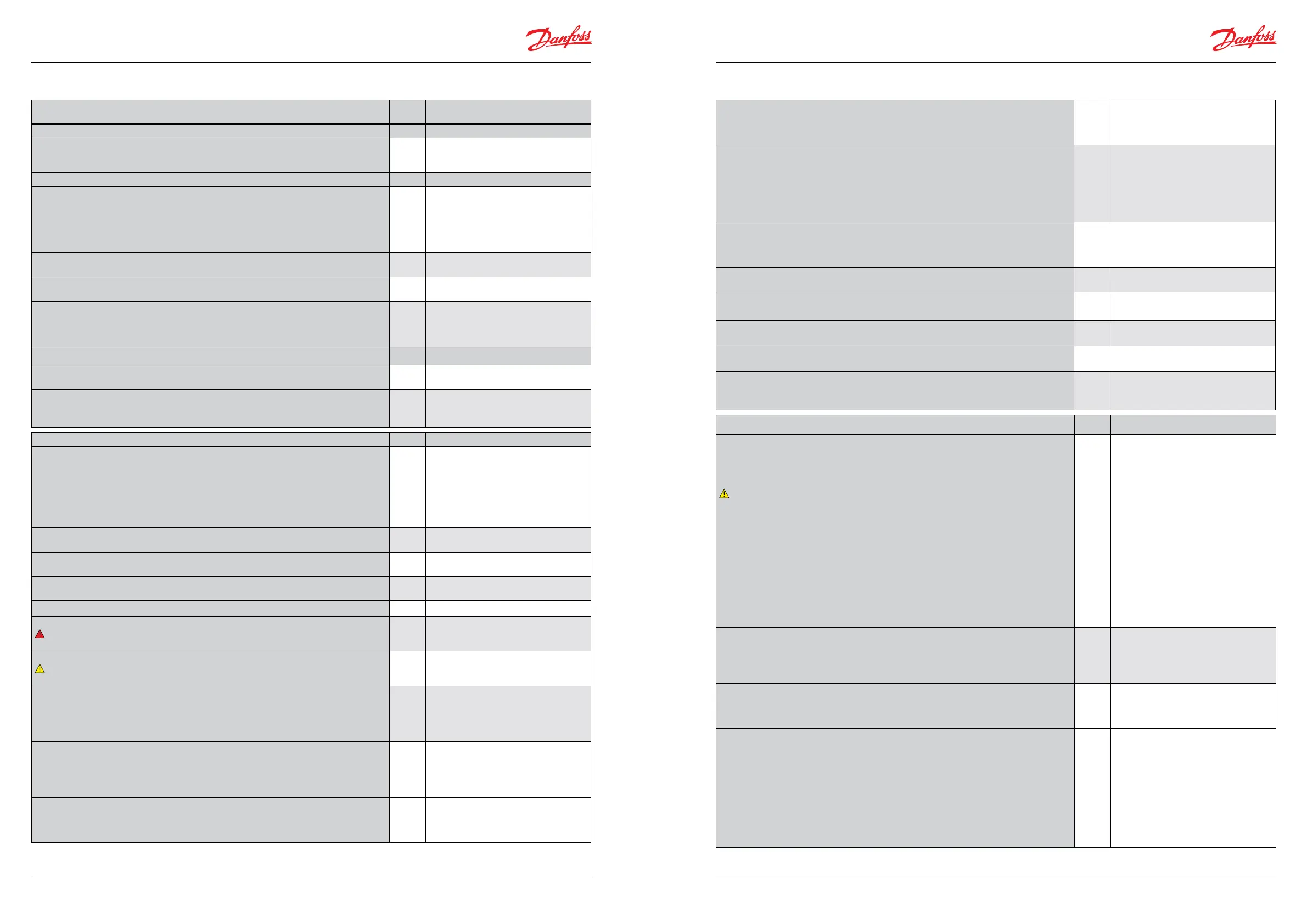

Survey of functions

Function Para-

meter

Parameter by operation via

data communication

Normal display

The superheat is normally shown.

The opening degree is displayed during manual operation or if the valve is under

analogue control.

SH/OD%

Reference Miscellaneous

Unit

Here you select whether the controller is to indicate the temperature values in °C or in

°F and pressure values in bar or psig.

If indication in °F is selected, other temperature settings will also switch to Fahrenheit,

either as absolute values or as delta.

The combination of temperature unit and pressure unit is depicted to the right.

r05

Units (Menu = Misc.)

