameters, and the need to match pipe cross-section to compressor capacity.

Provides requirements for pipe material, cleanliness, laying, vibration compensation, and pressure loss.

Gives guidance on the proper layout of suction and discharge lines for smooth system operation.

Describes the correct procedure for opening and closing compressor shut-off valves.

Explains how to operate the lockable service connections for safe and functional use.

Details methods for driving compressors via V-belts or shaft couplings, emphasizing alignment and safeguards.

Explains the function of oil sump heaters to prevent refrigerant diffusion into oil during standstill.

Mandates pressure and temperature controls and advises checking for transport damage before start-up.

States that the compressor is factory tested and advises system testing without the compressor.

Emphasizes using only nitrogen for pressurization and observing maximum overpressure limits during leak testing.

Details the procedure for evacuating the system and compressor to remove air and moisture.

Provides instructions for charging refrigerant, including safety precautions and avoiding overfilling.

Explains normal oil leakage from shaft seals and maintenance for ensuring fault-free operation.

Recommends changing the shaft seal only if it is losing refrigerant and refers to spare part kits.

Guides on ensuring shut-off valves are open, checking safety devices, and monitoring oil level during start-up.

Warns about slugging damage and provides measures to prevent it, like proper system design and superheat.

Outlines safety precautions before performing maintenance, including switching off and relieving pressure.

Recommends regular service checks, including oil changes and annual inspections of key components.

Informs where to find available spare parts and accessories, recommending genuine Bock parts.

Lists recommended oil grades for different refrigerants and advises using Bock-approved oils.

Provides instructions for safely draining refrigerant and disposing of oil during compressor decommissioning.

Details specific views (X, Y) of compressor connections, including oil sight glass and parallel operation facilities.

Illustrates specific views (X, Y) for F-NH3 compressors, showing oil sight glass and parallel operation connections.

| Type | Semi-hermetic |

|---|---|

| Refrigerant | R22, R404A, R507, R134a |

| Number of Cylinders | 2 to 8 |

| Application | Refrigeration and air conditioning |

| Capacity Control | Mechanical capacity control |

Loading...

Loading...