0: °C + bar

1: °F + psig

Correction of signal from S2

(Compensation possibility through long sensor cable).

r09 Adjust S2

Correction of signal from S4

(Compensation possibility through long sensor cable).

r10 Adjust S4

Start/stop of refrigeration

With this setting, refrigeration can be started and stopped. Start/stop of refrigeration

can also be accomplished with the external switch function. See also appendix 1.

r12 Main Switch

Alarm

Alarm setting

If there is an alarm, the LEDs on the front of the external display will ash if it is con-

nected. The alarm relay in the controller is closed.

Battery alarm

Here it is dened whether the controller is to monitor the voltage from the battery

backup. If there is low voltage, or no voltage, an alarm will be given

A34 Batt. alarm

Control parameters Injection control

Valve denition

0 = ETS 12½, ETS 25, KVS 15

1 = ETS 50, CCM 10, CCM 20, CCM 30

2 = ETS 100, CCM 40

3 = ETS 250, KVS 42

4 = ETS 400

5 = user-dened

6 = Saginomiya UKV/SKV/VKV/PKV;

7 = ETS 6

8 = CCMT 2, CCMT 4, CCMT 8

n03 Valve type

On using external display EKA 164A, please check page 9 section ETS valve

P: Amplication factor Kp

If the Kp value is reduced the regulation becomes slower.

n04 Kp factor

I: Integration time Tn

If the Tn value is increased the regulation becomes slower.

n05 Tn sec.

D: Dierentiation time Td

The D-setting can be cancelled by setting the value to min. (0).

n06 Td sec.

Max. value for the superheat reference

n09 Max SH

Min. value for the superheat reference

Warning:

Due to the risk of liquid ow, the setting should not be lower than approx. 2-4 K.

n10 Min SH

MOP

Note:

If no MOP function is required, select pos. O. (A value of 200 corresponds to O)

n11 MOP (bar)

Startup time for safety signal

If the controller does not obtain a reliable signal within this period of time the con-

troller will try to establish a stable signal in other ways. (A value that is too high may

result in a ooded evaporator).

The value should only be changed by specially-trained sta .

n15 StartUp time

Signal safety during startup

The control function uses the value as a start value for the valve’s opening degree at

each thermostat cut-in. By adaptive control the controller continuously calculates a

new value.

The value should only be changed by specially-trained sta.

n17 Start OD%

Stability factor for regulation of superheat

With a higher value, the control function will allow a greater uctuation of the super-

heat before the reference is changed. The value should only be changed by specially-

trained sta.

n18 Stability

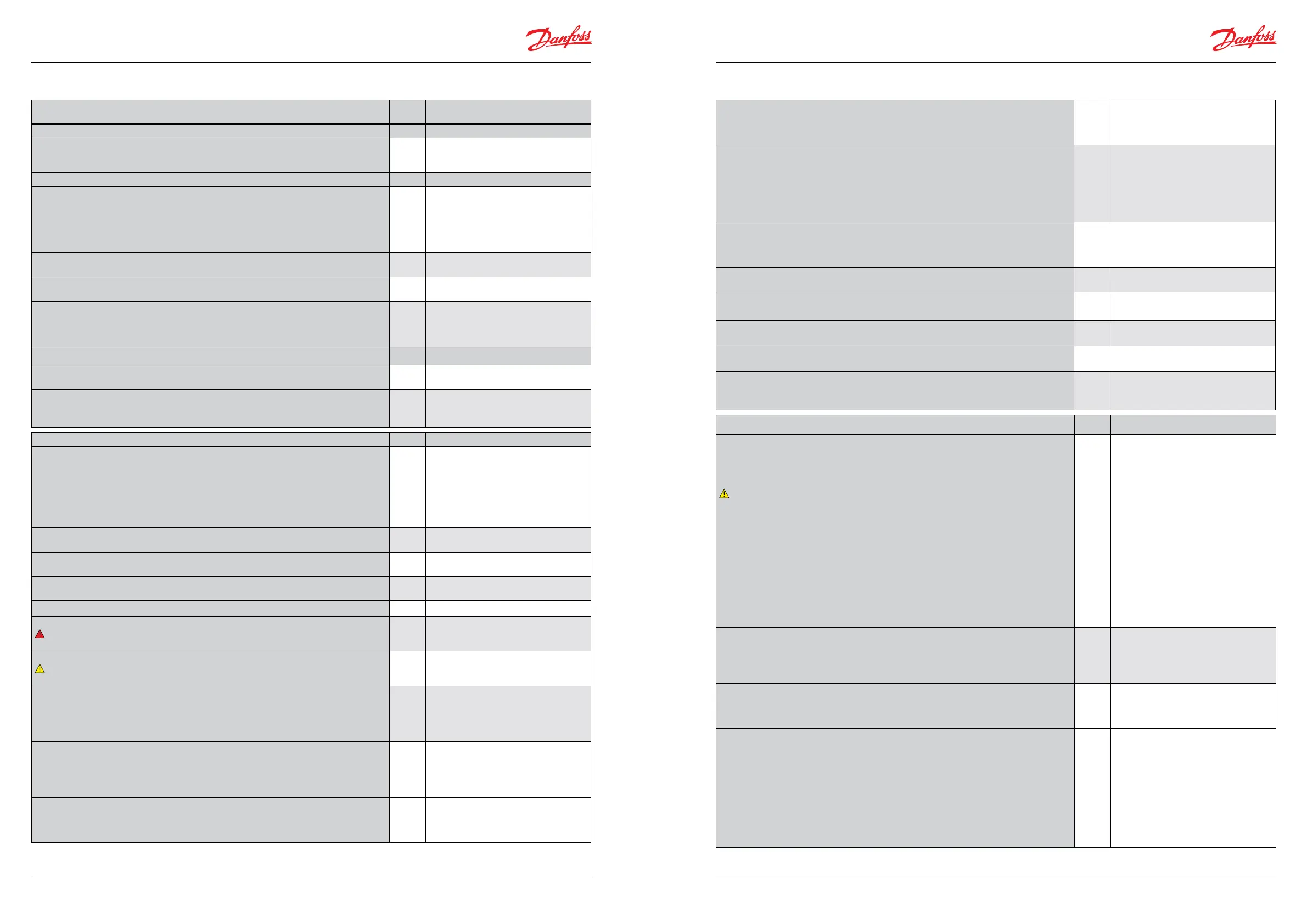

Survey and function (continued)

Damping of amplication near reference value

This setting damps the normal amplication Kp, but only just around the reference

value. A setting of 0.5 will reduce the KP value by half.

The value should only be changed by specially-trained sta.

n19 Kp Min

Amplication factor for the superheat

This setting determines the valve’s opening degree as a function of the change in

evaporating pressure. An increase of the evaporating pressure will result in a reduced

opening degree. When there is a drop-out on the low-pressure thermostat during

startup, the value must be raised slightly. If there is pendling during start-up, the

value must be reduced slightly.

The value should only be changed by specially-trained sta.

n20 Kp T0

Denition of superheat regulation (Ref. section "Operation")

1: Lowest permissible superheat (MSS). Adaptive regulation.

2: Load-dened superheat. The reference is established based on the line formed by

the three points: n09, n10 and n22.

n21 SH mode

Value of min. superheat reference for loads under 10%

(The value must be smaller than "n10").

n22 SH Close

Max. opening degree

The valve’s opening degree can be limited. The value is set in %.

n32 ETS OD% Max

Number of steps from 0% to 100% open (User-dened valve, n03 =5)

(Automatic setting when valve is selected in n03).

n37 Max. steps (100 to 6000 step)

Spindle stroke speed (number of steps per second)

(Automatic setting when valve is selected in n03).

n38 Steps/sec (5 to 300 step/sec)

Integration time for the inner loop gain

Used only when o56 = 2

The value should only be changed by specially-trained sta.

n44 TnT0 sec

Miscellaneous Miscellaneous

Address/data communication

The controller must always have an address. The factory-set address is 240.

When an external display is connected, the display itself will nd the address of the

controller so that communication can take place.

Note:

A display and a system unit must not be connected at the same time.

The display will not be able to communicate in this situation.

If the controller is to be part of a network with other controllers and a system unit, the

controller‘s address must be within the range 1 to 200.

This address must EITHER be set via a display before it is connected to the data com-

munication and a scan of the network is performed

OR the network is connected and a scan is performed. The address is then set after-

wards. A new scan is performed so that the new address is known.

Requirements for the installation and data communication cable are discussed in the

separate document no. "RC8AC".

The controller can be operated via the

system unit and AK service tool.

It cannot be operated via AKM type

system software.

o03 Unit addr.

The address is set between 0 and 200.

(When the address is set, the system

the system unit’s scan function should

be activated)

Application mode

1: The controller receives signals from another controller and must control the valve’s

opening degree.

2: Superheat regulation.

o61 Appl. mode

Input signal for external control of the valve‘s opening degree

Only used if o61 is set to 1.

Denition of the signal's range.

0: No signal

1: 0-20 mA

2: 4-20 mA

3: 0-10 V

4: 1-5 V

(At the lower value the valve will be closed. At the upper value the value will be fully

open. There is a linear relationship between the signal and the opening degree. The

height of the valve is not taken into account.)

o10 AI type

©Danfoss A/S (AC-MCI / sw), 2014-03 DKRCC.PS.RP0.A1.02/520H7142 1918 DKRCC.PS.RP0.A1.02/520H7142 ©Danfoss A/S (AC-MCI / sw), 2014-03

Manual Superheat controller type EKD 316Manual Superheat controller type EKD 316

Loading...

Loading...